PdAg alloy-loaded Ti-SBA-15 catalyst, and preparation method and application thereof

A ti-sba-15, catalyst technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex preparation process, and achieve the effect of simple preparation process, small size and high degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

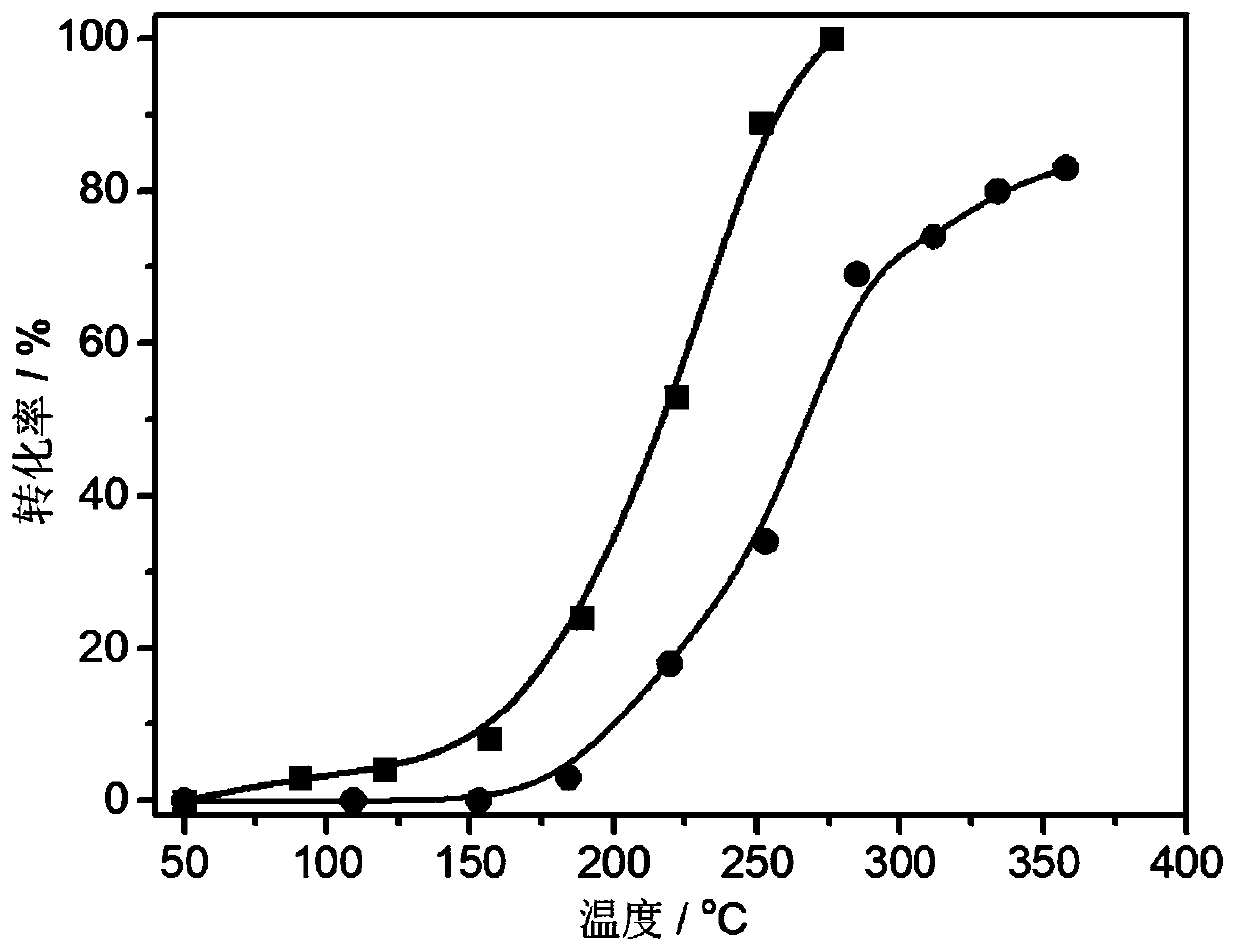

Image

Examples

Embodiment 1

[0029] 1. Dissolve 8.01g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (molecular formula PEO-PPO-PEO, abbreviated as P123) in 300ml hydrochloric acid solution (concentration 0.1mol) / L), stirring at 40°C for 2h to obtain solution A.

[0030] 2. Add 15 mL of ethyl orthosilicate (TEOS) dropwise to solution A, and then add 115 μL of tetrabutyl titanate (the molar ratio of Si in TEOS to Ti in tetrabutyl titanate is 200), Stir at 40℃ for 24h to obtain suspension B; transfer the above suspension B to the reaction kettle, aging at 80℃ for 24h, and then after suction filtration, washing and drying, roasting at 500℃ for 6h (heating rate 2°C / min), and naturally cooled to room temperature to prepare Ti-SBA-15 carrier.

[0031] 3. Put 0.0049gPd(NO 3 ) 2 , 0.0004gAgNO 3 , 0.5g of Ti-SBA-15 carrier obtained in step S2 was dissolved in 300mL ultrapure water, stirred at room temperature for 4h to obtain suspension C, and then 1178μL NaBH was added to suspension ...

Embodiment 2

[0037] 1. Dissolve 8.01 g of P123 in 300 ml of hydrochloric acid solution (concentration 0.1 mol / L), and stir at 40° C. for 2 hours to obtain solution A.

[0038] 2. Add 15 mL of TEOS dropwise to solution A, and then add a certain amount of tetrabutyl titanate (the molar ratio of Si in TEOS to Ti in tetrabutyl titanate is 200), and stir for 24 hours at 40°C , Get suspension B; transfer the above suspension B to the reactor, aging at 80℃ for 24h, and then after suction filtration, washing, drying, roasting at 500℃ for 6h (heating rate is 2℃ / min ), and naturally cooled to room temperature to prepare Ti-SBA-15 carrier.

[0039] 3. Put 0.0043gPd(NO 3 ) 2 , 0.0008gAgNO 3 , 0.5g of Ti-SBA-15 carrier obtained in step S2 was dissolved in 300mL ultrapure water, stirred at room temperature for 4h to obtain suspension C, and then 1175μL NaBH was added to suspension C 4 Solution (concentration 0.1mol / L), continue to stir for 15 minutes, and then perform suction filtration, washing, and drying ...

Embodiment 3

[0041] 1. Dissolve 8.01 g of P123 in 300 ml of hydrochloric acid solution (concentration 0.1 mol / L), and stir at 40° C. for 2 hours to obtain solution A.

[0042] 2. Add 15mL TEOS dropwise to solution A, and then drop a certain amount of tetrabutyl titanate (the molar ratio of Si in TEOS to Ti in tetrabutyl titanate is 200:1), at 40°C Stir for 24 hours to obtain suspension B; transfer the above suspension B to the reactor, aging at 80°C for 24 hours, and then after suction filtration, washing and drying, roasting at 500°C for 6 hours (heating rate is 2°C) / min), and naturally cooled to room temperature to prepare Ti-SBA-15 carrier.

[0043] 3. Put 0.0032gPd(NO 3 ) 2 , 0.0016gAgNO 3 , 0.5g of Ti-SBA-15 carrier obtained in step S2 was dissolved in 300mL of ultrapure water, stirred at room temperature for 4h to obtain suspension C, and then 1171μL of NaBH was added to suspension C 4 Solution (concentration 0.1mol / L), continue to stir for 15 minutes, and then perform suction filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com