Cathode material for high-capacity lithium-sulfur battery, preparation method and application thereof

A technology for lithium-sulfur batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult large-scale production, complex preparation process of porous carbon materials, high cost, etc., and achieves mild preparation process conditions and is conducive to The effect of mass production and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

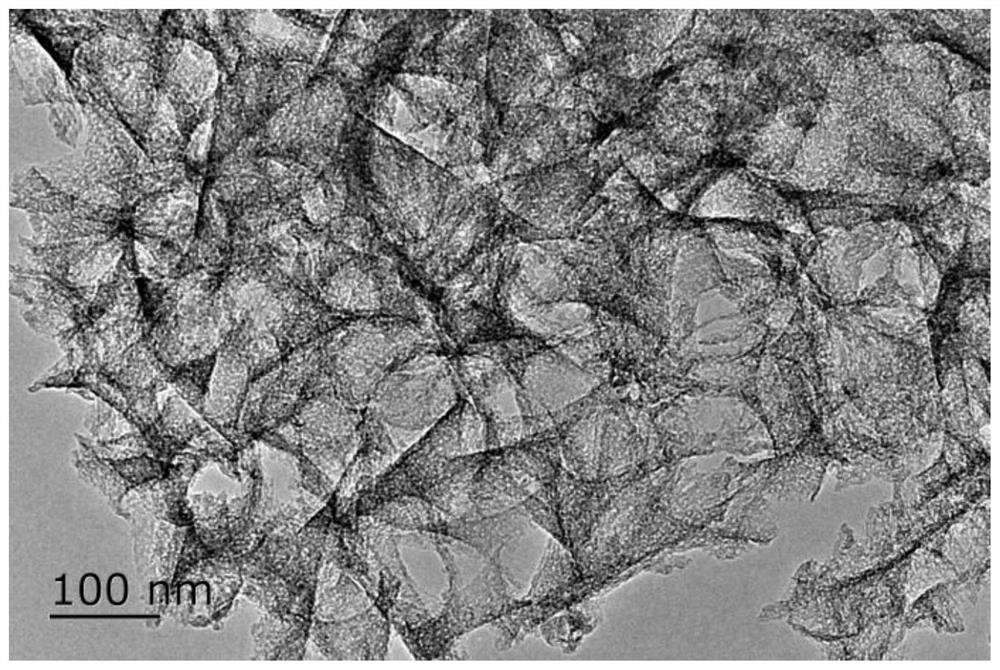

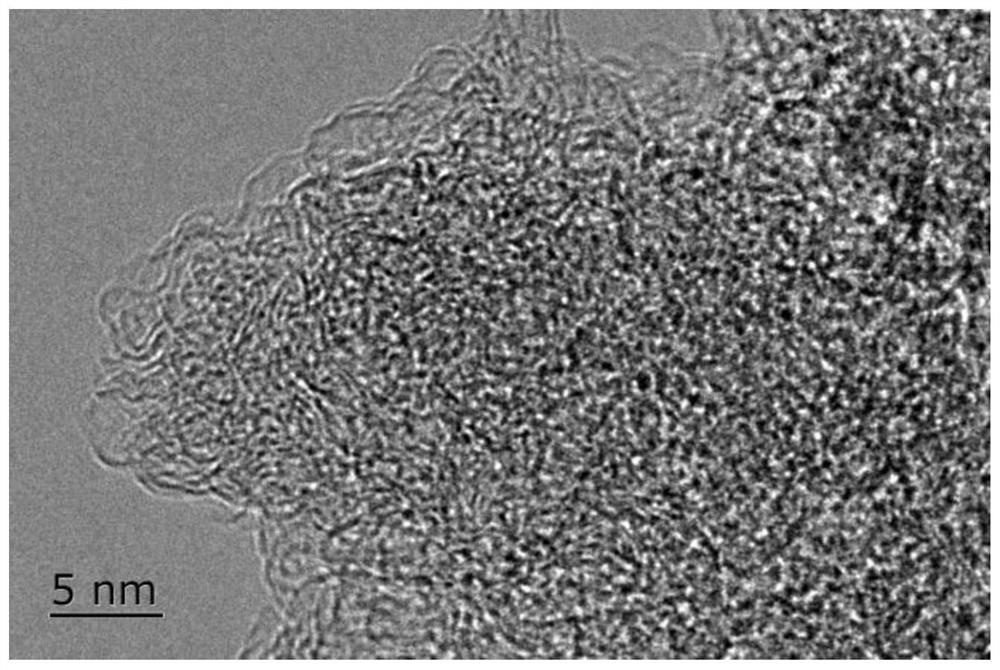

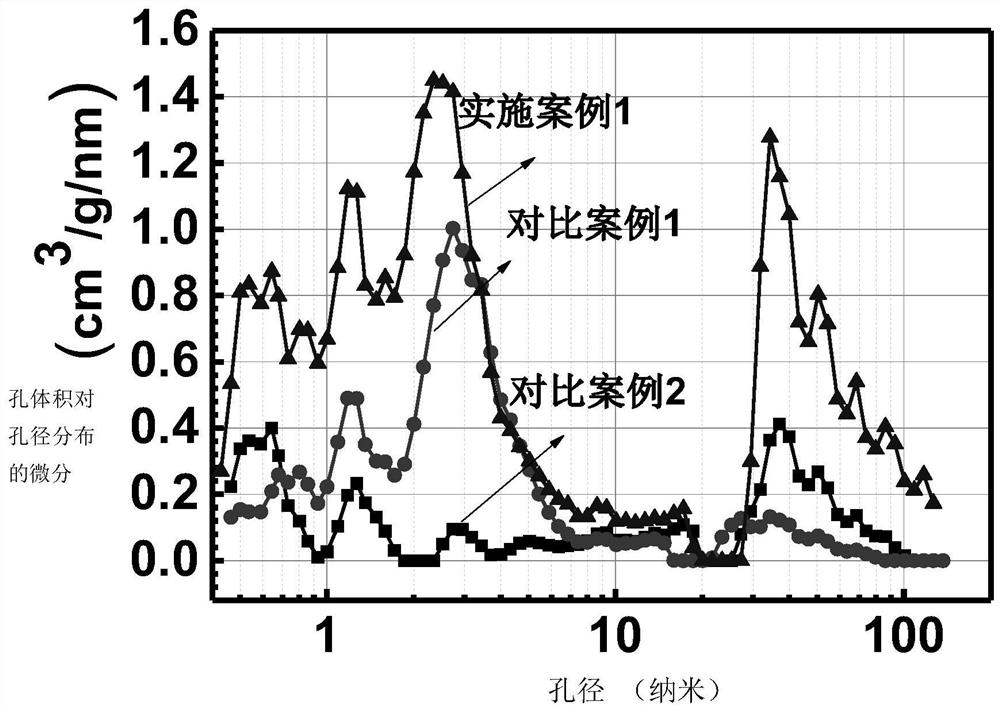

[0050] A preparation method of a high-capacity lithium-sulfur battery positive electrode material (HPGC / S), comprising the following steps:

[0051] Step 1, preparing hierarchically porous graphitized carbon:

[0052] 1-1. Add 50g of ion exchange resin to 200ml of cobalt chloride aqueous solution with a concentration of 0.2mol / L, stir for 2 hours, evaporate in a water bath at 80°C for 10 hours under stirring conditions, dry at 80°C for 12 hours, and pulverize Finally, the resin for adsorbing cobalt ions is obtained, and the particle diameter of the resin is 1 to 50 microns;

[0053] 1-2, uniformly disperse 100 g of potassium hydroxide in 400 ml of absolute ethanol to obtain a potassium hydroxide ethanol solution, add the resin obtained in step 1 into the potassium hydroxide ethanol solution and soak for 10 hours, and filter to obtain the first product;

[0054] 1-3. Dissolve 100g of calcium hydroxide in 400ml of water to obtain an aqueous solution of calcium hydroxide, add th...

Embodiment 4~6

[0065] A preparation method of a high-capacity lithium-sulfur battery positive electrode material (HPGC / S), comprising the following steps:

[0066] Step 1, prepare hierarchically porous graphitized carbon according to Step 1 in Embodiments 1 to 3:

[0067] Step 2, mixing the multi-level porous graphitized carbon obtained in step 1, sublimated sulfur, conductive additives and bonding agent evenly, wherein the conductive additive is CNT, and the bonding agent is polyacrylonitrile (PAN), by mass percentage, more The mass ratios of hierarchically porous graphitized carbon, sublimed sulfur, binders and conductive additives are shown in Table 2.

[0068] Table 2

[0069]

[0070] The method for preparing the above-mentioned high-capacity lithium-sulfur battery positive electrode material into a positive electrode comprises the following steps: coating the high-capacity lithium-sulfur battery positive electrode material prepared above on a current collector, drying in a vacuum o...

Embodiment 7~8

[0073] A preparation method of a high-capacity lithium-sulfur battery positive electrode material (HPGC / S), comprising the following steps:

[0074] Step 1, prepare hierarchically porous graphitized carbon according to Step 1 in Embodiments 1 to 3:

[0075] Step 2, mixing the hierarchically porous graphitized carbon obtained in step 1, sublimated sulfur, conductive additives and adhesive, wherein the adhesive is polyacrylonitrile (PAN), and the hierarchically porous graphitized carbon is calculated by mass percentage , sublimated sulfur, binder and conductive additive in a mass ratio of 25:60:10:5. The conductive additives of Examples 7 and 8 are shown in Table 3.

[0076] table 3

[0077] Example conductive additive Example 7 CNT Example 8 superP

[0078] The method for preparing the above-mentioned high-capacity lithium-sulfur battery positive electrode material into a positive electrode comprises the following steps: coating the high-capacit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| micropore | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com