Construction waste recycled composite admixture based geopolymer concrete

A construction waste and composite admixture technology, which is applied in the field of construction waste recycled composite admixture base polymer concrete, can solve the problem that the reuse rate is less than 5%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] In this embodiment, a kind of construction waste recycled composite admixture base polymer concrete comprises 184-368 parts of fly ash, 92-276 parts of recycled composite admixture, 1200 parts of coarse aggregate, 540 parts of fine aggregate, and 133.4 parts of silicon Sodium acid

[0051] (1) Raw material pretreatment:

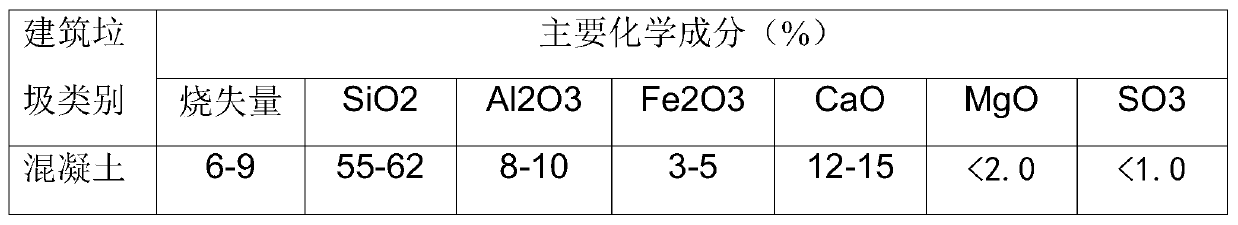

[0052] (1) Construction waste pretreatment: crush construction waste, remove iron and screen to obtain construction waste particles with a diameter of 20-50mm; among them, construction waste is divided into concrete, sintered bricks and tiles, and decoration slag. In this embodiment, the crushing and impurity removal process is carried out on the construction waste, and the construction slag particles with a particle size of 20-50 mm are transported to the silo for storage through a homogenizing distributor for use.

[0053] (2) Pretreatment of electric furnace steel slag: Extract the original electric furnace steel slag obtained by electric furnace s...

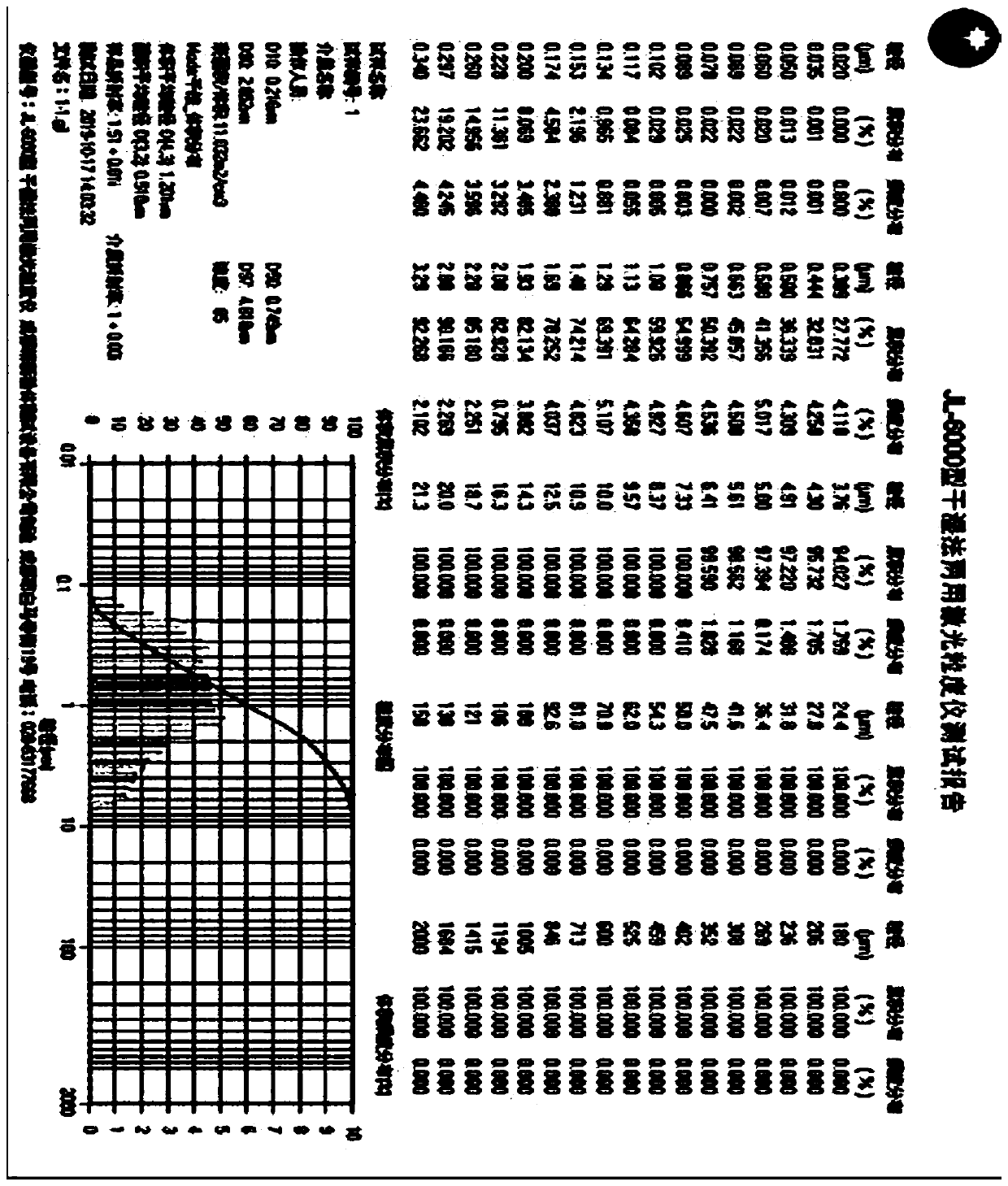

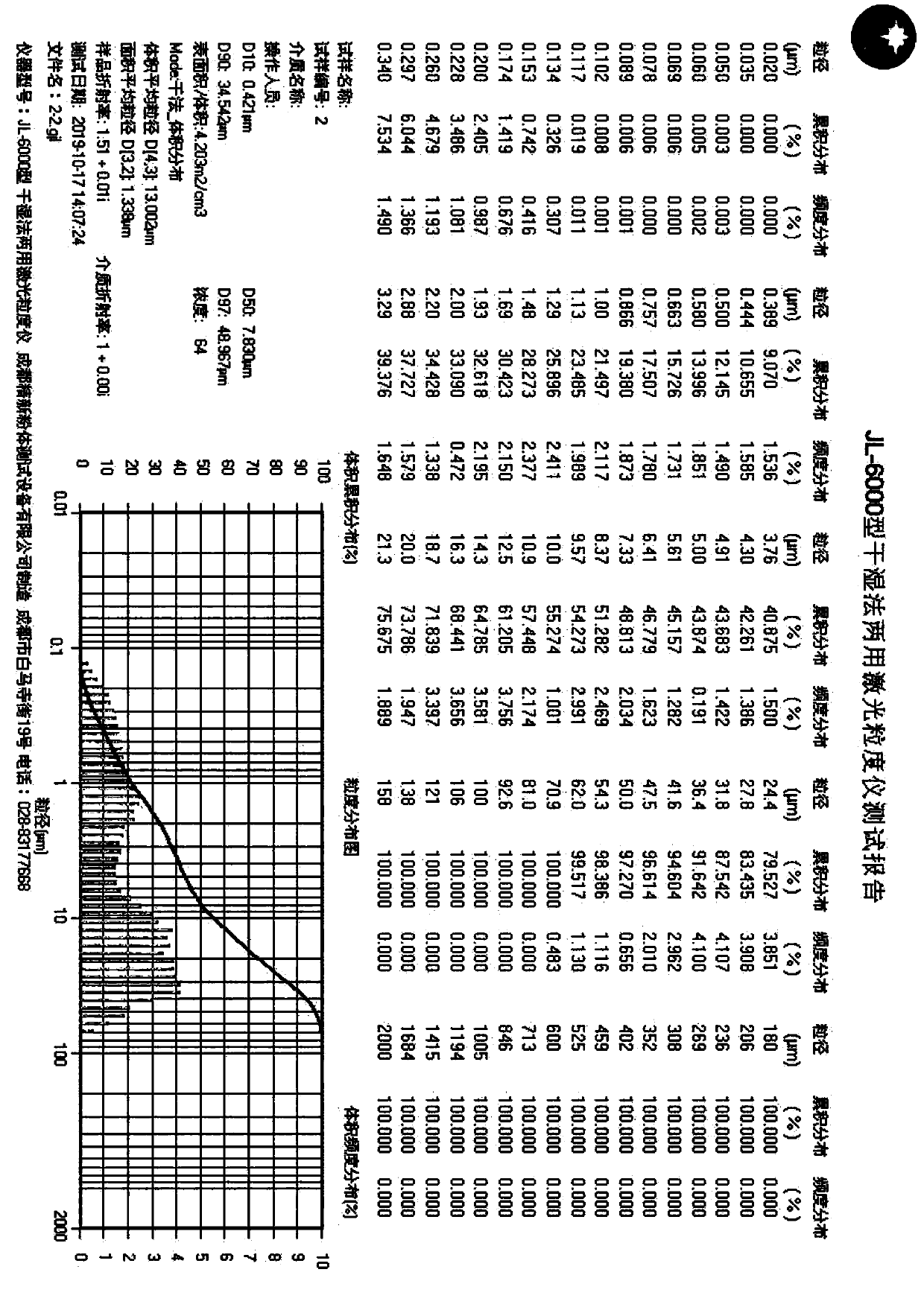

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com