Modified styrene-butadiene rubber hose with high gas barrier property and preparation method thereof

A gas barrier and styrene-butadiene rubber technology, applied in the field of rubber hoses, can solve the problems of poor air tightness and limitation of styrene-butadiene rubber air hoses, and achieve the effect of overcoming weak mechanical strength, good mechanical strength and improving gas barrier performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

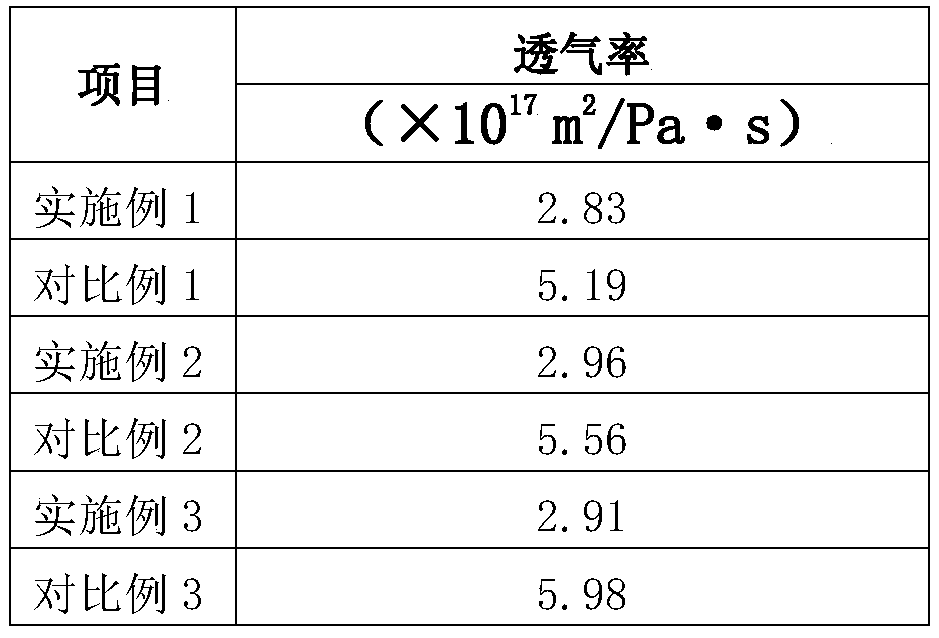

Examples

Embodiment 1

[0022] According to 50kg natural rubber (smoke sheet rubber No. 3), 60kg styrene-butadiene rubber, 7kg butadiene rubber, 7kg zinc oxide, 2kg stearic acid, 3kg anti-aging agent SP-C, 1kg anti-aging agent MB, 60kg modified sheet rector Stone, 40kg modified kaolin, 5kg silane coupling agent (KH-550), 1kg xylene resin, 1kg accelerator M, 1.5kg accelerator DM, 0.5kg accelerator D, 2.5kg sulfur The mass ratio weighs each After the raw materials, firstly mix the modified flaky rectorite and modified kaolin evenly to get the filling powder; then mix the natural rubber, styrene-butadiene rubber and butadiene rubber on the open mill for 5 minutes, wait until the temperature is uniform and wrap the rolls, Slowly add 1 / 3 weight filler powder, silane coupling agent, xylene resin, anti-aging agent (anti-aging agent SP-C and anti-aging agent MB), accelerator (accelerator M, accelerator DM and accelerator D) in sequence , 1 / 3 weight of filling powder, after eating the powder, add stearic acid...

Embodiment 2

[0028]According to 45kg natural rubber (No. 3 smoked sheet rubber), 55kg styrene-butadiene rubber, 5kg butadiene rubber, 6kg zinc oxide, 1.5kg stearic acid, 2kg anti-aging agent SP-C, 0.6kg anti-aging agent MB, 55kg modified sheet Rectorite, 35kg modified kaolin, 4kg silane coupling agent (KH-560), 0.8kg xylene resin, 0.8kg accelerator M, 1.2kg accelerator DM, 0.4kg accelerator D, 2.3kg sulfur After weighing each raw material, first mix the modified flaky rectorite and modified kaolin evenly to obtain the filling powder; then mix the natural rubber, styrene-butadiene rubber and butadiene rubber on the open mill for 3 to 5 minutes, and wait for the temperature After the roll is evenly covered, slowly add 1 / 3 weight of filler powder, silane coupling agent, xylene resin, anti-aging agent (anti-aging agent SP-C and anti-aging agent MB), accelerator (accelerator M, accelerator DM and accelerator D), 1 / 3 weight of filling powder, after eating the powder, add stearic acid, 1 / 3 weight...

Embodiment 3

[0034] According to 40kg natural rubber (No. 3 smoked sheet rubber), 50kg styrene-butadiene rubber, 3kg butadiene rubber, 3kg zinc oxide, 1kg stearic acid, 1kg anti-aging agent SP-C, 0.3kg anti-aging agent MB, 50kg modified sheet The mass ratio of supporting stone, 30kg modified kaolin, 3kg silane coupling agent (KH-570), 0.5kg xylene resin, 0.5kg accelerator M, 1kg accelerator DM, 0.3kg accelerator D, 2kg sulfur After each raw material, first mix the modified flaky rectorite and modified kaolin evenly to obtain the filling powder; then mix the natural rubber, styrene-butadiene rubber and butadiene rubber on the open mill for 3 minutes, wait for the temperature to be uniform and roll-wrapped , slowly add 1 / 3 weight of filler powder, silane coupling agent, xylene resin, anti-aging agent (anti-aging agent SP-C and anti-aging agent MB), accelerator (accelerator M, accelerator DM and accelerator D ), 1 / 3 weight of filler powder, after eating the powder, add stearic acid, 1 / 3 weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com