Method for preparing liquid organic fertilizer by enzymolysis and fermentation of pigskin

A technology of liquid organic fertilizer and pigskin enzyme, applied in liquid fertilizer, fertilization device, fertilizer mixture, etc., can solve the problems of weakening the meaning and effect of green utilization of leather waste, improve the processing and utilization capacity, increase crop yield, and high fertilizer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

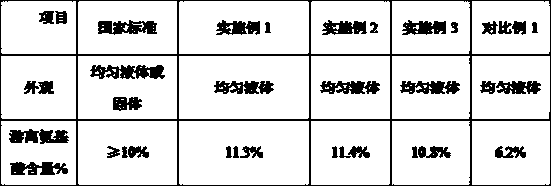

Embodiment 1

[0019] A method for preparing liquid organic fertilizer by enzymolysis and fermentation of pigskin, comprising the following steps:

[0020] (1) Rinse the raw pigskin with clean water until the pH of the washing water used is 6.5, and then physically cut the washed pigskin to make pigskin pieces with a width of no more than 2 cm and a length of no more than 15 cm;

[0021] (2) Add pigskin fragments into the stirring tank, the volume of the added pigskin fragments is 1 / 4 of the volume of the stirring tank, add 1 / 4 tank volume of water, add protease with a specification of 50000u / g, and the amount added is 0.2% of the mass of pigskin fragments, heated to 55°C and stirred for enzymolysis, after the pigskin fragments are completely dissolved, add pigskin fragments of the same quality to continue the enzymolysis, adding four times in total to obtain a polypeptide enzymatic hydrolysis solution;

[0022] (3) Heat the polypeptide enzymatic hydrolysis solution to 70°C to inactivate the...

Embodiment 2

[0026] A method for preparing liquid organic fertilizer by enzymolysis and fermentation of pigskin, comprising the following steps:

[0027] (1) Rinse the raw pigskin with clean water until the pH of the washing water used is 7.2, and then physically cut the washed pigskin to make pigskin fragments with a width of 1 cm and a length of 10 cm;

[0028] (2) Add pigskin fragments into the stirring tank, the volume of the added pigskin fragments is 1 / 4 of the volume of the stirring tank, add 1 / 4 tank volume of water, add protease with a specification of 50000u / g, and the amount added is 2% of the mass of pigskin fragments, heated to 40°C and stirred for enzymolysis, after the pigskin fragments are completely dissolved, add pigskin fragments of the same quality to continue enzymolysis, adding four times in total to obtain polypeptide enzymatic hydrolysis solution;

[0029] (3) Heat the polypeptide enzymatic solution to 80°C to inactivate the protease, then lower the temperature to 4...

Embodiment 3

[0033] A method for preparing liquid organic fertilizer by enzymolysis and fermentation of pigskin, comprising the following steps:

[0034] (1) Rinse the raw pigskin with clean water until the pH of the washing water used is 6.5, and then physically cut the washed pigskin to make pigskin fragments with a width of no more than 1 cm and a length of no more than 15 cm;

[0035] (2) Add pigskin fragments into the stirring tank, the volume of the added pigskin fragments is 1 / 4 of the volume of the stirring tank, add 1 / 4 tank volume of water, add protease with a specification of 50000u / g, and the amount added is 5% of the mass of pigskin fragments, heated to 35°C and stirred for enzymolysis, after the pigskin fragments are completely dissolved, add pigskin fragments of the same quality to continue enzymolysis, adding four times in total to obtain a polypeptide enzymatic hydrolysis solution;

[0036] (3) Heat the polypeptide enzymatic solution to 85°C to inactivate the protease, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com