Novel low-resistance chlor-alkali industrial ion conduction membrane and preparation method thereof

An ion-conducting membrane and chlor-alkali industry technology, applied in the field of new low-resistance chlor-alkali industrial ion-conducting membrane and its preparation, can solve the problems of increased membrane resistance, increased cell pressure, etc. Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

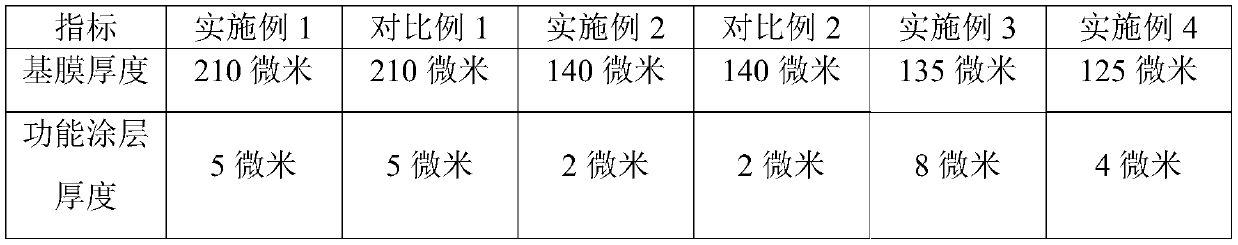

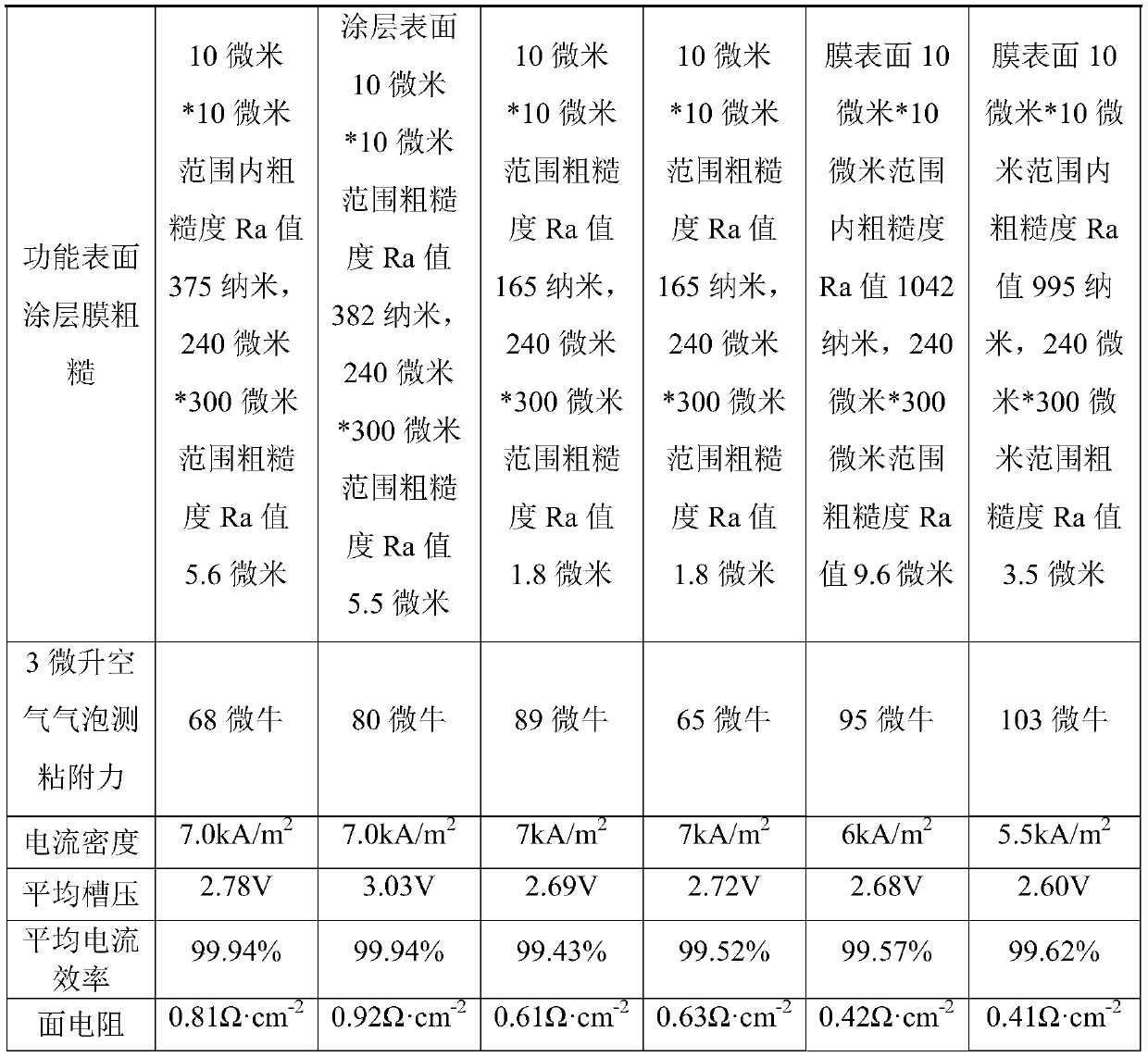

Embodiment 1

[0043] The novel low-resistance chlor-alkali industrial ion-conducting membrane shown in Example 1 consists of the first perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, perfluorocarboxylic acid polymer layer, perfluoropolymer reinforced network and functional The surface coating is composed of a surface coating; wherein, the functional surface coating is a porous rough structure composed of a perfluorinated ion polymer, and the perfluoropolymer reinforced mesh is composed of polytetrafluoroethylene and silk.

[0044] The preparation method of the novel low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 1 is prepared by the following steps:

[0045] (1) Adopt the perfluorosulfonic acid resin of IEC=1.0mmol / g and the perfluorocarboxylic acid resin of IEC=0.8mmol / g to obtain material A through melt granulation according to mass ratio 10:1, then adopt material A and IEC= 0.8mmol / g perfluorocarboxylic acid resin is m...

Embodiment 2

[0059] The novel low-resistance chlor-alkali industrial ion-conducting membrane shown in Example 2, perfluorosulfonic acid polymer layer, the second perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, perfluoropolymer reinforced net and functional surface Coating composition; Among them, the functional surface coating is a porous rough structure composed of perfluoroionic polymers, and the perfluoropolymer reinforced mesh is composed of polytetrafluoroethylene and silk.

[0060] The preparation method of the novel low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 2 is prepared by the following steps:

[0061] (1) Use IEC=1.0mmol / g perfluorosulfonic acid resin and IEC=0.8mmol / g perfluorocarboxylic acid resin to obtain material A through melt granulation at a mass ratio of 1:100, and then use material A and IEC= 1.0mmol / g perfluorosulfonic acid resin is mixed and co-extruded to form a perfluoroion exchange resin base...

Embodiment 3

[0076] The new low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 3 consists of the first perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, the second perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, It is composed of perfluoropolymer reinforced net and functional surface coating; among them, the functional surface coating is a porous rough structure composed of perfluoropolymer, and the perfluoropolymer reinforced net is composed of non-woven polymer and protein fiber. into.

[0077] The preparation method of the novel low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 3 is prepared by the following steps:

[0078](1) Use IEC=1.0mmol / g perfluorosulfonic acid resin and IEC=0.8mmol / g perfluorocarboxylic acid resin to obtain material A through melt granulation at a mass ratio of 10:1, using IEC=1.0mmol / g The perfluorosulfonic acid resin and the perflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com