Water-soluble acrylic stabilizer and preparation method thereof

A technology of water-soluble acrylic acid and acrylic acid, which is applied in the field of thickening and stabilizing agents, can solve the problems of unsatisfactory emulsion polymerization effect and storage stability, and achieve the effects of improving distillation stability, storage and use performance, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

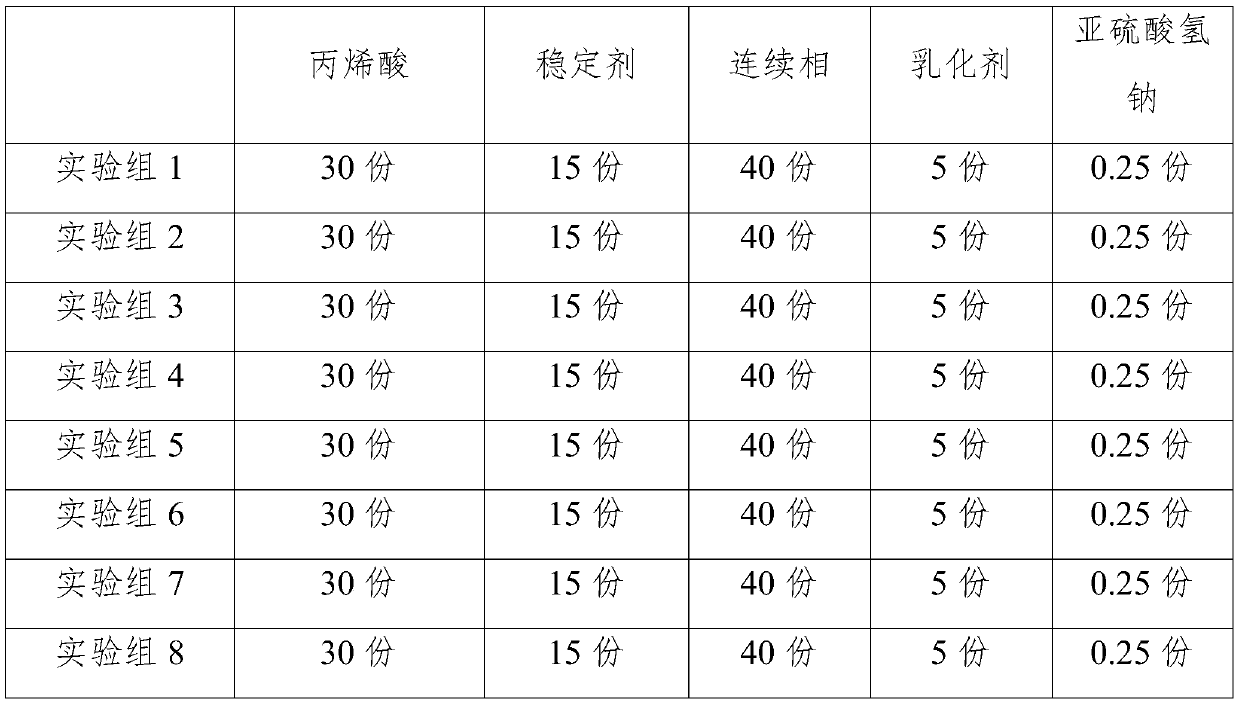

Examples

preparation example Construction

[0035] A preparation method of a water-soluble acrylic stabilizer, comprising the following steps:

[0036] (1) Add 50% by weight of water into the reactor, then add acrylic acid monomer and itaconic acid, slowly add neutralizer dropwise after stirring evenly, keep stirring, and keep the neutralization temperature not exceeding 40°C, And the pH value is controlled at 4.5-5.5;

[0037] (2) Add acrylamide or acrylamide sulfonate to step (1), and stir until completely dissolved;

[0038] (3) Add molecular weight regulator and 50% water by weight to step (2) and stir evenly to obtain a mixed solution;

[0039] (4) After taking out 20% of the mixed solution in step (3) and heating it to 60-70° C., add the initiator, add the initiator after heating up, and the initiator will release more free radicals, thereby The reaction is initiated faster, and the molecular weight distribution of the polymer after the reaction is more uniform. After the temperature reaches 70°C, the remaining ...

Embodiment 1

[0042] A water-soluble acrylic stabilizer, comprising the following components in parts by weight: 10 parts of methacrylic acid, 2 parts of itaconic acid, 40 parts of acrylamide, 15 parts of 25% liquid caustic soda, 0.05 part of sodium formate, persulfuric acid Potassium 0.5 parts, water 120 parts. It should be noted that the acrylamide in the stabilizer component can also be selected from acrylamide sulfonate.

[0043] A preparation method of a water-soluble acrylic stabilizer, comprising the following steps:

[0044] (1) Add 60 parts of water into the reactor, then add methacrylic acid and itaconic acid, stir evenly, slowly add 25% liquid caustic soda dropwise, keep stirring, and keep the neutralization temperature at 30°C to neutralize the pH value Controlled at 4.5;

[0045] (2) Add acrylamide or acrylamide sulfonate to step (1), and stir until completely dissolved;

[0046] (3) Add sodium formate and 60 parts of water to the step (2) and stir evenly to obtain a mixed sol...

Embodiment 2

[0049] A water-soluble acrylic stabilizer, comprising the following components in parts by weight: 30 parts of methacrylic acid, 8 parts of itaconic acid, 30 parts of acrylamide, 20 parts of 25% liquid caustic soda, 0.1 part of sodium formate, persulfuric acid Potassium 1.0 parts, water 140 parts. It should be noted that the acrylamide in the stabilizer component can also be selected from acrylamide sulfonate.

[0050] A preparation method of a water-soluble acrylic stabilizer, comprising the following steps:

[0051] (1) Add 70 parts of water into the reactor, then add methacrylic acid and itaconic acid, stir evenly, slowly add neutralizer dropwise, keep stirring, and keep the neutralization temperature at 35°C, and control the neutralization pH value at 5.5;

[0052] (2) Add acrylamide or acrylamide sulfonate to step (1), and stir until completely dissolved;

[0053] (3) Add sodium formate and 70 parts of water to the step (2) and stir evenly to obtain a mixed solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com