A kind of recycling smelting process of tin-containing material

A material and process technology, applied in the field of tin-containing material recovery and smelting process, can solve the problems of reducing social and economic benefits, reducing the value of resource recovery, and high tin smelting temperature, reducing the amount of flue gas generated, high reaction efficiency, and smelting. The effect of less slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

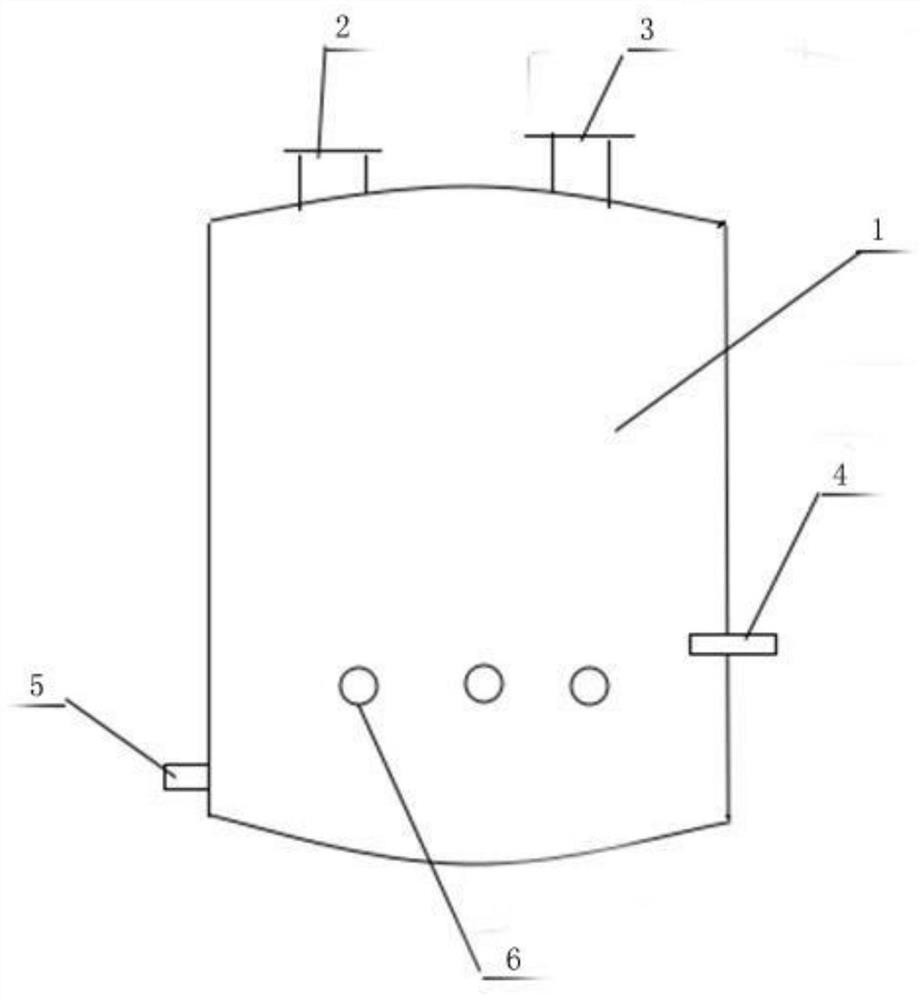

Image

Examples

Embodiment 1

[0040] A recovery smelting process (bottom blowing furnace) for tin-containing materials, the process comprises the following steps:

[0041] (1) Take tin-containing materials (30-50% tin, 10-30% lead) and ball mill to 40 mesh, then ball-mill tin-containing materials, pulverized coal, and soda ash according to the mass ratio of ingredients 20:1:2 and mix and granulate ;

[0042] (2) Add the granulation of step (1) into the furnace from the feed port of the smelting furnace, and smelt at 800-1000°C; during the smelting process, natural gas is used as fuel and pure oxygen is used as combustion-supporting gas by the spray gun at the bottom of the smelting furnace Spray into the metal layer in the furnace, and the pressure of natural gas and pure oxygen is 0.2-0.4MPa;

[0043] Among them, the ratio of the gaseous pure oxygen to the mixed granulation material into the furnace is 80-120m 3 / ton of material, the volume ratio of natural gas and pure oxygen is 0.45-0.5; the content ...

Embodiment 2

[0047] A recovery smelting process (side-blown furnace) for tin-containing materials, the process comprises the following steps:

[0048] (1) Take the tin-containing material (30-50% tin, 10-30% lead) and ball mill to 40 mesh, then ball-mill the tin-containing material, pulverized coal, and soda ash according to the mass ratio of ingredients 20:4:3 and mix and granulate ;

[0049] (2) Add the granulation of step (1) into the furnace from the feed port of the melting furnace, and smelt at 800-1000°C; during the smelting process, coal gas is used as fuel and pure oxygen is used as combustion-supporting gas from the side of the smelting furnace. The spray gun is sprayed into the slag layer in the furnace, and the pressure when the gas and pure oxygen are introduced is 0.2-0.3MPa;

[0050] Among them, the ratio of the gaseous pure oxygen to the mixed granulation material into the furnace is 80-120m 3 / ton of material, the volume ratio of coal gas to pure oxygen is 2.5-3.5; the ...

Embodiment 3

[0054] A recovery smelting process (bottom blowing furnace) for tin-containing materials, the process comprises the following steps:

[0055] (1) Take the tin-containing material (30-50% tin, 10-30% lead) and ball mill to 40 mesh, then ball-mill the tin-containing material, pulverized coal, and soda ash according to the mass ratio of ingredients 20:2:2.5 and mix and granulate ;

[0056] (2) Add the granulation of step (1) into the furnace through the feed port of the melting furnace, and carry out melting under the condition of 800-1000°C; during the melting process, coal gas is used as fuel and pure oxygen is used as combustion-supporting gas by the spray gun at the bottom of the melting furnace Spray into the metal layer in the furnace, and the pressure when the gas and pure oxygen are introduced is 0.3-0.4MPa;

[0057] Among them, the ratio of the gaseous pure oxygen to the mixed granulation material into the furnace is 80-120m 3 / ton of material, the volume ratio of coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com