Preparation method of spherical ag@t-znow powder and method and application of high dielectric polymer composite film

A composite film and polymer technology, which is applied in the parts of fixed capacitors and the dielectric of fixed capacitors, can solve the problem that quantum tunneling effect is difficult to meet the requirements of dielectric properties, achieve excellent electrical properties, improve capacitance, The effect of improving the dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: The preparation method of spherical Ag@T-ZnOw powder in this example is carried out according to the following steps:

[0033] Step 1. Mix 0.25g of silver nitrate and 1.0g of polyvinylpyrrolidone, then add 100mL of ethylene glycol, heat up to 150°C while stirring, keep warm for 2h, and cool naturally to 70°C;

[0034] Step 2, then add 2g of tetraacicular zinc oxide, keep warm at 70°C and stir at 1500rmp for 2h, then cool to room temperature;

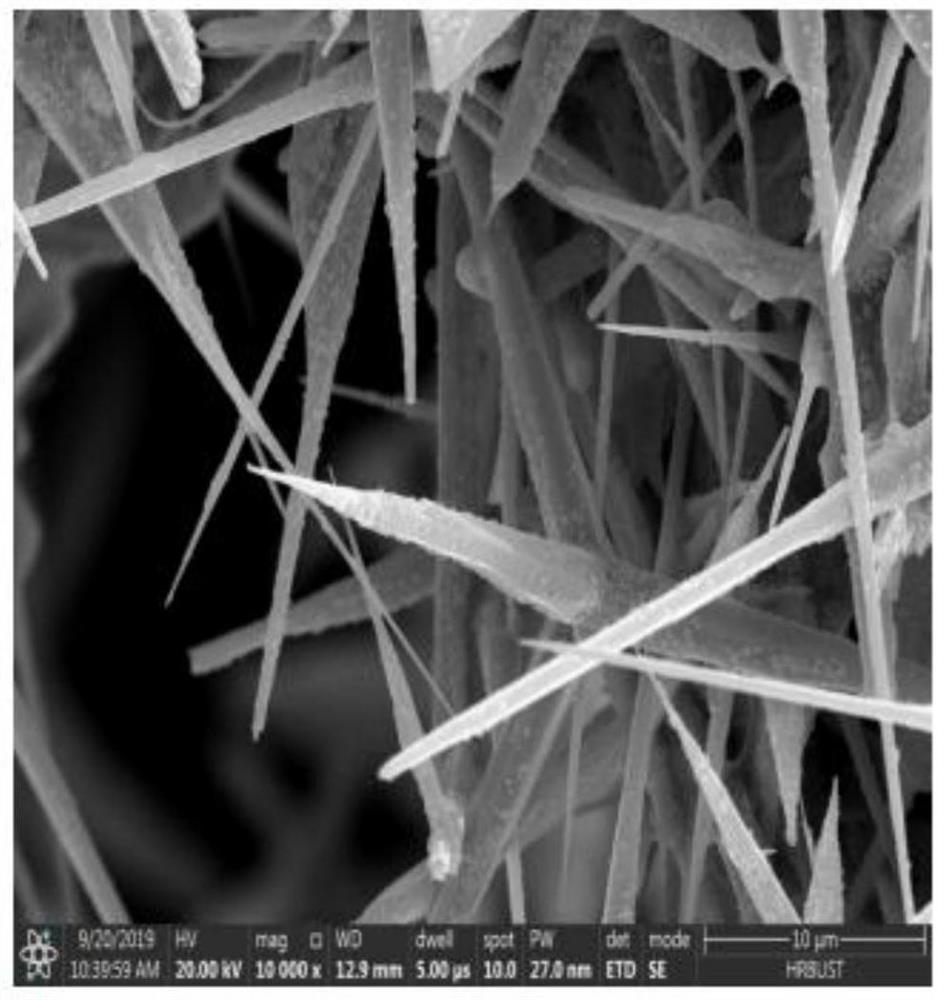

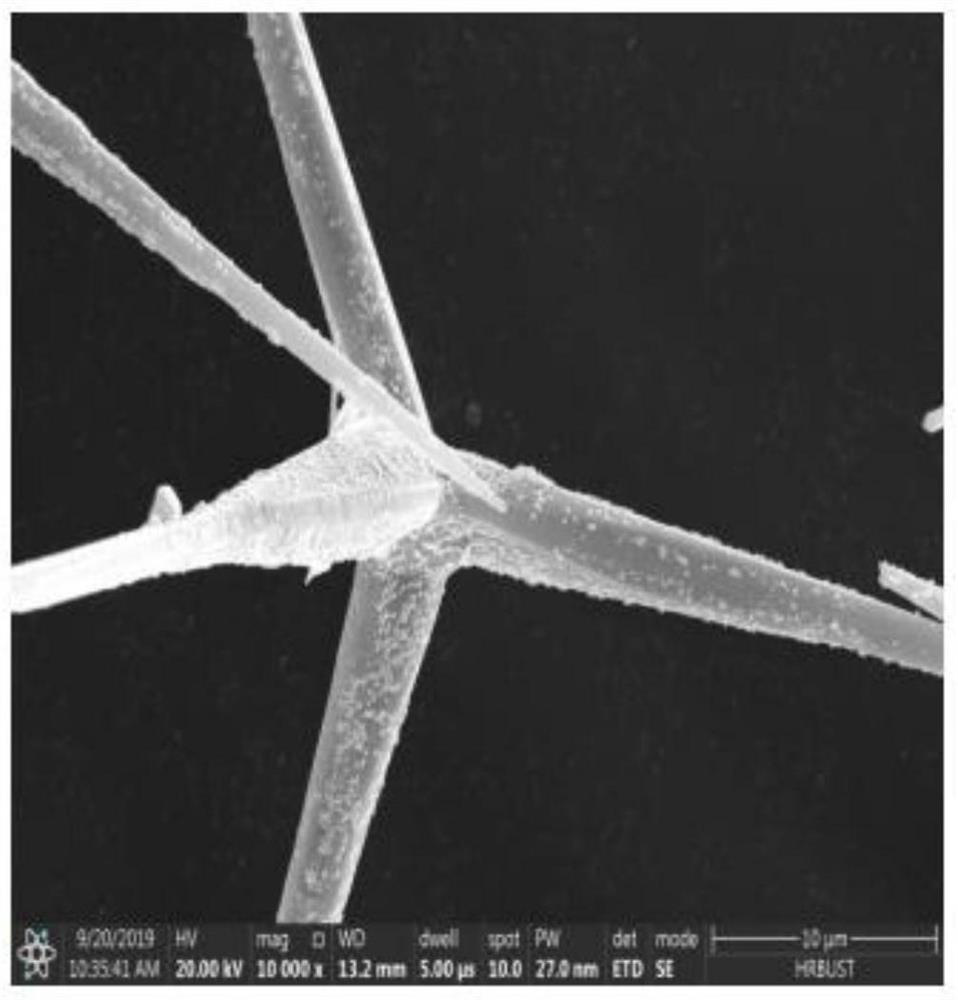

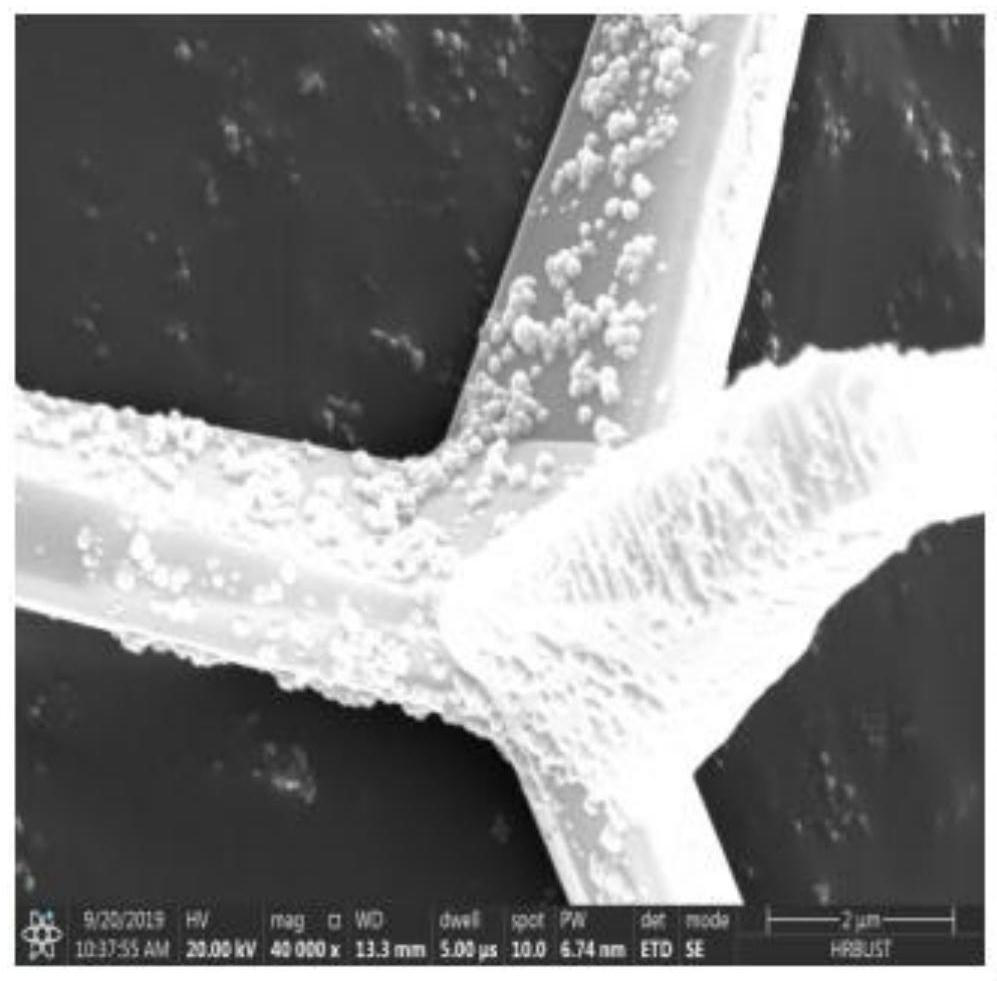

[0035] Step 3, then wash with ethanol solution with a volume concentration of 95%, centrifuge at 2000rpm for 3 times, and then dry at 80°C to obtain Ag@T-ZnOw powder, such as Figures 1a-1d As shown, it can be seen from the figure that the surface of the tetrapod-shaped zinc oxide is covered with spherical nano-silver particles, and the appearance is good.

[0036] The method for preparing a high dielectric polymer composite film from the spherical Ag@T-ZnOw powder prepared by the above method is completed through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com