A kind of n-butyraldehyde one-step conversion method for preparing butyl butyrate

A technology of butyl butyrate and n-butyraldehyde, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of large discharge of "three wastes", equipment corrosion, and many side reactions, and achieve raw material High conversion rate and product selectivity, mild reaction conditions, and good atom economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

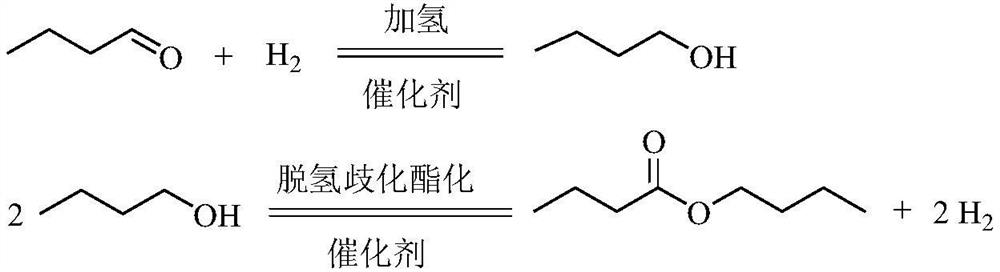

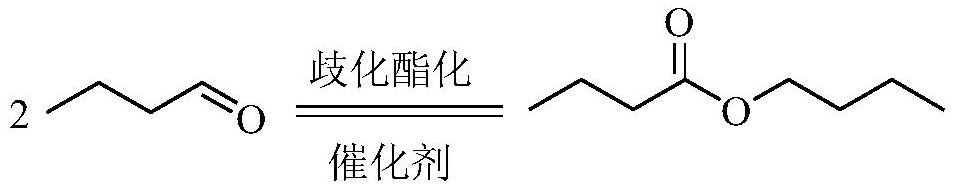

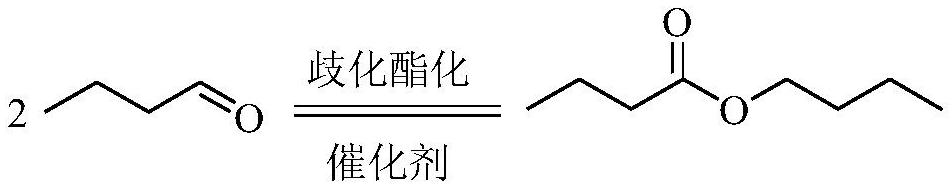

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 20 grams of n-butyraldehyde and 0.1 gram of aluminum glycinate (0.5% of the quality of n-butyraldehyde) into 100 ml of two-necked round-bottomed flasks equipped with condenser tubes, control the reaction temperature by a refrigerator to be 10° C., stir and react for 2 hours, After the reaction, the mixture is qualitatively and quantitatively analyzed by gas chromatography-mass spectrometry, and the conversion rate of n-butyraldehyde and the selectivity of butyl butyrate are both above 99%.

Embodiment 2~5

[0034] The specific method of Examples 2-5 is similar to that of Example 1, and the specific reaction conditions and results are shown in Table 1. Using aluminum lysine, aluminum alanine, aluminum trimethyl tryptophan, aluminum glutamate and other amino acid aluminum as catalysts, the amount of catalyst is 0.2-1.0% of the mass of n-butyraldehyde, the reaction temperature is 0-20°C, the reaction The time is 0.5-2 hours, and the conversion rate of n-butyraldehyde and the selectivity of butyl butyrate can reach more than 99%.

[0035] Table 1. One-step conversion of n-butyraldehyde to prepare butyl butyrate

[0036]

Embodiment 6

[0038] Catalyst recycling. After the reaction in Example 1, the product was distilled and separated, the catalyst was left in the reaction flask, and 20 g of n-butyraldehyde was added to repeat the reaction at 10° C. for 2 hours. The catalyst was recycled three times, the conversion rates of n-butyraldehyde were 99%, 98%, 98%, and the selectivities of butyl butyrate were 99%, 99%, 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com