Electrochemical hydrogen sulfide sensor and preparation method

A hydrogen sulfide sensor, electrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of cumbersome production process of sensor electrodes, expensive precious metals, labor and financial resources, and achieve good selectivity and cost. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

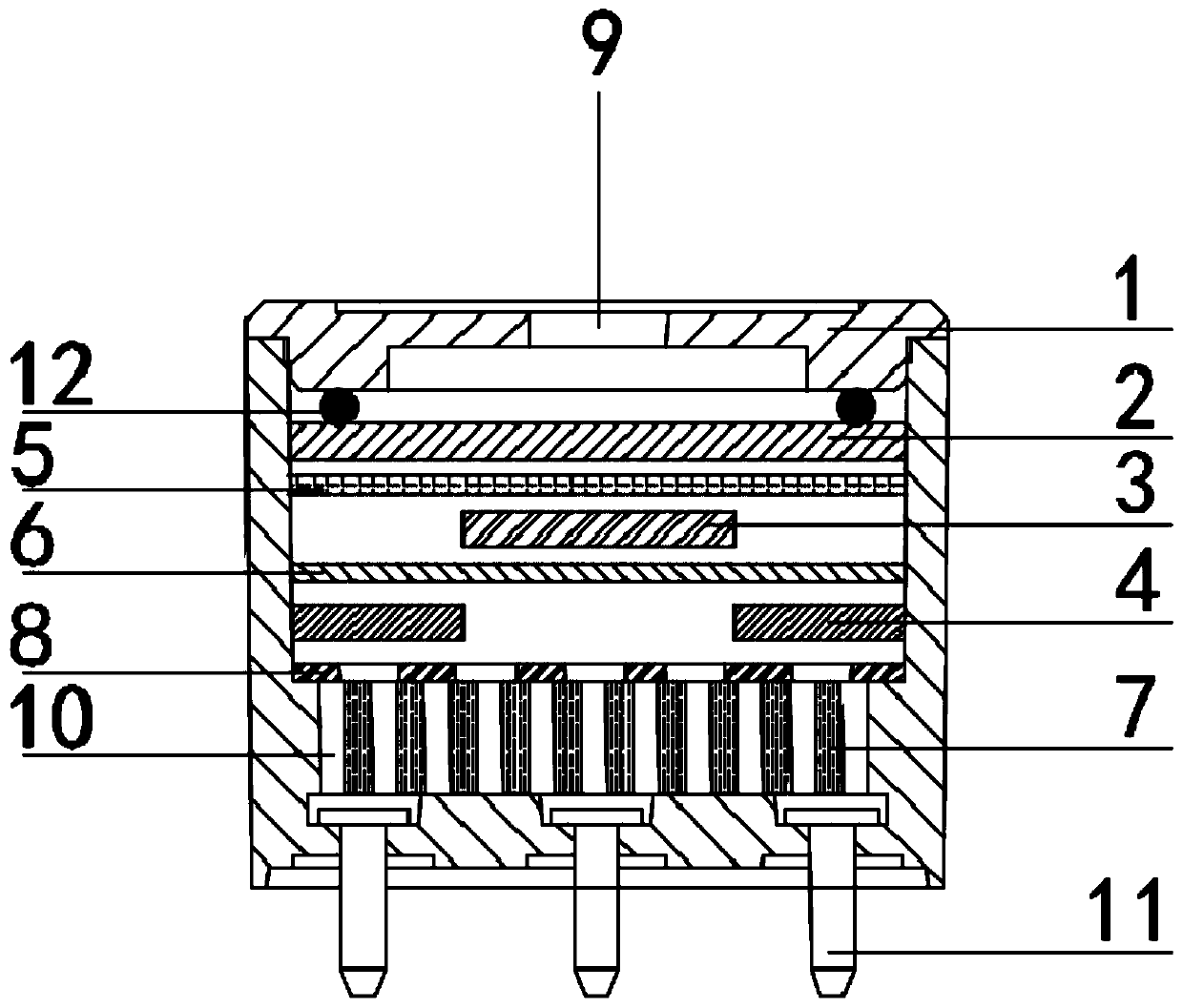

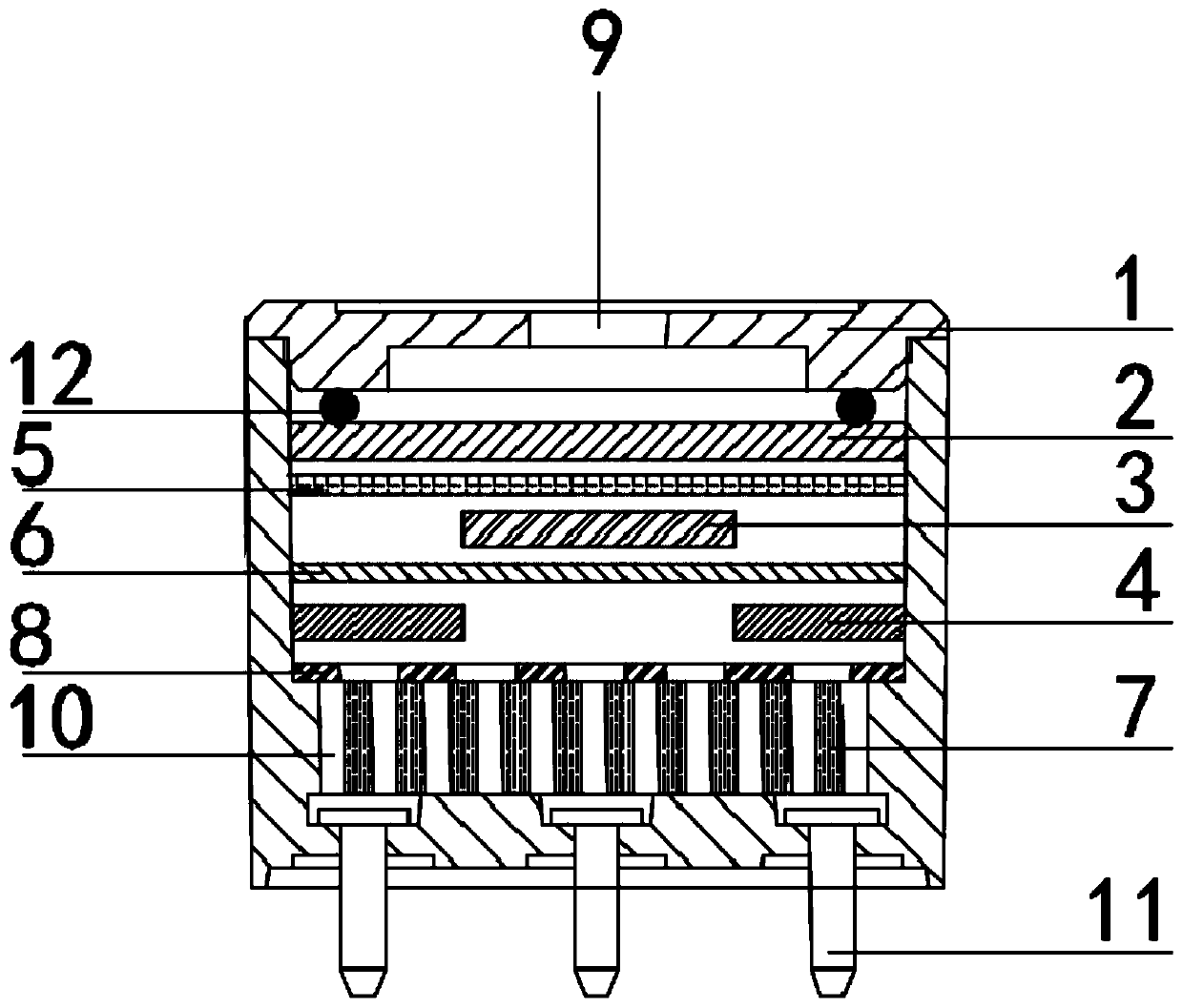

[0050] A kind of preparation method of electrochemical hydrogen sulfide sensor of preferred embodiment of the present invention, comprises the following steps:

[0051] S1: Take 0.5g of platinum ruthenium black, add 2g of activated carbon powder, mix evenly, add polytetrafluoroethylene emulsion, and magnetically stir for 48 hours to prepare electrode slurry;

[0052] S2: Coat the electrode slurry on the polytetrafluoroethylene film with a wire rod, and dry at 60°C for 24 hours to obtain an electrode;

[0053] S3: Use a punch to cut out two disc-shaped electrodes with a diameter of 18mm, one of which is used as the working electrode 2, and the other disc-shaped electrode is cut out from its center using a 6mm circular hollow cutting head The small disc-shaped electrode is used as the reference electrode 3, and the cut out concentric ring-shaped electrode is used as the counter electrode 4;

[0054] S4: Assembling, filling liquid-absorbing material 3 7 in liquid storage tank 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com