Manufacturing method suitable for mouse tendon tissue paraffin section

A production method and paraffin section technology, applied in the field of biological tissue production, can solve the problems of hard touch, incomplete tissue, white tissue, etc., and achieve the effects of complete tissue structure, inhibition of shrinkage, and strong penetration ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

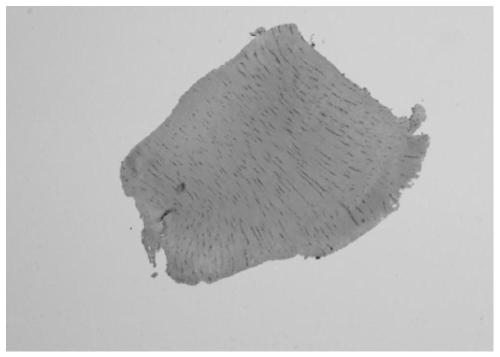

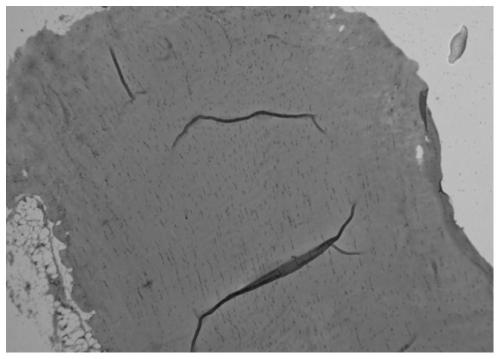

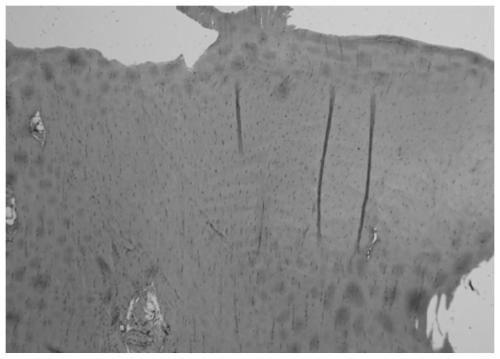

[0037] Example 1 Preparation of Paraffin Sections of Rat Tendon Tissue

[0038] The making of mouse tendon tissue paraffin section comprises the following steps:

[0039] Put the mouse tendon tissue into the fixative solution (a mixture of paraformaldehyde with a mass concentration of 4%, a volume fraction of 95% and a mixture of glacial acetic acid with a volume fraction of 5%) for 36 hours, and then transfer to a preservation solution (a volume fraction of Store in a mixture of 70% ethanol and 5% glacial acetic acid) for 1 day, then put the tissue directly into graded ethanol and use an automatic dehydrator to dehydrate and infiltrate, put it into the tissue embedding frame, add melted paraffin, and paraffin after natural cooling After solidification and forming, the tissue wax block was sliced into 3 μm sections with a paraffin microtome. After sectioning, the slices were spread in distilled water at 40° C. and baked to obtain the paraffin slices of the tendon tissue.

Embodiment 2

[0040] Example 2 Preparation of Paraffin Sections of Rat Tendon Tissue

[0041] The making of rat tendon tissue paraffin section comprises the following steps:

[0042] The rat tendon tissue was fixed in a fixative solution (a mixture of 3% mass concentration, 90% volume fraction of paraformaldehyde and 10% volume fraction of glacial acetic acid) for 24 hours, and then transferred to a preservation solution (volume fraction of The mixture of 68% ethanol and glacial acetic acid with a volume fraction of 7%) was preserved for 2 days, and then the tissue was directly dehydrated and infiltrated in graded ethanol with an automatic dehydrator, put into a tissue embedding frame, added melted paraffin, and paraffin wax after natural cooling After solidification and forming, the tissue wax block was sliced into 3 μm sections with a paraffin microtome. After sectioning, the slices were spread in distilled water at 40° C. and baked to obtain the paraffin slices of the tendon tissue.

Embodiment 3

[0043] Example 3 Preparation of Paraffin Sections of Rat Tendon Tissue

[0044] The making of rat tendon tissue paraffin section comprises the following steps:

[0045] The rat tendon tissue was fixed in a fixative solution (a mixture of 5% mass concentration, 90% volume fraction of paraformaldehyde and 10% volume fraction of glacial acetic acid) for 48 hours, and then transferred to a preservation solution (volume fraction of Store in a mixture of 72% ethanol and 3% glacial acetic acid) for 2 days, then put the tissue directly into graded ethanol and dehydrate and infiltrate it with an automatic dehydrator, put it into the tissue embedding frame, add melted paraffin, and paraffin after natural cooling After solidification and forming, the tissue wax block was sliced into 3 μm sections with a paraffin microtome. After sectioning, the slices were spread in distilled water at 40° C. and baked to obtain the paraffin slices of the tendon tissue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com