Organic-inorganic hybrid high-temperature-resistant basalt fiber impregnating compound and preparation method thereof

A technology of basalt fiber and high temperature resistance, applied in the field of sizing agent, can solve the problems of losing sizing agent, hindering the advantages of high temperature performance of basalt fiber, poor temperature resistance, etc., and achieving the effect of inhibiting cracking and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

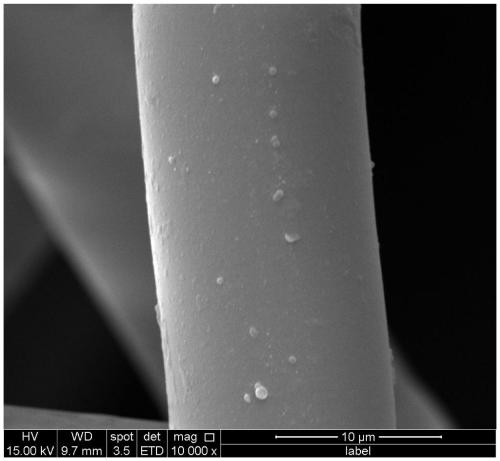

Image

Examples

Embodiment 1

[0022] This example provides an organic-inorganic hybrid heat-resistant basalt fiber sizing agent, which is made of the following components and corresponding mass percentages:

[0023] Hydroxyl-terminated silicone oil and hydrogen-containing silicone oil (the stoichiometric ratio of hydroxyl and hydrogen atoms is 1:1): 10%;

[0024] Ethyl orthosilicate: 1%;

[0025] Tartaric acid: 0.02%;

[0026] Ethanol: 1%;

[0027] Fumed silica: 4%;

[0029] Zinc phosphate powder: 3%;

[0030] Coupling agent KH550: 1%;

[0031] Sodium bentonite: 0.2%;

[0032] Water: balance.

[0033]The preparation method of the organic-inorganic hybrid heat-resistant basalt fiber sizing agent is as follows: according to the formula, first dissolve ethyl orthosilicate and tartaric acid in ethanol, and prepare component A for later use; then add hydroxyl-terminated silicone oil and hydrogen-containing silicone oil to pH In the mixed solution of acetic acid and water with a...

Embodiment 2

[0037] This example provides an organic-inorganic hybrid heat-resistant basalt fiber sizing agent, which is made of the following components and corresponding mass percentages:

[0038] Hydroxyl silicone oil and hydrogen-containing silicone oil (the stoichiometric ratio of hydroxyl and hydrogen atoms is 1:1): 2%;

[0039] Ethyl orthosilicate: 0.2%;

[0040] Dibutyltin dilaurate: 0.004%;

[0041] Isopropanol: 0.2%;

[0042] Fumed silica: 0.5%;

[0044] Zinc phosphate powder: 0.5%;

[0045] Coupling agent KH550: 0.5%;

[0046] Sodium bentonite: 0.1%;

[0047] Water: balance.

[0048] The preparation method of the organic-inorganic hybrid heat-resistant basalt fiber sizing agent is as follows: according to the formula, first dissolve ethyl orthosilicate and dibutyltin dilaurate in isopropanol, and prepare component A for later use; then mix hydroxyl silicone oil and Add hydrogen-containing silicone oil into the mixed solution of acetic acid and...

Embodiment 3

[0051] This example provides an organic-inorganic hybrid heat-resistant basalt fiber sizing agent, which is made of the following components and corresponding mass percentages:

[0052] Hydroxyl silicone oil and hydrogen-containing silicone oil (the stoichiometric ratio of hydroxyl and hydrogen atoms is 1:1): 3%;

[0053] Ethyl orthosilicate: 0.3%;

[0054] Tartaric acid: 0.006%;

[0055] Butanol: 0.3%;

[0056] Fumed silica: 2%;

[0057] Mica powder: 2%;

[0058] Zinc phosphate powder: 2%;

[0059] Coupling agent KH550: 1%;

[0060] Sodium bentonite: 0.2%;

[0061] Water: balance.

[0062] The preparation method of the organic-inorganic hybrid heat-resistant basalt fiber sizing agent is as follows: according to the formula, first dissolve ethyl orthosilicate and tartaric acid in n-butanol, and prepare component A for later use; then add hydroxyl silicone oil and hydrogen silicone oil In the mixed solution of acetic acid and water with a pH of 6, stir and emulsify at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com