Preparation method for improving fermentation efficiency of citric acid

A technology of fermentation efficiency and fermentation method, which is applied in the preparation field of improving citric acid fermentation efficiency, can solve the problems of high environmental protection treatment cost, low conversion rate, low yield, etc., to reduce production grain consumption, reduce waste water discharge, and reduce extraction effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

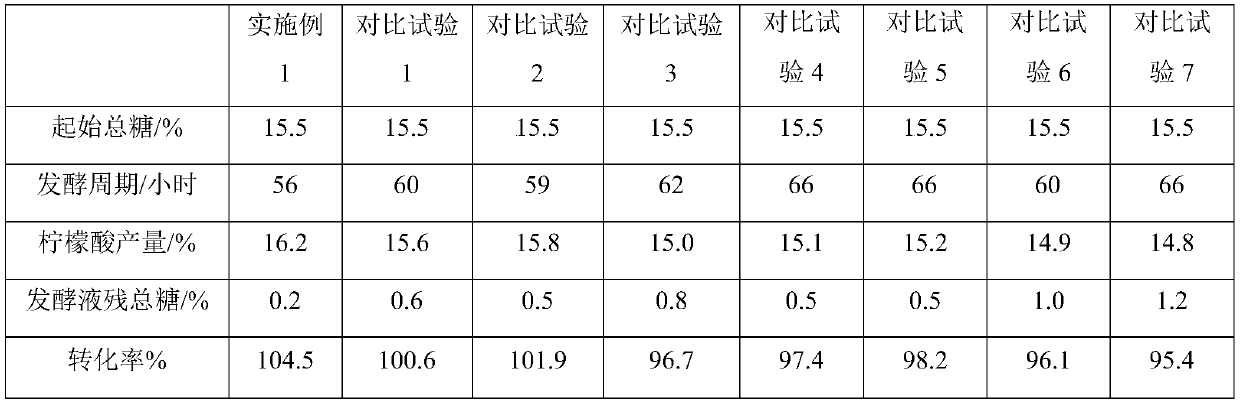

Examples

Embodiment 1

[0021] A preparation method for improving the fermentation efficiency of citric acid:

[0022] ① Preparation of liquid enzymolysis solution

[0023] Take 5300kg of corn liquefied liquid with a dry matter concentration of 25%, control the temperature at 58℃, adjust the pH to 5.2, and add 800g glucoamylase, 80g fungal enzyme, 80g xylanase, 160g acid protease, and temperature control 58℃ enzyme in sequence Dissolve for 24 hours to prepare a liquid enzymatic hydrolysis solution;

[0024] ② Preparation of seed liquid

[0025] Dilute the 500kg liquid enzymatic hydrolysate in step ① with water to 9.5% of total sugar, sterilize at 121°C for 30 minutes, then cool to 35°C, insert citrate-producing Aspergillus niger spores, aeration ratio of 0.5v / v·min, stir Rotate speed 200r / min, culture for 24 hours, pH value drops to 2.0, citric acid 0.95%, bacteria ball size is uniform, hyphae are short and thick, which can be used for fermentation inoculation.

[0026] ③ Preparation of fermentation medium

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com