Electrochemical treatment method of copper foil and composite copper foil material

A treatment method and electrochemical technology, applied in the direction of electrolytic organic material coating, etc., can solve the problems of slow reaction speed, carcinogenicity, toxicity, etc., and achieve the effects of good oxidation resistance, controllable process and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

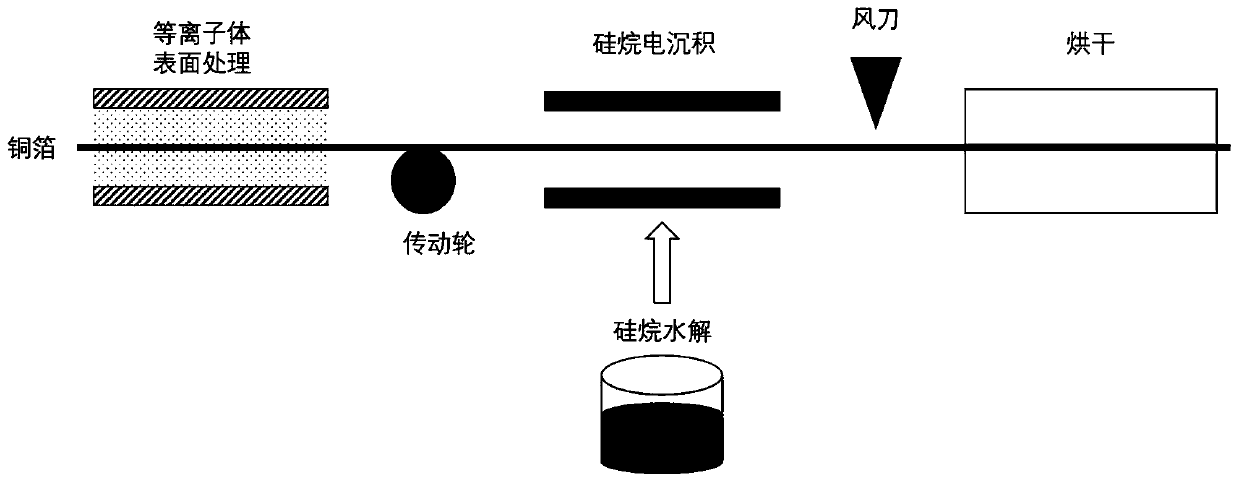

Method used

Image

Examples

Embodiment 1

[0047] Plasma surface treatment is carried out on the copper foil. The discharge method is low-voltage capacitive coupling discharge. is 10W. Mix dodecyltrimethoxysilane with sulfuric acid solution and acetic acid solution, and hydrolyze at 5°C for 48 hours, wherein the volume ratio of dodecyltrimethoxysilane to the mixed solution is 12:100; Add sodium sulfate in the solution, obtain described electrolytic solution, wherein, the acid concentration in the electrolytic solution is 0.05mol / L, and the concentration of sodium sulfate in the electrolytic solution is 0.1g / L; In the passivation tank, use above-mentioned electrolytic solution, with The metal titanium plate covered with a protective coating is used as the anode, and the electrolytic current density is 2A / m 2 , the temperature of the bath solution is 70°C, the copper foil treated with the plasma surface enters the passivation tank through the transmission device, as the cathode of the electrochemical reaction, after the...

Embodiment 2

[0050] Plasma surface treatment is carried out on the copper foil. The discharge method is low-voltage capacitive coupling discharge. It is 400W. Mix dodecyltrimethoxysilane with hydrochloric acid solution and acetic acid solution, and hydrolyze at 60°C for 1 hour, wherein the volume ratio of dodecyltrimethoxysilane to the mixed solution is 90:100; Sodium sulfate is added in the solution to obtain the electrolyte, wherein the acid concentration in the electrolyte is 2mol / L, and the concentration of sodium sulfate in the electrolyte is 15g / L; in the passivation tank, use the above electrolyte to cover the surface The metal titanium plate with protective coating is used as the anode, and the electrolytic current density is 60A / m 2 , the temperature of the bath is 20°C, and the copper foil after plasma surface treatment enters the passivation bath through the transmission device as the cathode of the electrochemical reaction. After electrochemical treatment, after the copper fo...

Embodiment 3

[0052] Plasma surface treatment is carried out on the copper foil. The discharge method is low-voltage capacitive coupling discharge. It is 240W. Mix dodecyltrimethoxysilane with nitric acid solution and acetic acid solution, and hydrolyze at 25°C for 12 hours, wherein the volume ratio of dodecyltrimethoxysilane to the mixed solution is 20:100; Sodium sulfate is added in the solution to obtain the electrolyte, wherein the acid concentration in the electrolyte is 0.5mol / L, and the concentration of sodium sulfate in the electrolyte is 7g / L; A metal titanium plate covered with a protective coating is used as the anode, and the electrolytic current density is 10A / m 2 , the bath temperature is 50°C, the copper foil after plasma surface treatment enters the passivation tank through the transmission device, as the cathode of the electrochemical reaction, after electrochemical treatment, the copper foil leaves the passivation tank through the transmission device , a layer of silane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com