Paper-based functional material for oil-water separation, preparation method and application thereof

A functional material, oil-water separation technology, applied in the field of water treatment, can solve the problems of low separation efficiency, high energy consumption, secondary pollution, etc., to improve strength, optimize oil-water separation performance, improve hydrophilicity and underwater oil-water separation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

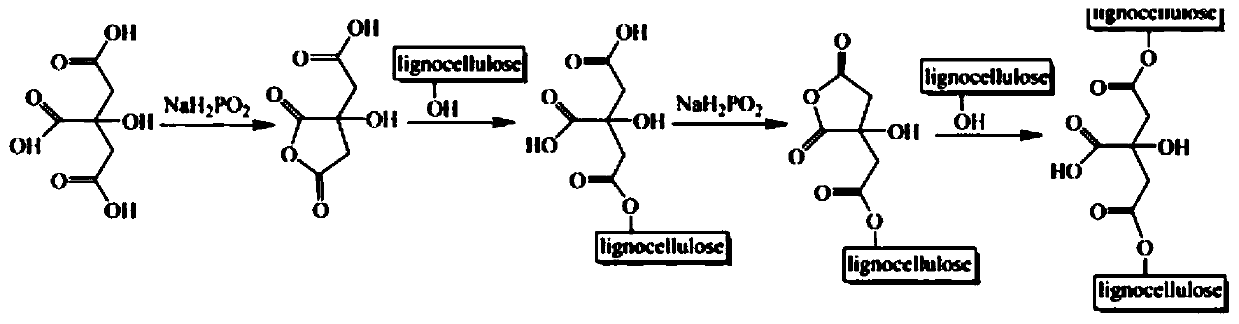

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of paper-based functional material for oil-water separation

[0035] 1) Preparation of base paper

[0036] The bleached softwood chemical pulp board (dryness: 90wt%) was soaked in water at room temperature for 24 hours, and then torn into small pieces of 25×25mm, and then the pulp was decomposed for 5 minutes with a fiber standard disintegrator at a concentration of 1wt%. The pulp concentration after decomposing was concentrated to 10wt%, and the pulp was beaten with a PFI refiner (KRK, Kumagai Riki Kogyo), and the rotation speed was set at 1500 rpm, 3000 rpm, and 4000 rpm, respectively. The Choppel beating degree meter (ZJ-100) was used to measure the beating degree at different speeds, as shown in Table 1. Take the pulp suspension equivalent to 2.2g of absolute dry pulp and add it to the shaper of the sheet machine (RK-3A, Austria). When the slurry volume is diluted to 4L, add 300ppm (corresponding to the absolute dry pulp) of 0.2wt %CPAM, the basis...

Embodiment 2

[0042] Example 2 Preparation of paper-based functional material for oil-water separation

[0043] 1) Preparation of base paper

[0044] Poplar chemical pulp (dryness: 65.8 wt%) was soaked in water at room temperature for 24 hours to form a pulp with a concentration of 1 wt%. The pulp was then decomposed for 5 minutes with a fiber standard disintegrator. The pulp concentration after decomposing was concentrated to 10wt%, and the pulp was beaten with a PFI refiner (KRK, Kumagai Riki Kogyo), and the rotation speed was set at 3500 rpm, 4000 rpm, and 4500 rpm. The Choppel beating degree meter (ZJ-100) was used to measure the beating degree at different speeds, as shown in Table 2. Take the pulp suspension equivalent to 1.9g of absolute dry pulp and add it to the former of the sheet machine (RK-3A, Austria). When the volume of the slurry is diluted to 4L, add 0.2wt of 300ppm (relative to the absolute dry pulp) %CPAM, the basis weight of each paper is set to 60g / m 2 . After vacuum fil...

Embodiment 3

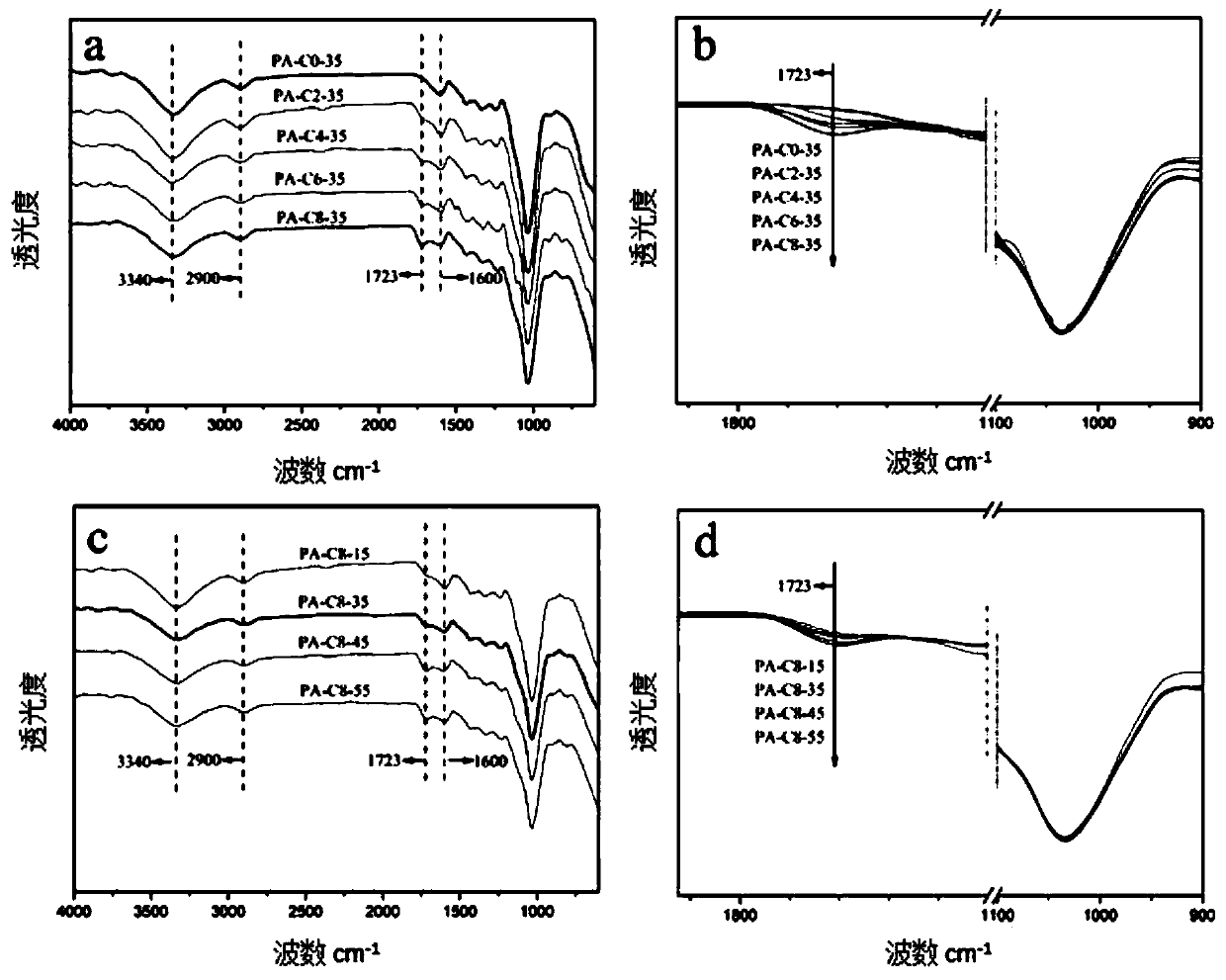

[0052] Example 3 Performance test of paper-based functional materials

[0053] Strength measurement method: All paper samples are placed in a constant temperature and humidity room at 50% relative humidity and 23°C for 24 hours. According to the Standard Test Method of the Technical Association of Pulp and Paper Industry (TAPPI), the dry tensile strength and wet tensile strength of the treated paper were measured. When measuring the wet tensile strength of the paper, immerse the sample in water to ensure that the moisture content of the paper is 50% (allowable error ± 2%). The measurement is repeated 6 times for each sample. Figure 4 It is the tensile strength of different paper-based functional materials. by Figure 4 (a) It can be seen that the dry tensile strength of the paper modified by citric acid has been improved, but the citric acid concentration has no obvious influence on the dry tensile strength of the paper. by Figure 4 (b) It can be found that compared with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com