Directly-implanted personalized alveolar bone-repairing prosthesis and preparation method thereof

A technology of alveolar bone and implants, applied in dental prosthesis, dental implants, dental restorations, etc., can solve the problems of low success rate of dental implants, a lot of time to recover, and great difficulty, so as to reduce the number of operations, Good binding stability, good biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

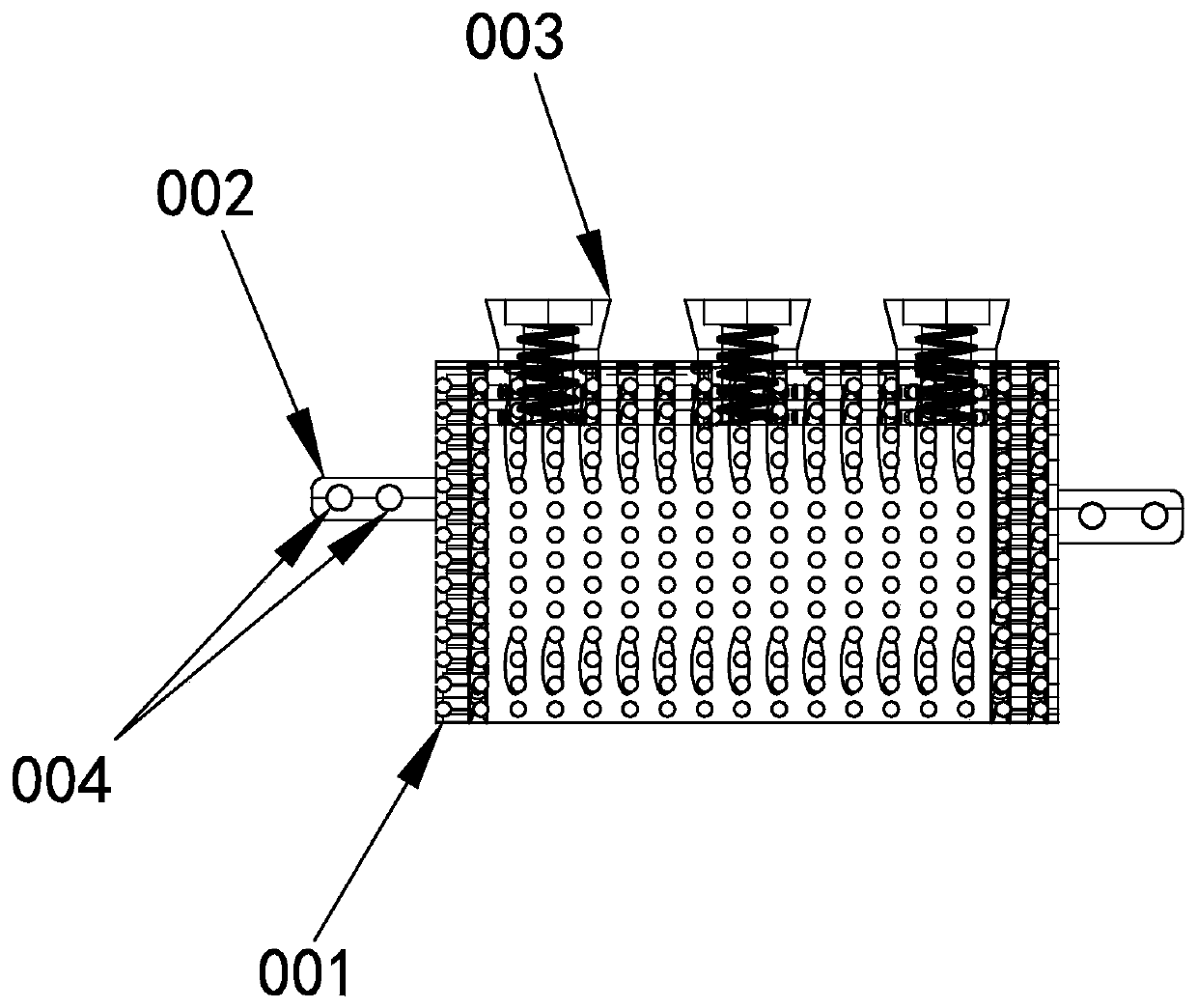

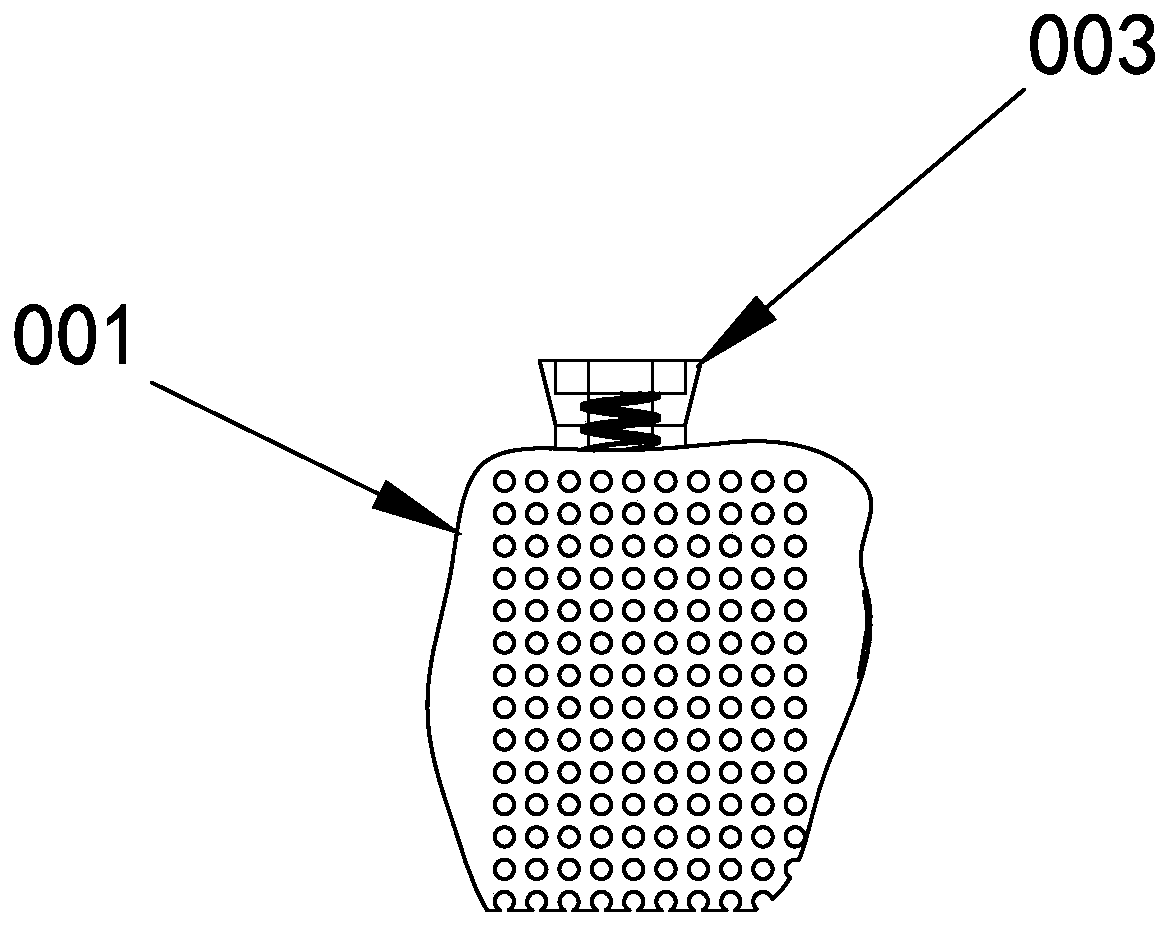

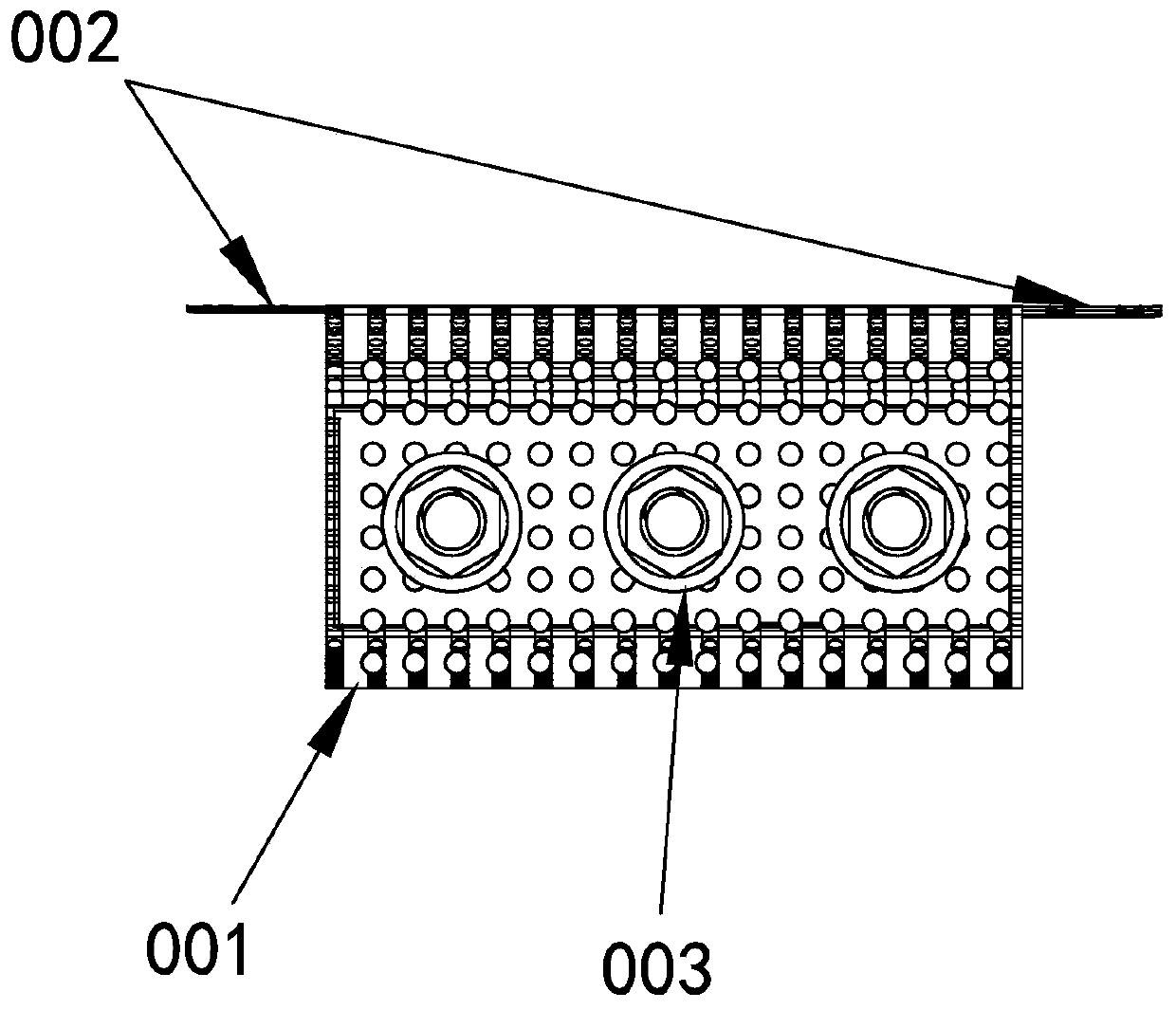

[0026] Example 1, according to the following steps to prepare a personalized alveolar bone repair prosthesis directly implanted:

[0027] 1. Obtain the required morphological data by CT scanning the patient's alveolar bone defect and surrounding bones, and then import the data into MIMICS software to generate an alveolar bone model in STL format, and then repair it.

[0028] 2. Import the patient's alveolar bone model with the defective part into the Magics software, and repair the defect through the stretching function.

[0029] 3. Import the alveolar bone model in step 2 into the Magics software, and obtain a three-dimensional filling body model that matches the alveolar bone defect through the Boolean operation function.

[0030] 4. Determine the implant installation end surface of the filling body 3D model, as well as the position and number of implant abutments on the implant installation end surface, and then remove the filling inside the filling body 3D model through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com