Lead-free bismuth ferrite-based ceramic material and preparation method thereof

A lead-free bismuth ferrite-based, ceramic material technology, applied in the field of dielectric materials, can solve the problems of low energy storage density and energy storage efficiency, low breakdown electric field strength, etc., achieve high energy storage density and energy storage efficiency, improve Breakdown electric field strength, the effect of reducing remanent polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

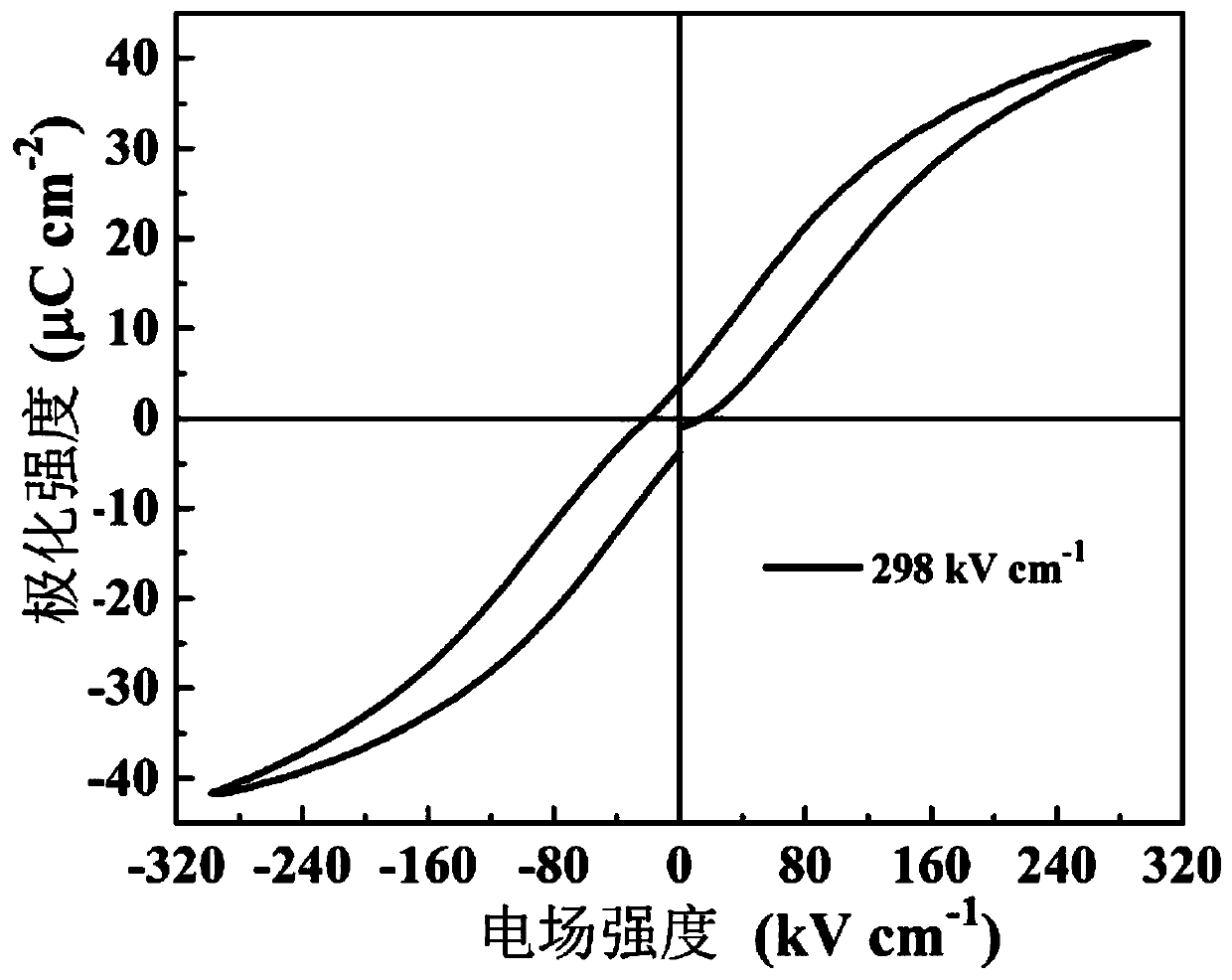

Embodiment 1

[0043] A lead-free bismuth ferrite-based ceramic with high energy storage density and energy storage efficiency, the chemical composition of the ceramic is (1-x)(0.67BiFeO 3 -0.33BaTiO 3 )-xNa 0.73 Bi 0.09 NbO 3 +0.1wt%Mn 3 o 4 , where x=0.06.

[0044] The concrete preparation steps of this ceramic material are as follows:

[0045] (1) Select Bi with a purity greater than 98% 2 o 3 , Fe 2 o 3 、BaCO 3 、TiO 2 、Na 2 CO 3 , Nb 2 o 5 and Mn 3 o 4 As a raw material for bismuth ferrite-based lead-free ceramic dielectric materials with high energy storage density and energy storage efficiency;

[0046] (2) According to the chemical formula (1-x) (0.67BiFeO 3 -0.33BaTiO 3 )-xNa 0.73 Bi 0.09 NbO 3 (Wherein x=0.06) Weigh the raw material, and make it mix homogeneously through a ball milling process, obtain the initial raw material powder; Wherein when ball milling, adopt dehydrated alcohol and ZrO 2 balls as the milling medium, ZrO 2 The mass ratio of balls to ra...

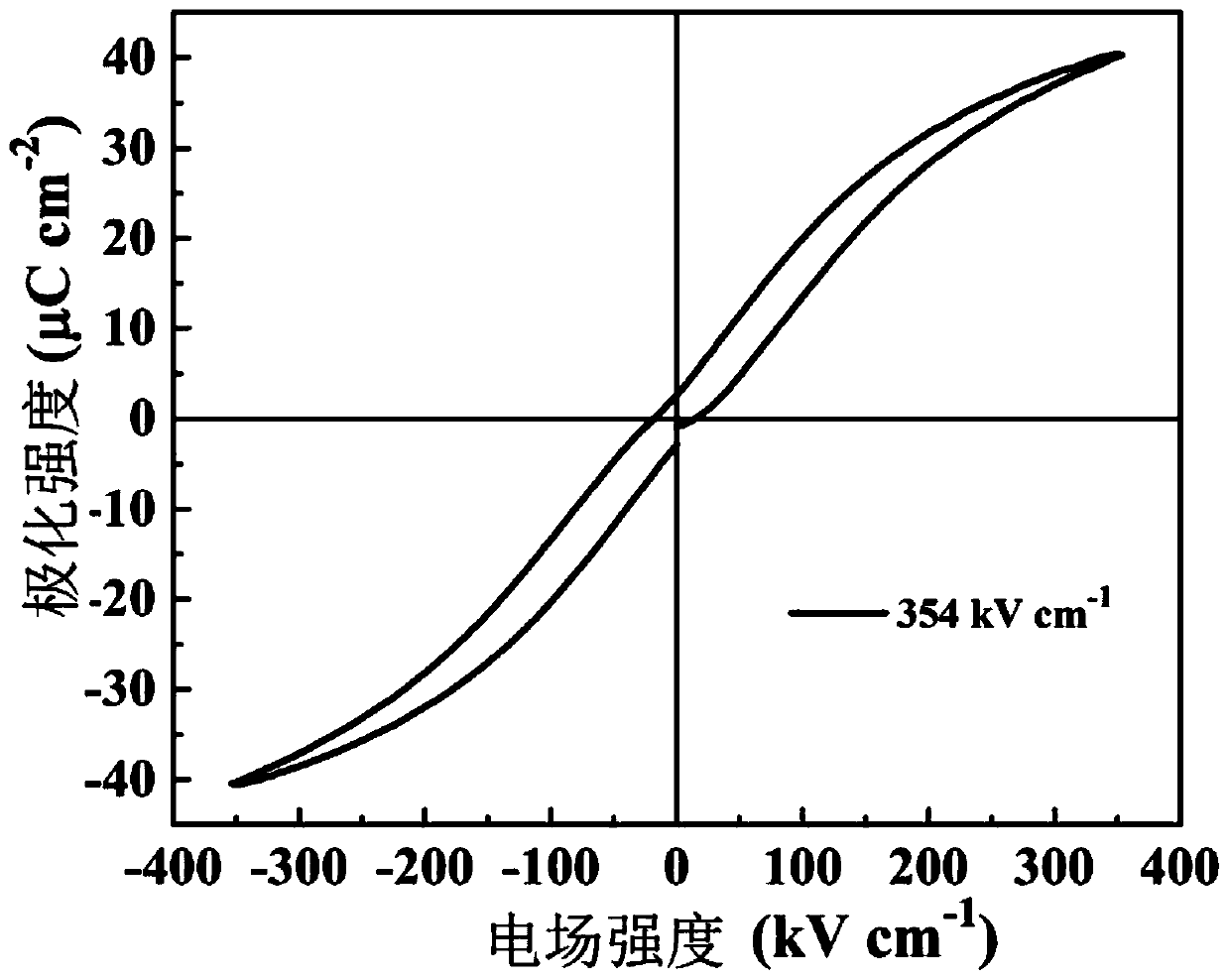

Embodiment 2

[0055] A lead-free bismuth ferrite-based ceramic with high energy storage density and energy storage efficiency, the chemical composition of the ceramic is (1-x)(0.67BiFeO 3 -0.33BaTiO 3 )-xNa 0.73 Bi 0.09 NbO 3 +0.1wt%Mn 3 o 4 , where x=0.08. Concrete preparation steps are as follows:

[0056] (1) Select Bi with a purity greater than 98% 2 o 3 , Fe 2 o 3 、BaCO 3 、TiO 2 、Na 2 CO 3 , Nb 2 o 5 and Mn 3 o 4 As a raw material for bismuth ferrite-based lead-free ceramic dielectric materials with high energy storage density and energy storage efficiency;

[0057] (2) According to the chemical formula (1-x) (0.67BiFeO 3 -0.33BaTiO 3 )-xNa 0.73 Bi 0.09 NbO 3 (wherein x=0.08) take the raw material, and make it mix uniformly through a ball milling process to obtain the initial raw material powder; wherein absolute ethanol and ZrO are used during ball milling 2 balls as the milling medium, ZrO 2 The mass ratio of balls to raw materials is 2:1, the mass ratio of a...

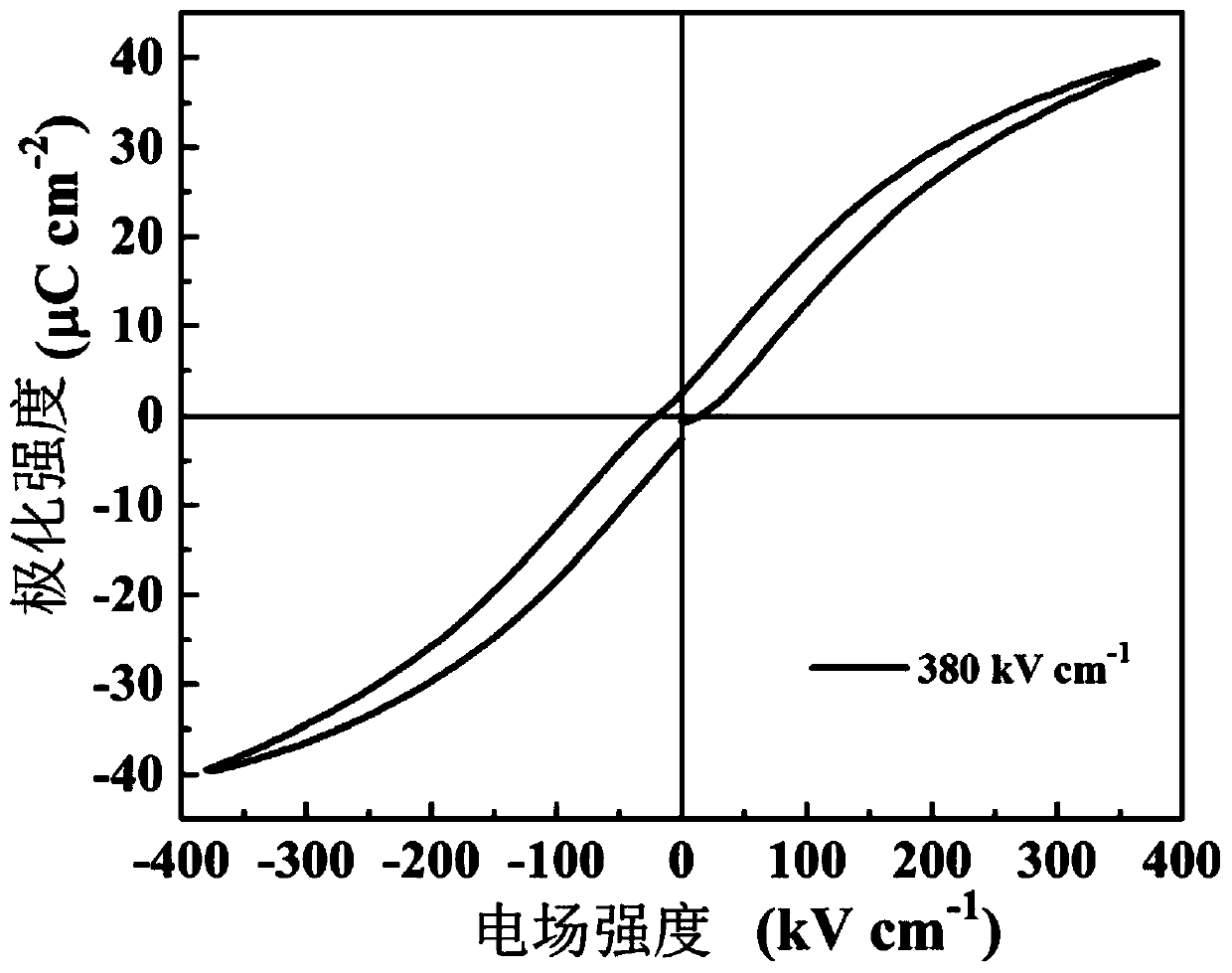

Embodiment 3

[0066] A lead-free bismuth ferrite-based ceramic with high energy storage density and energy storage efficiency, the chemical composition of the ceramic is (1-x)(0.67BiFeO 3 -0.33BaTiO 3 )-xNa 0.73 Bi 0.09 NbO 3 +0.1wt%Mn 3 o 4 , where x=0.10. Concrete preparation steps are as follows:

[0067] (1) Select Bi with a purity greater than 98% 2 o 3 , Fe 2 o 3 、BaCO 3 、TiO 2 、Na 2 CO 3 , Nb 2 o 5 and Mn 3 o 4 As a raw material for bismuth ferrite-based lead-free ceramic dielectric materials with high energy storage density and energy storage efficiency;

[0068] (2) According to the chemical formula (1-x) (0.67BiFeO 3 -0.33BaTiO 3 )-xNa 0.73 Bi 0.09 NbO 3 (Wherein x=0.10) Weigh the raw material, and make it mix uniformly through a ball milling process to obtain the initial raw material powder; wherein absolute ethanol and ZrO are used during ball milling 2 balls as the milling medium, ZrO 2 The mass ratio of balls to raw materials is 2.0:1, the mass ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com