Monocrystalline silicon rod cutting device based on monocrystalline silicon wafer production and method

A technology of single crystal silicon rods and single crystal silicon wafers, applied in the field of single crystal silicon rod cutting devices based on the production of single crystal silicon wafers, can solve the problem that the production process of single crystal silicon wafers cannot continue to be popularized and used, increase the labor intensity of workers, reduce Monocrystalline silicon wafer production efficiency and other issues, to achieve the effect of reducing labor intensity, improving rolling efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

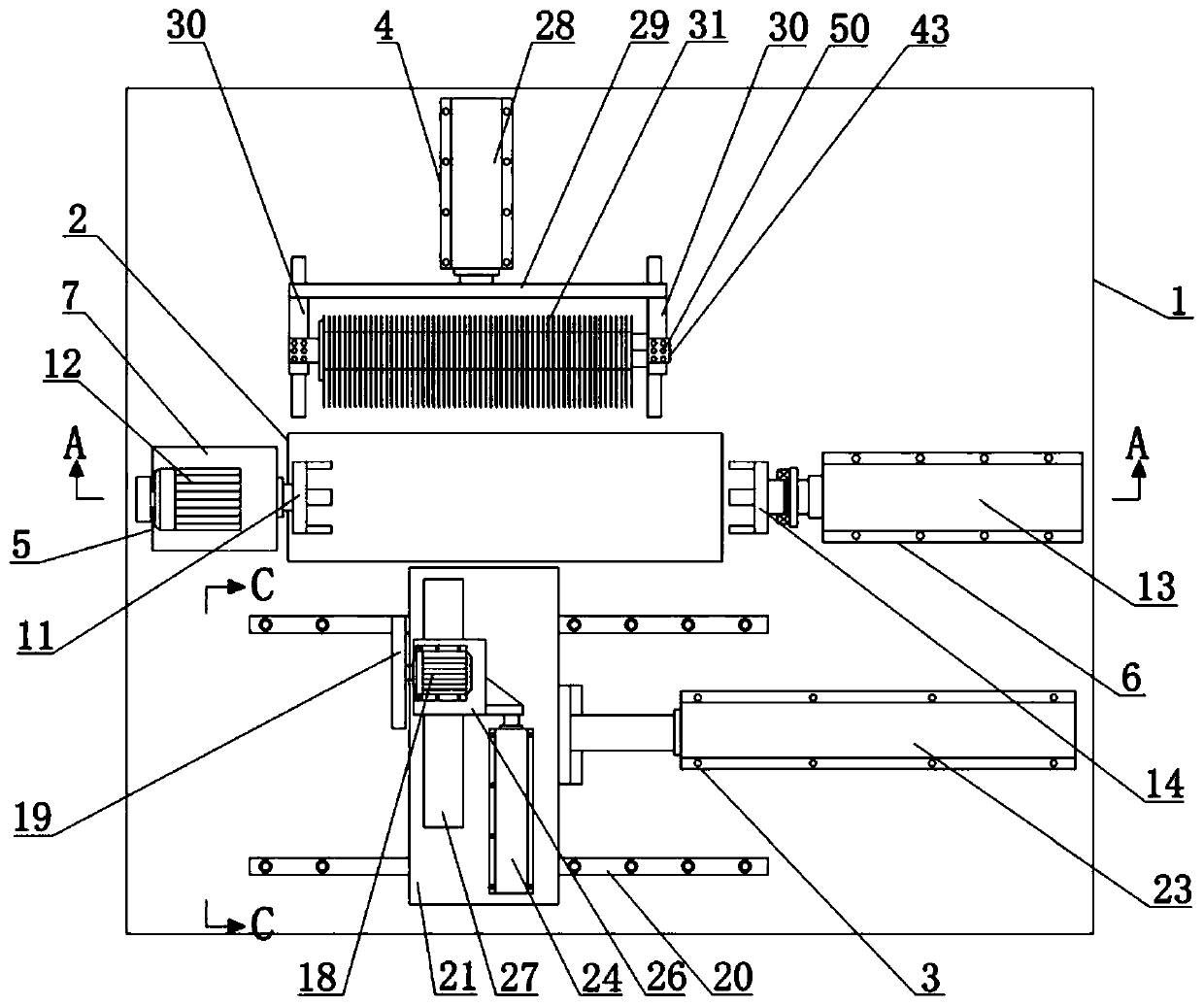

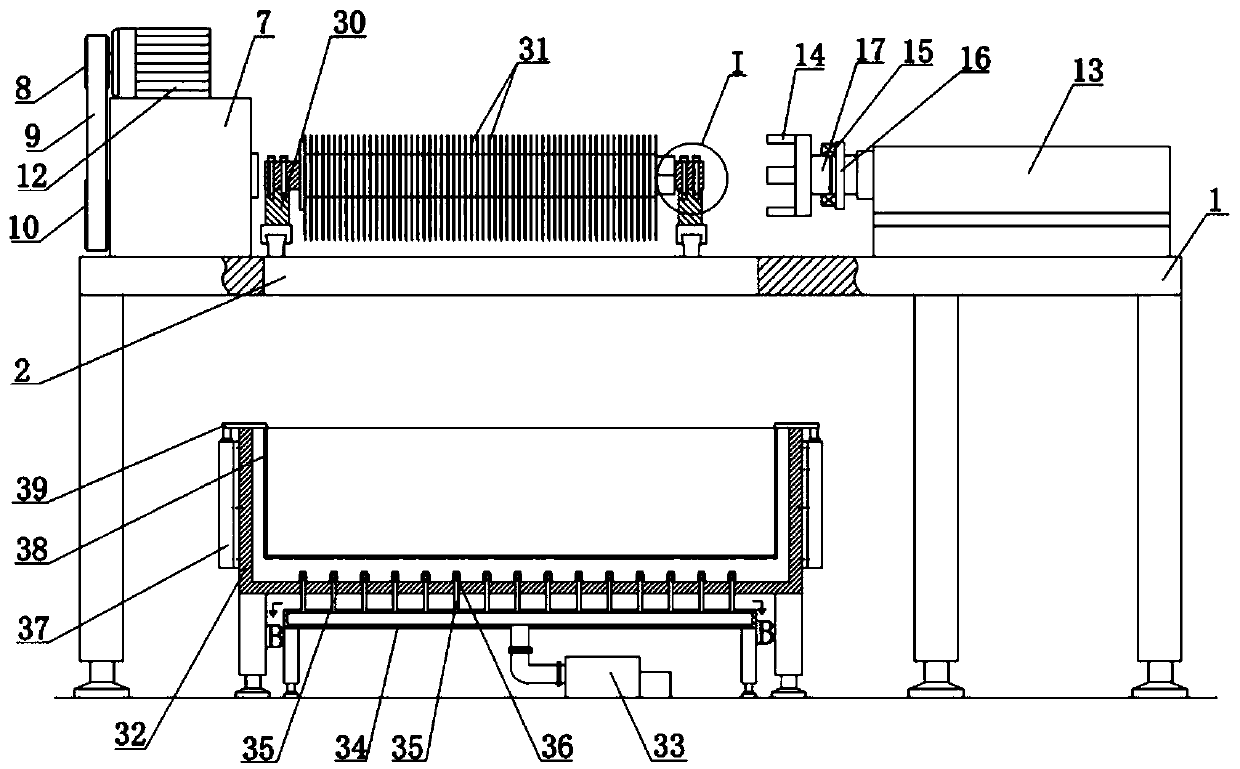

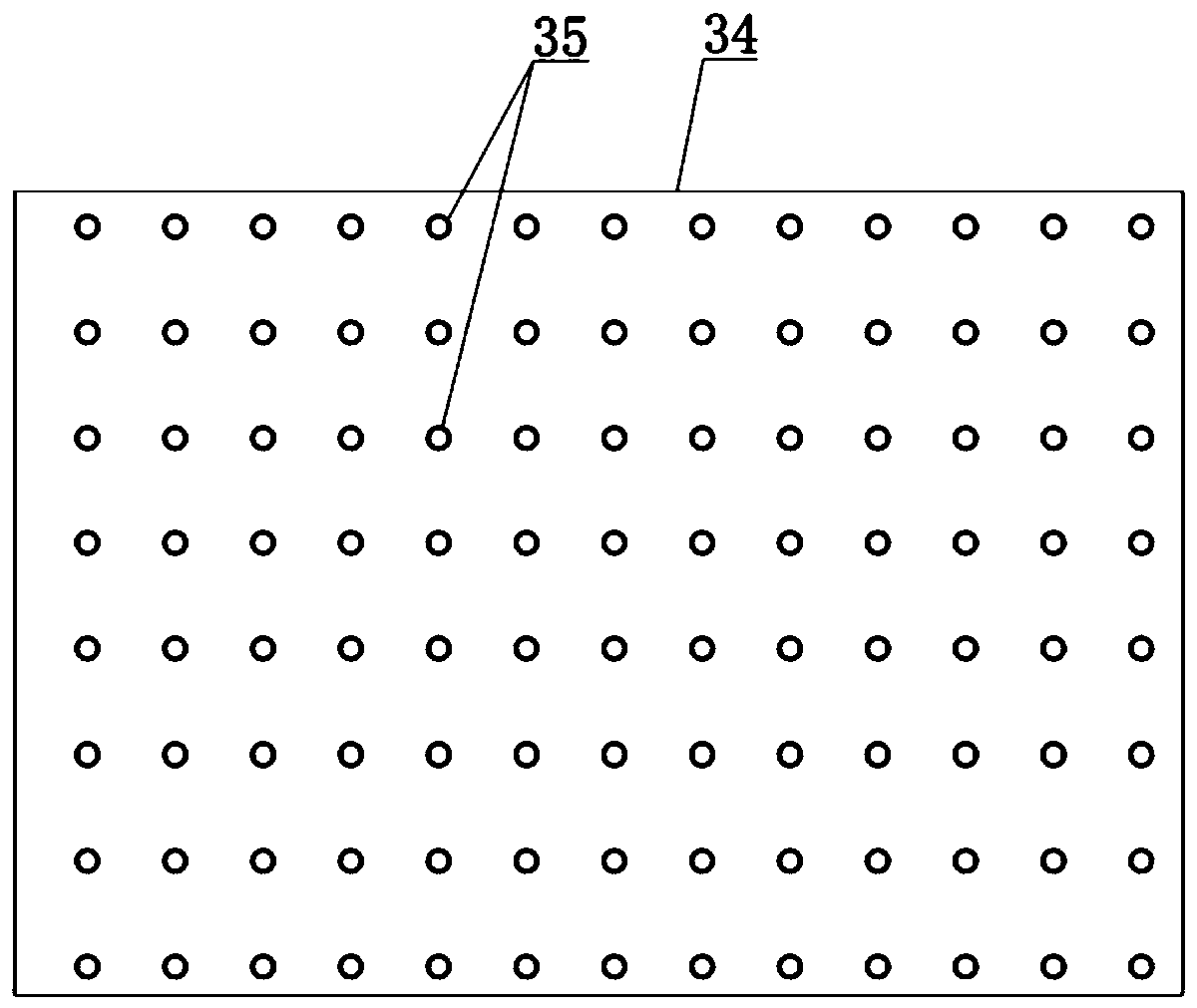

[0049] Embodiment one: if Figure 1~2 As shown, a single crystal silicon rod cutting device based on the production of single crystal silicon wafers, it includes a workbench 1, a through groove 2 opened on the top of the workbench 1, and the top surface of the workbench 1 is located in the through groove 2 A single crystal silicon rod rolling device 3 and a slicing device 4 are respectively provided on the front and rear sides of the workbench 1, and a left clamping device 5 and a right clamping device 6 are respectively provided on the top surface of the workbench 1 and on the left and right sides of the through groove 2 , A single crystal silicon wafer cleaning device is provided directly below the through groove 2 .

[0050] Such as Figure 1~2 As shown, the left clamping device 5 includes a speed reducer 7, a driving pulley 8, a belt 9, a driven pulley 10, a three-jaw chuck I11 and a motor I12, and the speed reducer 7 is fixed on the top surface of the workbench 1 Above,...

Embodiment 2

[0068] Embodiment two: if Figure 11 As shown, a single crystal silicon rod cutting device based on the production of single crystal silicon wafers, the difference between this embodiment and the first embodiment is that it also includes a controller 51, and the controller 51 communicates with the motor I12, the motor II18, the hydraulic cylinder 13. Feed oil cylinder 28, vertical oil cylinder 37, horizontal oil cylinder 23, and longitudinal oil cylinder 24 are electrically connected, and the extension of the piston rod of feed oil cylinder 28, vertical oil cylinder 37, horizontal oil cylinder 23, and longitudinal oil cylinder 24 can be controlled by the controller 51 or retract, and at the same time, it can also control the start or close of the motor I12 and the motor II18, which is convenient for workers to operate and has the characteristics of a high degree of automation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com