Composite film packaging method of perovskite solar cell

A technology of solar cells and composite thin films, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as PSC failure and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

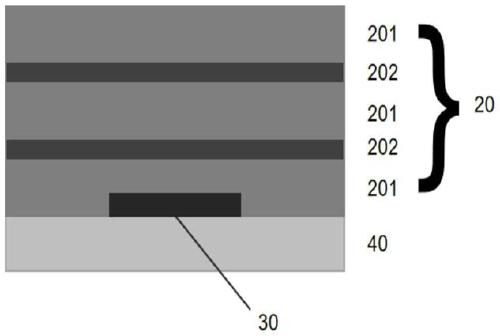

[0044] refer to figure 1 As shown, Embodiment 1 of the present invention provides a thin film encapsulation structure of a perovskite solar cell on a rigid substrate, which structure includes a rigid substrate 40, a perovskite solar cell 30 disposed on the substrate 40, and a perovskite solar cell disposed on the perovskite solar cell. On the solar cell 30 and used to protect the composite barrier layer of the perovskite solar cell 30 in the process of encapsulation and practical application, the composite barrier layer 20 (including a multi-layer laminated structure of an organic barrier layer 201 and an inorganic barrier layer 202, the uppermost One layer is an organic barrier layer 201).

[0045] Wherein, the rigid substrate 40 is a glass substrate, and the perovskite solar cell 30 is a planar perovskite solar cell in an organic metal halide perovskite solar cell (structure: glass substrate / ITO / SnO 2 / MaPbI 3 / spiro-MeOTAD / Ag). The composite barrier layer 20 includes thr...

Embodiment 2

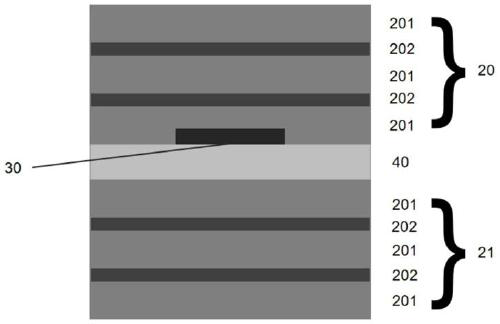

[0056] refer to image 3 As shown, the present embodiment provides a film encapsulation structure of a perovskite solar cell on a flexible substrate, the structure includes a flexible substrate 40, and a cap set on the lower surface of the substrate for protecting the perovskite solar cell 30 during practical application. The base encapsulation barrier layer 21 is disposed on the upper surface of the perovskite solar cell 30 and used to protect the composite barrier layer 20 of the perovskite solar cell 30 during the encapsulation process. Among them, the composite barrier layer 20 includes 3 layers of organic barrier layers 201 and 2 layers of barrier layers 202 arranged between two adjacent layers of organic barrier layers. The two layers between adjacent two organic barrier layers have barrier layer 202 or not. The structure of the solar cell is: flexible substrate / Au / SnO 2 / MaPbI 3 / spiro-MeOTAD / Ag.

[0057] Specific steps are as follows:

[0058] 1) Prepare 6 PET sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com