Electric heating self-repairing polyurethane elastomer and preparation method thereof

A technology of polyurethane elastomer and polyurethane prepolymer, which is applied in the field of polymer materials and achieves the effects of wide application prospects, simple structure and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the dihydric alcohol chain extender containing acylhydrazone bond according to the present invention comprises the following steps: dissolving 15-30 parts by weight of hydroxy carbonyl compound in an organic solvent, dissolving 10-20 parts by weight of diacyl The hydrazine compound is dissolved in deionized water, mixed, and reacted at 20°C-60°C for 2 to 4 hours to obtain a dihydric alcohol chain extender containing an acylhydrazone bond; wherein, the organic solvent is dimethyl sulfoxide, N, N-dimethylformamide, isopropanol, acetone, absolute ethanol or ethyl acetate, the sum of the parts by weight of the deionized water and the organic solvent is 120-140 parts.

[0034] The dihydrazide compound is malonic acid dihydrazide, pimelic acid hydrazide, suberic dihydrazide, pentanedihydrazide, sebacic acid dihydrazide, dodecanedicarboxylic acid dihydrazide, p-phenylene Any one or a mixture of dicarboxylic acid dihydrazide, phthalic acid dihydrazide,...

Embodiment 11

[0039] Example 1.1: Preparation of succinic acid dihydrazone diol chain extender

[0040] Get p-Hydroxybenzaldehyde 8.9g (0.08mol-CHO) and dissolve in 48.8g absolute ethanol, get succinic acid dihydrazide 7.52g (hydrazide group 0.08mol) and dissolve in 87.0g deionized water; Both mix The solution was mixed evenly and reacted at 45° C. for 3 h under stirring at 250 rpm. Filtration under reduced pressure, the resulting product is washed successively with 150g ethanol (3 times, each 50g) at room temperature, and after drying, obtain a dibasic alcohol containing an acylhydrazone bond, which is p-Hydroxybenzaldehyde succinic acid diformylhydrazone . The product is a white solid powder. Productive rate 86%, the molecular structural formula of the product obtained is as follows:

[0041]

Embodiment 12

[0042] Example 1.2: Preparation of succinic acid dihydrazone diol chain extender

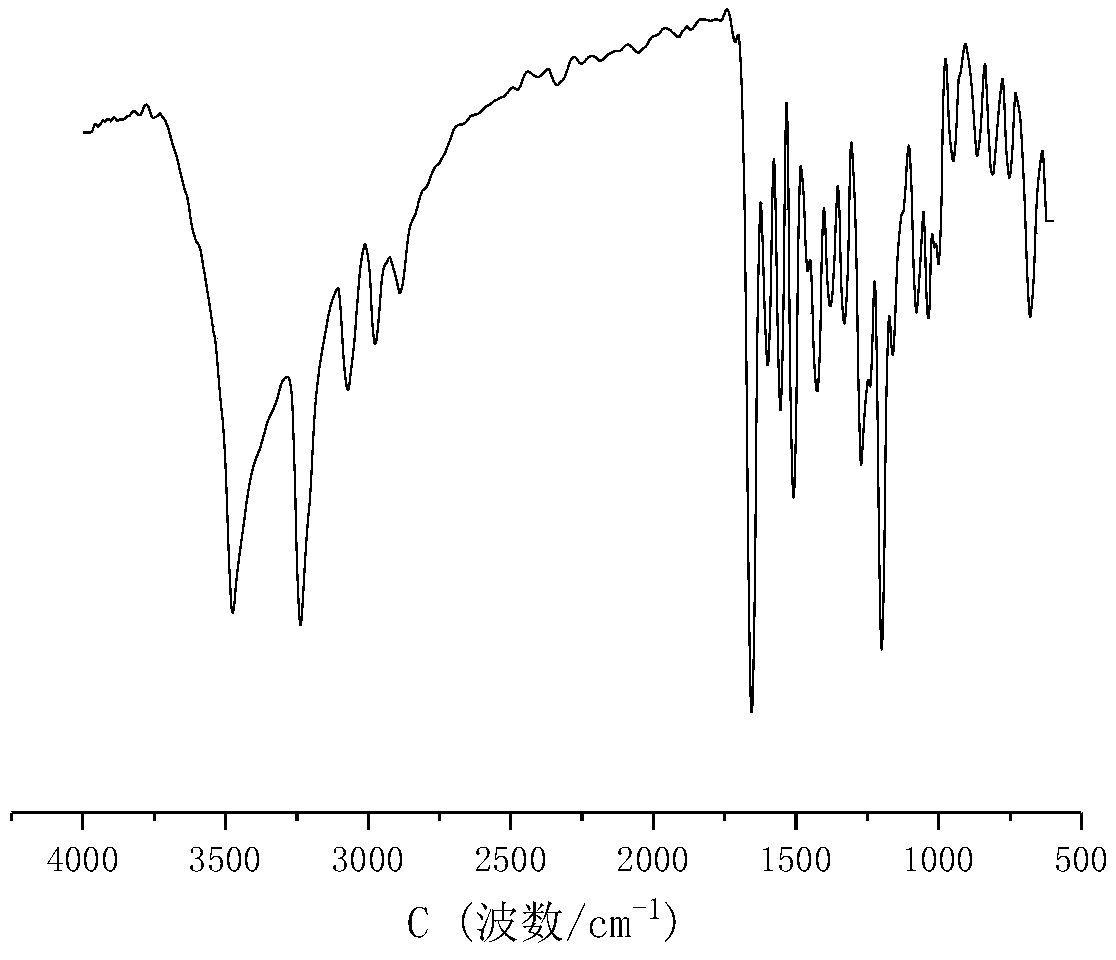

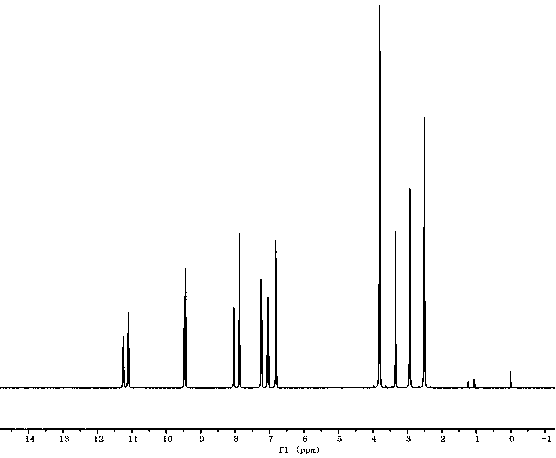

[0043] Dissolve 12.16g of vanillin (0.08mol-CHO) in 48.8g of absolute ethanol, and dissolve 7.52g of succinic acid dihydrazide (0.08mol of hydrazide group) in 87.0g of deionized water; mix the mixture After uniformity, react at 35°C for 2h under stirring at 250rpm. Filtrate under reduced pressure, and the obtained product is washed successively with 150 g of ethanol (3 times, 50 g each) at room temperature, and dried to obtain a dihydric alcohol containing an acylhydrazone bond, which is vanillin succinic acid diformylhydrazone. The infrared spectrum of vanillin succinic acid diformylhydrazone is shown in figure 1 , see the NMR spectrum figure 2 ; The product is a white solid powder. Productive rate 96%, the molecular structural formula of the product obtained is as follows:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com