Heat stabilizer and composite material containing same

A heat stabilizer and composite material technology, applied in the field of heat stabilizer and composite materials, can solve problems such as poor dispersion, high price, mold corrosion, etc.

Active Publication Date: 2020-05-29

BENSONG ENG PLASTICS HANGZHOU

View PDF9 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] 150°C, especially 170°C, 190°C, or even 210°C, polyol heat stabilizers and iron powder heat stabilizers are often used in the industry, but the shortcomings of the two are obvious and cannot be overcome

The polyol heat stabilizer will have obvious white precipitation in high temperature and high humidity environment, resulting in the formation of white frost on the surface of the product, which not only greatly affects the appearance, but also seriously reduces the heat resistance of the product due to the precipitation of the heat stabilizer

Iron powder heat stabilizer has poor dispersion in some specific resin systems, such as nylon system; it seriously affects the initial mechanical properties of the material; it has a great negative impact on the electrical properties of the material, especially the CTI value; long-term use is easy to damage the mold Causes severe corrosion; expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0063]

[0064]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

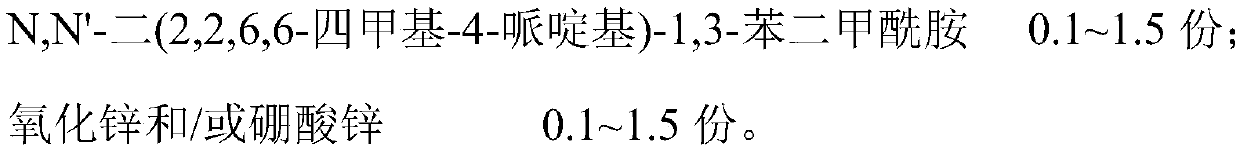

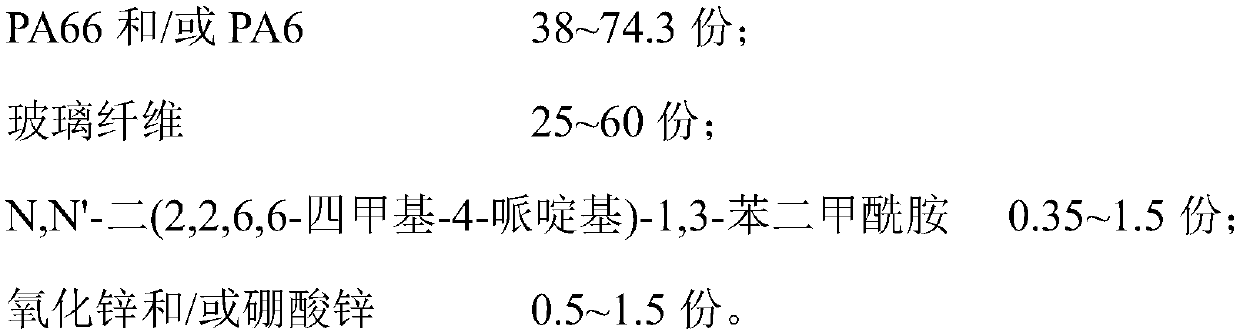

The invention belongs to the technical field of polymer modification, and provides a heat stabilizer. The heat stabilizer is composed of N,N'-bis(2,2,6,6-tetramethyl-4-piperidyl)-1,3-benzenedicarboxamide and a zinc compound, wherein the zinc compound is selected from any one or a mixture of more of zinc carboxylate, zinc carbonate, zinc titanate, zinc molybdate, zinc ferrite, zinc sulfate, zinc phosphate, zinc oxide, zinc borate and zinc halide. Compared with the prior art, the heat stabilizer provided by the invention has the advantages that a resin base material is endowed with good long-term heat resistance; the heat stabilizer has better dispersity in resin; the fiber floating condition of the surface of the glass fiber reinforced injection molding part is improved; long-term injectionmolding does not corrode the mold; and the CTI value (relative tracking index) of the product is not influenced.

Description

technical field [0001] The invention belongs to the technical field of polymer modification, and relates to a heat stabilizer and a composite material containing the heat stabilizer. Background technique [0002] In the past, in the field of polymer modification technology, especially for the research on the heat resistance of composite materials, the existing technology provides a variety of heat-resistant additives for selection. For example, the book "Plastic Additives Handbook" edited by Swiss Hans Zweifel introduces phenolic heat stabilizers, phenol-sulfur synergistic heat stabilizers, phosphite heat stabilizers, copper salt heat stabilizers, copper iodine heat stabilizers Chemical synergistic heat stabilizers, aromatic amine heat stabilizers, polyol heat stabilizers, and sterically hindered amine heat stabilizers, etc., and the effects and limitations of each heat-resistant adjuvant are discussed using specific experiments. [0003] The research on the heat resistance...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L77/06C08K5/3435C08K7/14C08K3/22C08K13/04

CPCC08K5/3435C08K7/14C08K3/22C08K13/04C08K2003/2296C08K2201/003C08L2201/08C08L77/06

Inventor 于同周昌伟叶巍陈剑锐

Owner BENSONG ENG PLASTICS HANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com