Preparation method of chemically grafted and modified biomass adsorbent

A technology of biomass adsorbent and chemical grafting, which is applied in the direction of chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of weak adsorption capacity of metal ions, etc., and achieve the problem of easy oxidation, high stability, no easy to be effected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

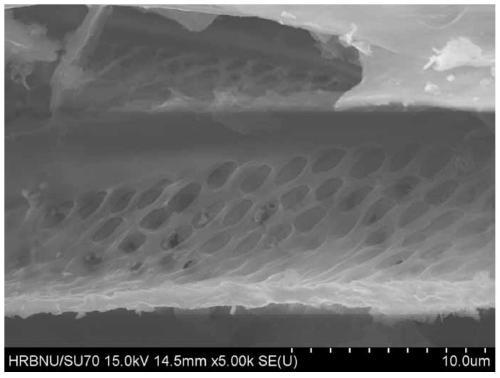

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the preparation method of the chemically grafted and modified biomass adsorbent of this embodiment is implemented according to the following steps:

[0017] 1. The biomass material is pyrolyzed at 350°C to 600°C by oxygen-limited heating carbonization method to obtain a biochar adsorbent, and after natural cooling, the biochar adsorbent is pulverized to obtain carbonized biomass;

[0018] 2. Add the carbonized biomass to the chloroform solution of pyridine, add 4-bromobutyryl chloride dropwise, seal the reaction mixture, filter it after oscillating for 10h-16h, rinse with chloroform, and obtain the washed biomass;

[0019] 3. Mix polyethyleneimine, KOH and tert-amyl alcohol to obtain a mixed modified solution, immerse the washed biomass in the mixed modified solution, shake and react at a temperature of 70-80°C, wash and dry Finally, a chemically grafted modified biomass adsorbent is obtained.

[0020] In this embodiment, the physical or chemi...

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the oxygen-limited heating carbonization method described in step 1 is to raise the temperature to 350° C. to 350° C. At 600°C, the biomass material is pyrolyzed.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the biomass material described in Step 1 is fungus chaff, corn stalks, rice husk or hemp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com