AE multi-element aerogel rubber-plastic blended closed-pore secondary mold pressing foaming material and preparation method thereof

A foaming material and secondary molding technology, applied in the field of polymer materials and their preparation, can solve the problems of uneven pore size, poor, poor dispersion, etc., and achieve the effect of avoiding uneven mixing and not easy to foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

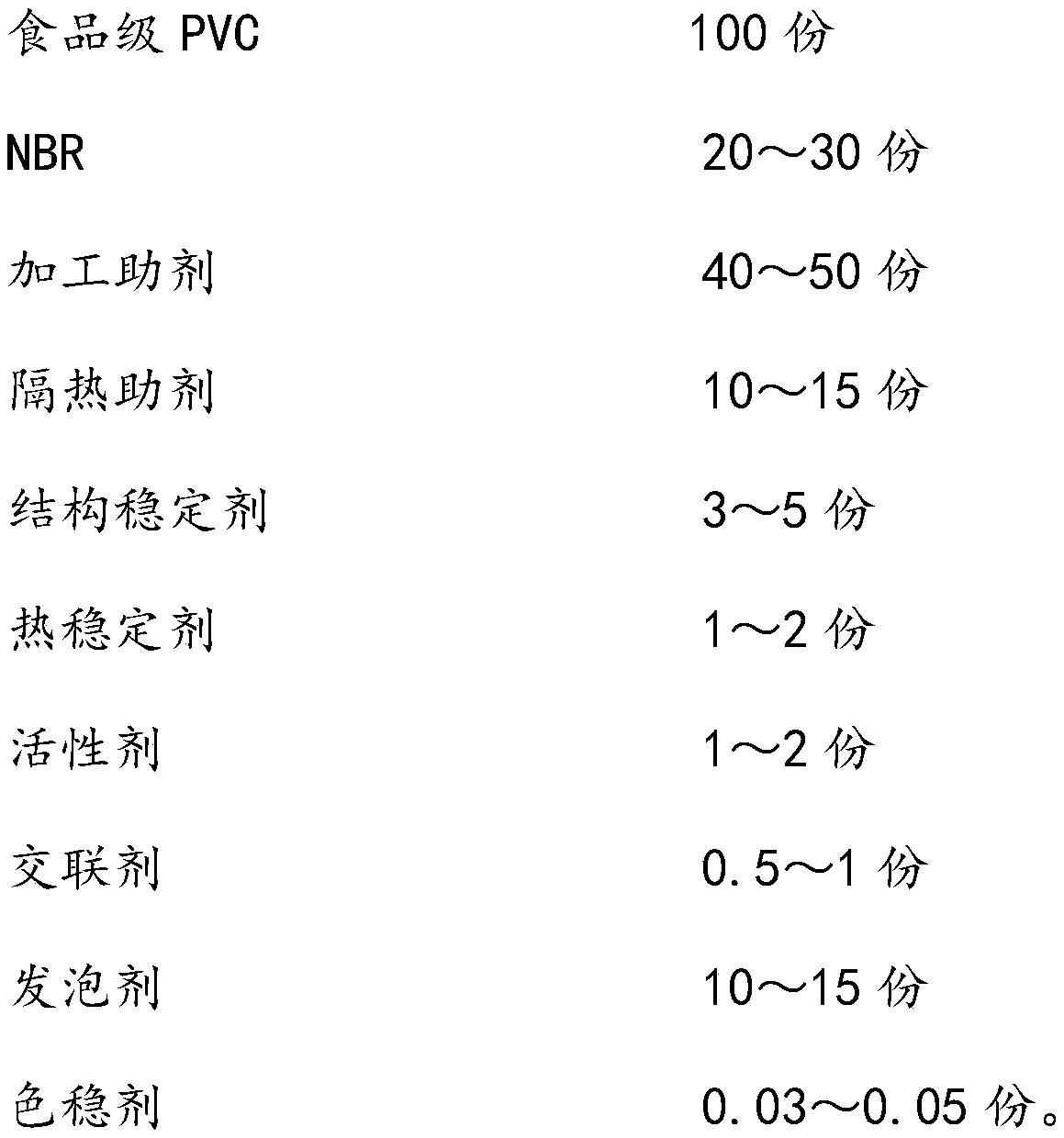

[0063] A preparation method of AE multi-component airgel rubber blended closed-cell secondary molding foaming material, comprising the following steps:

[0064] Food grade PVC premix:

[0065] According to the weight of the formula, first mix 100 parts of food grade PVC, 10 parts of heat insulation additive 409, 3 parts of structural stabilizer, 1 part of heat stabilizer, and 1 part of active agent for 18 minutes. The temperature reaches 80 After ℃, add 40 parts of processing aid (citric acid anhydrous food grade), continue to pressurize and stir until it reaches 135 ℃, and maintain it for 8 minutes;

[0066] When the rubber is mixed evenly and the temperature rises to 135°C, discharge the glue;

[0067] Open mill refining:

[0068] Put the sizing material obtained in the previous process into the open mill, and put the mixed material into the open mill, and knead for 8 minutes with a 2mm roller gap;

[0069] Calendering and standing:

[0070] The rubber material obtained ...

Embodiment 2

[0084] A preparation method of AE multi-component airgel rubber blended closed-cell secondary molding foaming material, comprising the following steps:

[0085] Food grade PVC premix:

[0086] According to the weight of the formula, 100 parts of food-grade PVC, 13 parts of heat insulation additive 409, 4 parts of structural stabilizer, 1.5 parts of heat stabilizer, and 1.5 parts of active agent are banburyed and blended for 20 minutes. The temperature reaches 80 After ℃, add 45 parts of processing aid (citric acid anhydrous food grade), continue to pressurize and stir until it reaches 140 ℃, and keep it for 10 minutes;

[0087] When the rubber is mixed evenly and the temperature rises to 140°C, remove the glue;

[0088] Open mill refining:

[0089] The sizing material obtained in the previous process is put into the open mill, and the mixed material is put into the open mill, and the 2mm roller gap is turned for 9 minutes;

[0090] Calendering and standing:

[0091] The ru...

Embodiment 3

[0105] A preparation method of AE multi-component airgel rubber blended closed-cell secondary molding foaming material, comprising the following steps:

[0106] Food grade PVC premix:

[0107] Mix 100 parts of food-grade PVC, 15 parts of thermal insulation additive 409, 5 parts of structural stabilizer, 2 parts of heat stabilizer, and 2 parts of active agent for 20 minutes and add 50 parts after the temperature reaches 80°C The processing aid (citric acid anhydrous food grade), continue pressurized stirring until reaching 140 ℃, maintain 10 minutes;

[0108] When the rubber is mixed evenly and the temperature rises to 140°C, remove the glue;

[0109] Open mill refining:

[0110] Put the sizing material obtained in the previous process into the open mill, put the mixed material into the open mill, and knead for 10 minutes with a 2mm roller gap;

[0111] Calendering and standing:

[0112] Put the sizing material obtained in the previous process into a 16-inch four-roller cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com