Spray granulation method and preparation method of microwave medium powder

A technology of spray granulation and microwave medium, which is used in the preparation of microwave medium materials and the field of spray granulation of microwave medium powder, can solve the problems of high molding pressure, easy cracking during pressing, poor fluidity of microwave medium powder, etc. The effect of forming performance, eliminating green body cracking, and improving flowability and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

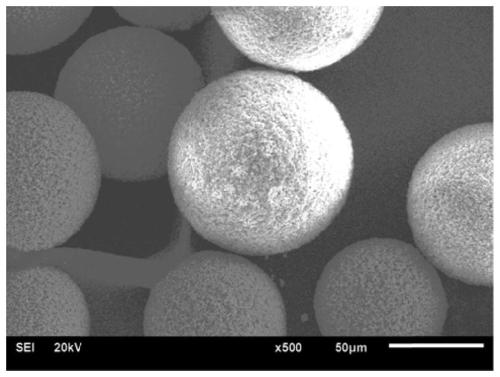

Image

Examples

Embodiment 1

[0033] The preparation method of the microwave dielectric material described in this embodiment comprises the following steps:

[0034] (1) with CaAlO 4 Based on microwave dielectric material as an example, take CaAlO 4 Adding modified additives to the raw materials of the components for mixing to obtain a mixture, adding water accounting for 60% of the amount of the mixture and 0.5wt% dispersant for mixing, and putting them into a ball mill for ball milling for 3 hours;

[0035] (2) Put the dispersed mixture into the sand mill, use zirconium balls as the grinding medium, grind for 3-8 times, control the solid content of the slurry after grinding between 60%-65%, and obtain the required raw materials slurry;

[0036] (3) Get PEG20000 glue, PVA glue and polyacrylic acid glue, add water respectively and fully dissolve through heating, respectively make PEG glue, PVA glue and polyacrylic acid glue, set aside;

[0037] In the raw material slurry of step (2) gained, add above-me...

Embodiment 2

[0042] The preparation method of the microwave dielectric material described in this embodiment comprises the following steps:

[0043] (1) with CaAlO 4 Based on microwave dielectric material as an example, take CaAlO 4 Adding modified additives to the raw materials of the components for mixing to obtain a mixture, adding water accounting for 60 wt% of the mixture and 0.5 wt% dispersant for mixing, and putting them into a ball mill for ball milling for 3 hours;

[0044] (2) Put the dispersed mixture into the sand mill, use zirconium balls as the grinding medium, grind for 3-8 times, control the solid content of the slurry after grinding between 60%-65%, and obtain the required raw materials slurry;

[0045] (3) Get PEG20000 glue, PVA glue and polyacrylic acid glue, add water respectively and fully dissolve through heating, respectively make PEG glue, PVA glue and polyacrylic acid glue, set aside;

[0046] In the raw material slurry of step (2) gained, add above-mentioned PE...

Embodiment 3

[0051] The preparation method of the microwave dielectric material described in this embodiment comprises the following steps:

[0052] (1) with CaAlO 4 Based on microwave dielectric material as an example, take CaAlO 4 Add modified additives to the raw materials of the components for mixing, and add 60wt% of water and 0.5wt% of dispersant for mixing, and put them into a ball mill for ball milling for 3 hours;

[0053] (2) Put the dispersed mixture into the sand mill, use zirconium balls as the grinding medium, grind for 3-8 times, control the solid content of the slurry after grinding between 60%-65%, and obtain the required raw materials slurry;

[0054] (3) Get PEG20000 glue, PVA glue and polyacrylic acid glue, add water respectively and fully dissolve through heating, respectively make PEG glue, PVA glue and polyacrylic acid glue, set aside;

[0055] In the raw material slurry of step (2) gained, add above-mentioned PEG glue, PVA glue and polyacrylic acid glue successiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com