Preparation method of clethodim and intermediate thereof

A technology for clethodim and intermediates, applied in the field of clethodim preparation, can solve the problems of affecting the yield and product quality, increasing the burden of wastewater treatment, high ammonia nitrogen content, etc., achieving easy separation and purification, increasing the burden of wastewater treatment, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

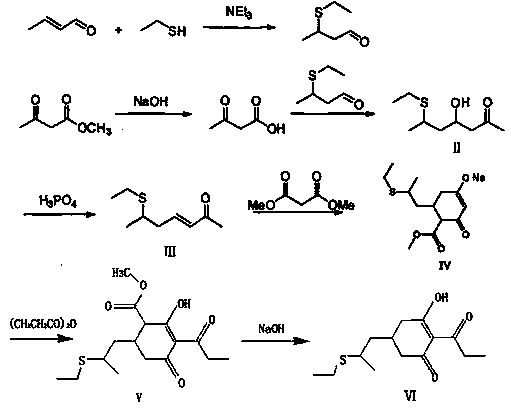

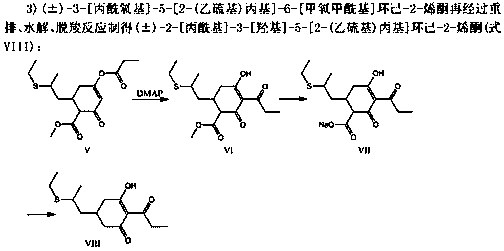

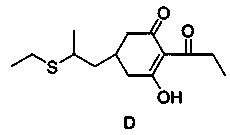

Method used

Image

Examples

Embodiment 1

[0056] 1. Refer to the method of patent 201710535450.4 to prepare 6-ethylthio-3-hepten-2-one toluene solution.

[0057] 2. Put 45g of sodium methoxide methanol solution with a mass concentration of 30% into a 500ml three-necked flask, distill off the methanol, then add 250g of toluene and 40g of diethyl malonate, stir for 1h, and then dropwise add 30wt% of 6-Ethylthio-3-hepten-2-one toluene solution 137g, dropwise time is 1h, after dropping, keep warm at 40°C for 1h for cyclization reaction, after reaction, heat up to 70°C for dealcoholization, and add 120g of toluene at the same time, After dealcoholization is finished, obtain the mixture of 240g compound A and toluene, compound A structural formula is as follows:

[0058] .

[0059] 3. Filter the mixture of compound A and toluene obtained above to remove impurities, put the obtained compound A into a three-necked flask filled with 200g of toluene, and pass hydrogen chloride gas into the reaction solution at 15°C until the...

Embodiment 2

[0064] 1. Refer to the method of patent 201710535450.4 to prepare 6-ethylthio-3-hepten-2-one toluene solution.

[0065] 2. Put 45g of sodium methoxide methanol solution with a mass concentration of 30% into a 500ml three-necked flask, distill off the methanol, then add 250g of benzene and 33g of dimethyl malonate, stir for 1h, and then add dropwise 30wt% of 137g of 6-ethylthio-3-hepten-2-one toluene solution, the time of dropping is 1h, and after the dropping is completed, the cyclization reaction is kept at 40°C for 1h, and after the reaction, the temperature is raised to 70°C for dealcoholization, and 120g of benzene is added at the same time. After dealcoholization is completed, obtain the mixture of 225g compound A and benzene, compound A structural formula is as follows:

[0066]

[0067] 3. Filter the compound A and benzene mixture obtained above to remove impurities, put the obtained compound A into a three-necked flask with 200 g of benzene, and feed hydrogen bromid...

Embodiment 3

[0072] 1. Refer to the method of patent 201710535450.4 to prepare 6-ethylthio-3-hepten-2-one toluene solution.

[0073] 2. Put 45g of sodium methoxide methanol solution with a mass concentration of 30% into a 500ml three-necked flask, distill off the methanol, then add 250g of toluene and 19g of methyl acetate, and then add dropwise 6-ethylthio with a content of 30wt% at 40°C - 3-hepten-2-one toluene solution 137g, dropwise time is 1h, after dropping, keep warm at 40°C for 1h, heat up to 70°C to remove solvent, add 120g toluene at the same time, after dealcoholization , obtain the mixture of 190g compound A and toluene, compound A structural formula is as follows:

[0074]

[0075] 3. Filter the mixture of compound A and toluene obtained above to remove impurities, put the obtained compound A into a three-necked flask equipped with 200g toluene, add 30wt% hydrochloric acid solution to the reaction solution at 0°C until pH3 left and right, standing and stratifying, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com