Flue gas pretreatment device and method based on osmotic membrane and cold-dry method fusion technology

A pretreatment device, permeable membrane technology, applied in measurement devices, preparation of test samples, volume/mass flow rate generated by mechanical effects, etc. problems, to achieve the effect of improving flexibility and convenience, improving accuracy, and reducing use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

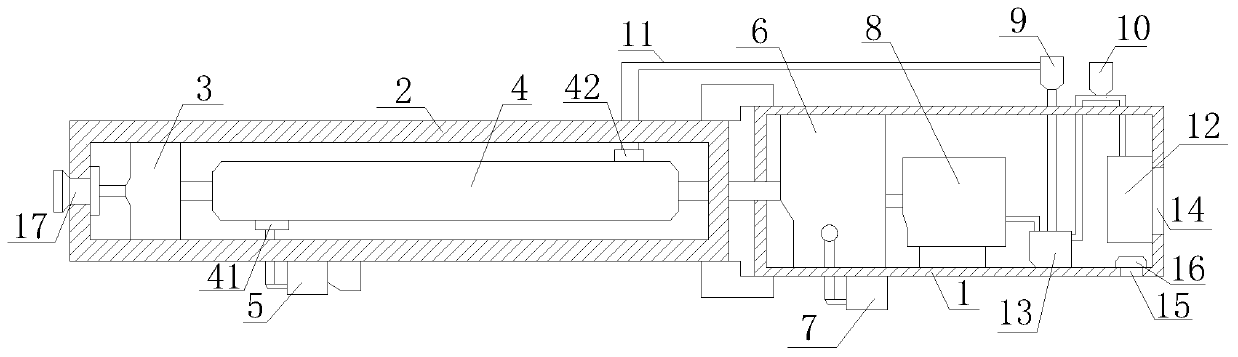

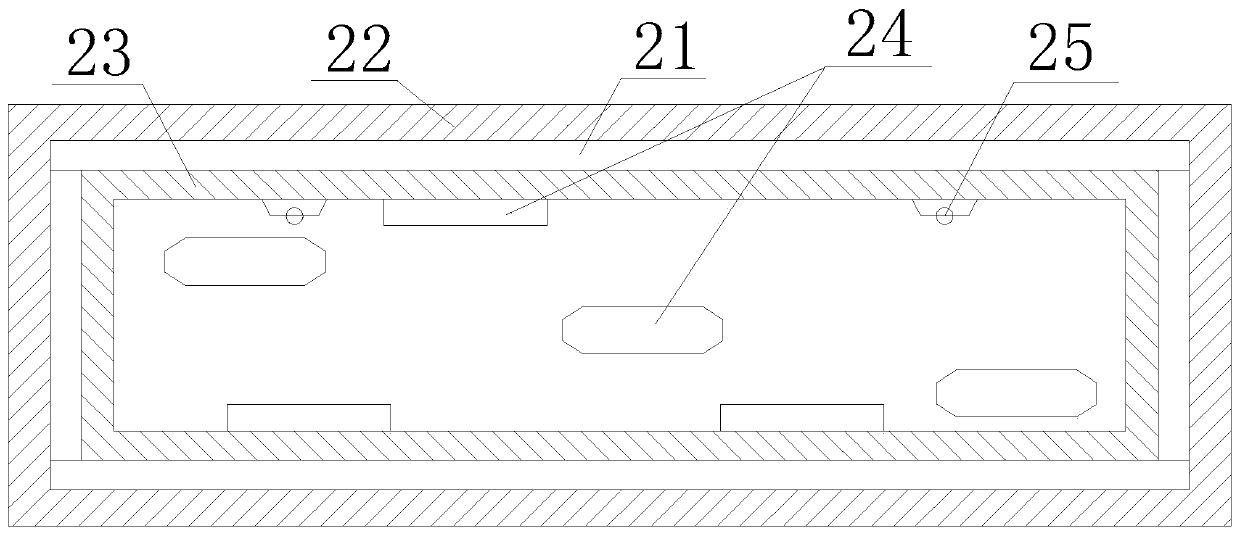

[0021] Such as figure 1 and 2 As shown, a flue gas pretreatment device based on the fusion technology of osmotic membrane and cold-drying method includes a bearing shell 1, a heating insulation box 2, a filter 3, a permeation tube 4, an exhaust pump 5, a condenser 6, and a drainage peristaltic Pump 7, sampling pump 8, rotameter I9, rotameter II10, diversion branch pipe 11 and dew point measurement unit 12, the bearing shell 1 and the heating insulation box 2 are all closed cavity structures with a rectangular cross section, and the bearing The shell 1 and the heating insulation box 2 are connected to each other, and the filter 3 and the permeation tube 4 are embedded in the heating insulation box 2. The front end of the permeation tube 4 communicates with the filter 3, and the rear end of the permeation tube 4 communicates with the condenser 6 through the guide tube. In addition, an exhaust port 41 is provided on the side surface of the first half of the permeation pipe 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com