Composition and its application in preparation of enzymatic cream and fermented enzymatic cream

A technique for cream and composition, applied in the field of dairy products, can solve the problem of no fermented enzymatic hydrolysis of cream, etc., and achieves improvement of antioxidant property and/or emulsion stability, improvement of tissue state and taste, and improvement of sensory evaluation quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

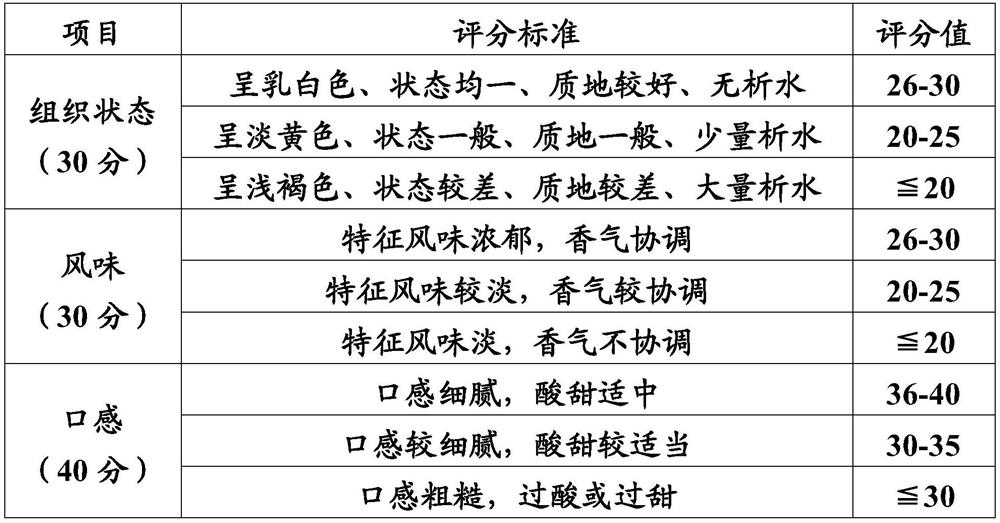

Examples

Embodiment 1

[0088] Example 1 Preparation of Enzymatic Hydrolysis Cream 1 and Fermentation Enzyme Hydrolysis Cream 1

[0089] (1) separating the qualified milk of the index by a cream separator to obtain whipped cream;

[0090] (2) Sodium caseinate, whey protein powder and Palatase 20000L lipase are added to the cream and mixed to obtain a mixture, wherein the addition weight of sodium caseinate is 0.15% of the weight of the cream, and the addition of whey protein powder The weight is 0.6% of the weight of the cream, and the added weight of Palatase20000L lipase is 0.4‰ of the weight of the cream; the mixture is incubated at 45 ° C for 6 hours to obtain an enzymatic hydrolysis product; the enzymatic hydrolysis product is pasteurized (enzyme inactivation) , homogenized to obtain about 940 g of enzymatic hydrolyzed cream 1;

[0091] (3) adding 60 g of white granulated sugar to the enzymatic hydrolysis cream 1 obtained in step (2), and stirring the mixture for 15 to 20 minutes at 55°C to 60...

Embodiment 2

[0095] Example 2 Preparation of Enzymolysis Cream 2 and Fermentation Enzymolysis Cream 2

[0096] (1) separating the qualified milk of the index by a cream separator to obtain whipped cream;

[0097] (2) Sodium caseinate, whey protein powder and Palatase 20000L lipase are added to the cream and mixed to obtain a mixture, wherein the addition weight of sodium caseinate is 0.25% of the weight of the cream, and the addition of whey protein powder The weight is 0.4% of the weight of the cream, and the added weight of Palatase20000L lipase is 0.5‰ of the weight of the cream; the mixture is incubated at 50°C for 4 hours to obtain an enzymatic hydrolysis product; the enzymatic hydrolysis product is pasteurized (enzyme-inactivated) , homogenized to obtain about 940 g of enzymatic hydrolyzed cream 2;

[0098] (3) adding 60 g of white granulated sugar to the enzymatic hydrolysis cream 2 obtained in step (2), and stirring the mixture for 15 to 20 minutes at 55°C to 60°C to obtain a mi...

experiment example 1

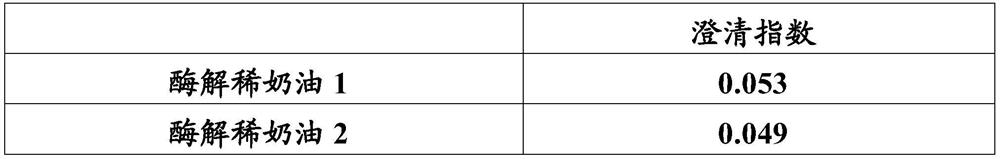

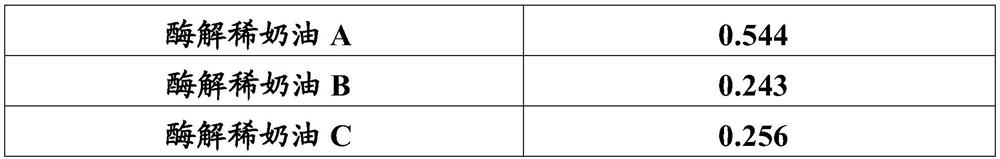

[0112] Experimental Example 1 Antioxidant Detection

[0113] (1) The antioxidant properties of enzymatic hydrolyzed cream 1-2 and A-C were detected, and the results are shown in Table 1.

[0114] Detection method: Put 1.0 mL of anhydrous ethanol solution containing 1.865 mmol / L phenanthroline into a test tube with a stopper, then add 2 mL of 0.2 M phosphate buffer (pH 7.4) and 1 mL of the sample and mix thoroughly. Then add 1.0 mL of FeSO with a concentration of 1.865 mmol / L 4 ·7H 2 The O solution was thoroughly mixed, and finally 1.0 mL of 0.03% (v / v) H was added. 2 O 2 , in a constant temperature water bath at 37°C for 60 minutes to obtain a mixed solution. Measure the absorbance value of the mixed solution at 536nm, denoted as A S ; Use distilled water instead of sample as blank group, and the absorbance value measured at 536nm is recorded as A b ; replace H with distilled water 2 O 2 As the damage group, the absorbance value at 536 nm was measured and recorded as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com