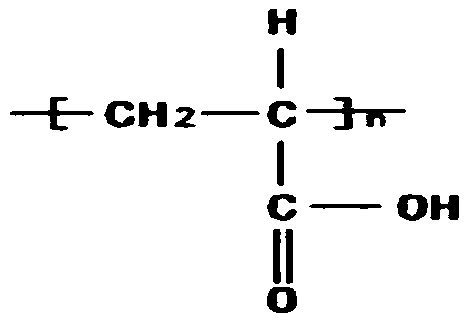

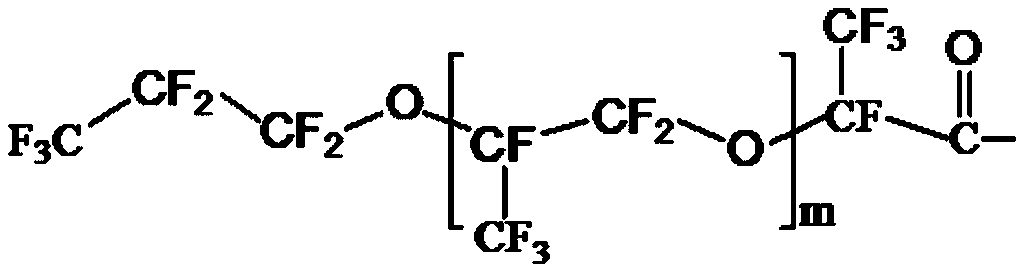

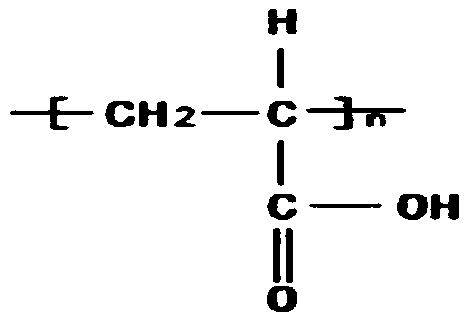

Fluorine-containing water-soluble polymer material for producing top anti-reflection film in photoetching process

A water-soluble polymer and molecular weight technology, applied in the field of photoresist, can solve the problems of poor water solubility and inconvenient combination at the same time, and achieve the effects of improving the yield rate of photolithography, reducing interference, and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Dissolve 2.9g of fluorine-containing water-soluble polymer material with Mw=2600 in water at 30-50°C, stir for 2-8 hours, and prepare a clear and transparent solution with a concentration of 4%.

[0026] Step 2: Gradually add a certain amount of perfluoro linear carboxylic acid to the prepared clear and transparent solution, heat and reflux under reduced pressure for 6 hours, continue to add perfluoro linear carboxylic acid during the reflux process, and adjust the pH of the solution to 4 at the same time; Pure water to adjust the solute solid content in the solution to 3%; then adjust the fluorine content to 30% of the solute in the solution.

[0027] Step 3: Add a certain amount of organic amine tetramethylammonium hydroxide and aspartic acid solution, the solution concentration should be 4%, to adjust the pH of the solution to 2-3, and obtain a clear and transparent solution at the same time, so as to complete the overall fluorine content adjustment.

Embodiment 2

[0029] Step 1: Dissolve 2.9g of fluorine-containing water-soluble polymer material with Mw=2600 in water at 30-50°C, stir for 2-8 hours, and prepare a clear and transparent solution with a concentration of 4%.

[0030] Step 2: Gradually add a certain amount of sulfonic acid to the prepared clear and transparent solution, heat and reflux under reduced pressure for 6 hours, continue to add sulfonic acid during the reflux process, and adjust the pH of the solution to 4 at the same time; at the same time, add ultrapure water to adjust the solute in the solution The solid content is 3%; then adjust the fluorine content to 30% of the solution solute.

[0031] Step 3: Add a certain amount of organic amine tetramethyl hydroxide and aspartic acid solution, the solution concentration should be 4%, to adjust the pH of the solution to 2-3, and obtain a clear and transparent solution at the same time, so as to complete the adjustment of the overall fluorine content Adjustment.

Embodiment 3

[0033] Step 1: Dissolve 2.9g of fluorine-containing water-soluble polymer material with Mw=2600 in water at 30-50°C, stir for 2-8 hours, and prepare a clear and transparent solution with a concentration of 4%.

[0034] Step 2: Gradually add a certain amount of perfluoropolyether carboxylic acid to the prepared clear and transparent solution, heat and reflux under reduced pressure for 6 hours, continue to add perfluoropolyether carboxylic acid during the reflux process, and adjust the pH of the solution to 4 at the same time; Pure water to adjust the solute solid content in the solution to 3%; then adjust the fluorine content to 30% of the solute in the solution.

[0035] Step 3: Add a certain amount of organic amine tributylammonium hydroxide and glutamic acid solution, the solution concentration should be 4%, to adjust the pH of the solution to 2-3, and obtain a clear and transparent solution at the same time, so as to complete the adjustment of the overall fluorine content ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com