Special-shaped stretch-formed heat insulation lunch box and preparation method thereof

A stretch forming and special-shaped technology, which is applied to the special-shaped stretch-formed thermal insulation lunch box and its preparation field, can solve the problems of many defective products, the special-shaped thermal insulation lunch box is prone to defects, and the plate is broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

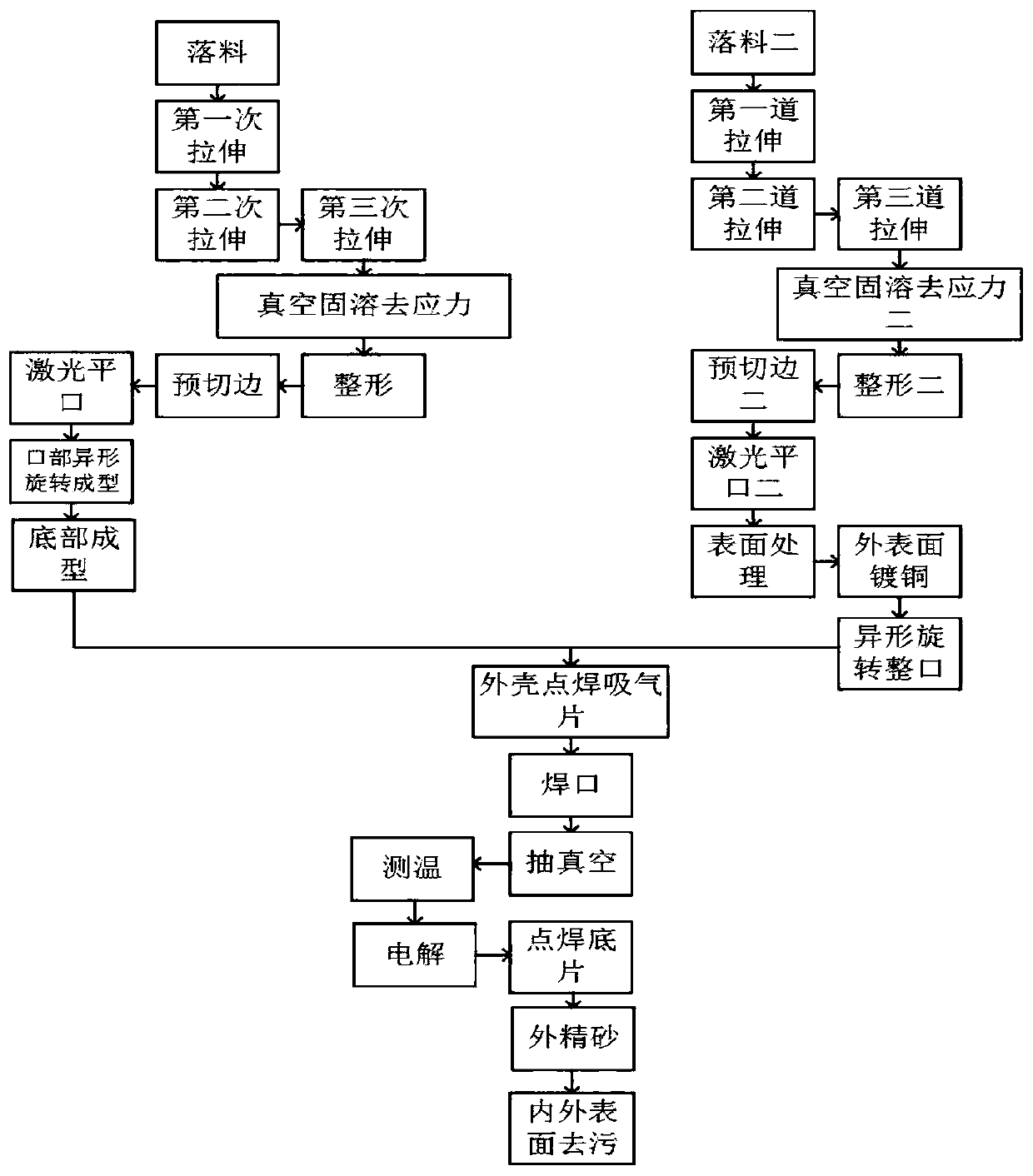

[0076] Embodiment 1: Insulation lunch box preparation one:

[0077] The preparation method of the 18Cr-8Ni stainless steel doped acicular zinc oxide whisker powder that present embodiment uses is as follows:

[0078] Add 12g of zinc powder and 10g of hydrogen peroxide into distilled water, stir with a stirring rate of 700rpm for 2h, then let it stand at room temperature for 36h, and obtain the pretreated zinc powder after filtering. Zinc powder, 30g of 15wt% citric acid solution, 2g of nano After mixing 18Cr-8Ni stainless steel powder, use a 500W mercury lamp as a light source, and after irradiating for 20 minutes, adjust the pH to 7.7±0.3 with sodium hydroxide solution, then continue to irradiate for 40 minutes to obtain 18Cr-8Ni stainless steel doped with needle-shaped zinc oxide crystals beard powder.

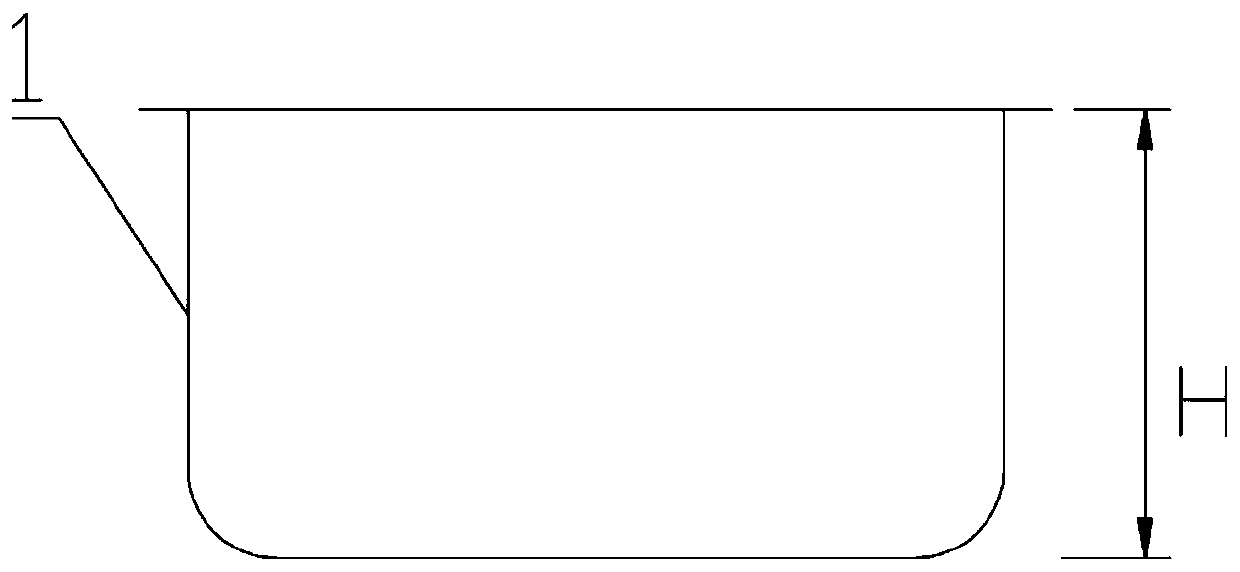

[0079] The thermal insulation lunch box prepared in this embodiment is as figure 1 As shown, the following process steps are included:

[0080] Shaped and constant temper...

Embodiment 2

[0117] Embodiment 2: Insulation lunch box preparation two:

[0118] The preparation method of the 18Cr-8Ni stainless steel doped acicular zinc oxide whisker powder that present embodiment uses is identical with embodiment 1;

[0119] Shaped and constant temperature stretching molding process of shell:

[0120] Blanking is identical with embodiment 1 operation;

[0121] Stretching for the first time: heat the heating ring of the stretching machine to 100°C, the pressure of the main cylinder of the stretching machine is 20Mpa, and the pressure of the lower cylinder is 12Mpa, and the rest of the operations are the same as those in Example 1;

[0122] The second stretching: heat the heating ring of the stretching machine to 90°C, the pressure of the main cylinder of the stretching machine is 13Mpa, and the pressure of the lower cylinder is 8Mpa, and the rest of the operations are the same as in Example 1;

[0123] Stretching for the third time: heat the heating ring of the stret...

Embodiment 3

[0141] Embodiment 3: Insulation lunch box preparation three:

[0142] The preparation method of the 18Cr-8Ni stainless steel doped acicular zinc oxide whisker powder that present embodiment uses is identical with embodiment 1;

[0143] Shaped and constant temperature stretching molding process of shell:

[0144] Blanking is identical with embodiment 1 operation;

[0145] Stretching for the first time: heat the heating ring of the stretching machine to 90°C, the pressure of the main cylinder of the stretching machine is 15Mpa, and the pressure of the lower cylinder is 10Mpa, and the rest of the operations are the same as those in Example 1;

[0146] The second stretching: heat the heating ring of the stretching machine to 70°C, the pressure of the main cylinder of the stretching machine is 10Mpa, and the pressure of the lower cylinder is 5Mpa, and the rest of the operations are the same as in Example 1;

[0147] Stretching for the third time: heat the heating ring of the stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com