Manufacturing method of integrally-formed inductor and integrally-formed inductor

A production method and inductor technology, applied in transformer/inductor parts, inductor/transformer/magnet manufacturing, transformer/inductor noise damping, etc., can solve the problems of polluting the environment, high processing costs, component gaps, etc., to achieve Good fluidity and compactability, good effect, excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

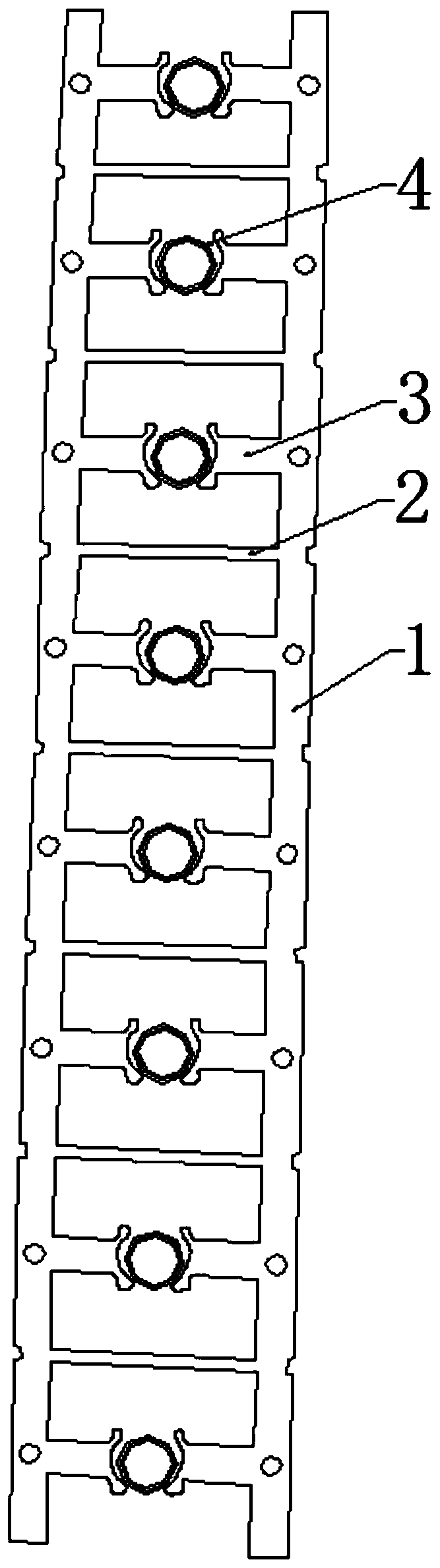

Image

Examples

Embodiment 1

[0036] A method for manufacturing an integrally formed inductor, comprising:

[0037] Step 1, making the coil blank according to the set requirements;

[0038] Step 2, making fine spherical metal powder;

[0039] The preparation method of the fine spherical metal powder is to mix the hydroxyl powder, epoxy resin, zinc stearate and acetone uniformly according to the weight ratio of 100:5:2:3, and then keep the temperature at 80°C for 1 hour, Then crush and grind to check whether the prepared powder satisfies the sphericity ≥ 90%, and whether the powder particle size meets: D50≤15μm, D90≤30μm; epoxy resin is used as a binder, and zinc stearate is added as a lubricant; hydroxyl The powder is hydroxyl iron powder, and the epoxy resin is the polycondensation product of epichlorohydrin and bisphenol A.

[0040] If satisfied, the preparation of fine spherical metal powder is completed;

[0041] If it is not satisfied, then mix the prepared powder with epoxy resin, zinc stearate an...

Embodiment 2

[0047] A method for manufacturing an integrally formed inductor, comprising:

[0048] Step 1, making the coil blank according to the set requirements;

[0049] Step 2, making fine spherical metal powder;

[0050] The preparation method of the fine spherical metal powder is as follows: mix the hydroxyl powder with epoxy resin, zinc stearate and acetone according to the weight ratio of 100:20:15:10, and then keep the temperature at 90°C for 2 hours, Then crush and grind to check whether the prepared powder satisfies the sphericity ≥ 90%, and whether the powder particle size meets: D50≤15μm, D90≤30μm; epoxy resin is used as a binder, and zinc stearate is added as a lubricant; hydroxyl The powder is hydroxyl iron powder, and the epoxy resin is the polycondensation product of epichlorohydrin and bisphenol A.

[0051] If satisfied, the preparation of fine spherical metal powder is completed;

[0052] If it is not satisfied, then mix the prepared powder with epoxy resin, zinc stea...

Embodiment 3

[0056] A method for manufacturing an integrally formed inductor, comprising:

[0057] Step 1, making the coil blank according to the set requirements;

[0058] Step 2, making fine spherical metal powder;

[0059]The preparation method of the fine spherical metal powder is as follows: mix the hydroxyl powder with epoxy resin, zinc stearate and acetone according to the weight ratio of 100:15.26:8.65:5.26, and then keep the temperature at 86.6°C for 1.6 hours. Then crush and grind to check whether the prepared powder satisfies the sphericity ≥ 90%, and whether the powder particle size meets: D50≤15μm, D90≤30μm; epoxy resin is used as a binder, and zinc stearate is added as a lubricant; hydroxyl The powder is hydroxyl iron powder, and the epoxy resin is the polycondensation product of epichlorohydrin and bisphenol A.

[0060] If satisfied, the preparation of fine spherical metal powder is completed;

[0061] If it is not satisfied, then mix the prepared powder with epoxy resin,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com