Medicine microcapsule slow-release filtering material composition for epidemic prevention functional type gauze mask

A composition and functional technology, applied in the direction of drug combination, microcapsules, drug delivery, etc., can solve the problem that the mask filter element does not consider the long-term antibacterial and antiviral effect of the mask, and the physical and chemical structure damage of the filter material, etc., reaching the raw material market Sufficient supply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

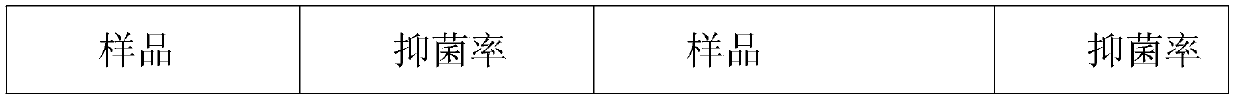

Embodiment 1

[0018] Using starch octenyl succinate as the wall material, 5 parts of herb oil, 5 parts of patchouli oil, 2 parts of angelica oil, 6 parts of perrin oil, 3 parts of cinnamon oil, 2 parts of camphor oil, 10 parts of clove oil, and eucalyptus oil 8 parts and 2 parts of peppermint oil are core materials. Water bath at 60-90°C for 10-30min until starch octenyl succinate is gelatinized, after cooling to room temperature, add 5 parts of herb oil, 5 parts of Huoxiang oil, 2 parts of Angelica oil, 6 parts of Perrin oil, 3 parts of cinnamon oil, camphor Mix 2 parts of oil, 10 parts of clove oil, 8 parts of eucalyptus oil, 2 parts of peppermint oil, and 2 parts of 2000ppm nano-silver solution, and disperse at a high speed of 6000-10000 r / min for a certain period of time to obtain milky drug microcapsule liquid or spray After drying, it is made into solid microcapsule powder of medicine. The drug microcapsule liquid and the drug solid microcapsule powder are respectively attached to th...

Embodiment 2

[0020]Using starch octenyl succinate as the wall material, 5 parts of herb oil, 5 parts of patchouli oil, 2 parts of angelica oil, 6 parts of perrin oil, 3 parts of cinnamon oil, 2 parts of camphor oil, 10 parts of clove oil, and eucalyptus oil 8 parts and 2 parts of peppermint oil are core materials. Water bath at 60-90°C for 10-30 minutes until starch octenyl succinate is gelatinized. After cooling to room temperature, add 5 parts of herb oil, 5 parts of Huoxiang oil, 2 parts of Angelica oil, 6 parts of Perrin oil, 3 parts of cinnamon oil, and camphor Mix 2 parts of oil, 10 parts of clove oil, 8 parts of eucalyptus oil, and 2 parts of peppermint oil, and disperse at a high speed of 6000-10000r / min for a certain period of time to obtain milky drug microcapsules or spray-dry to make drug solid microcapsules powder. The drug microcapsule liquid and the drug solid microcapsule powder are respectively attached to the surface of the non-woven fabric to form a drug microcapsule sl...

Embodiment 3

[0022] Combination of the following medicinal raw materials in parts by weight: 8 parts of herb oil, 2 parts of Huoxiang oil, 4 parts of Angelica oil, 8 parts of Perrin oil, 4 parts of cinnamon oil, 4 parts of camphor oil, 10 parts of clove oil, and 10 parts of eucalyptus oil 3 parts, 3 parts of peppermint oil, 2 parts of 2000ppm nano silver solution, 30 parts of starch octenyl succinate. The effect of essential oil purity on the embedding rate of microcapsule powder was determined with clove oil as reference.

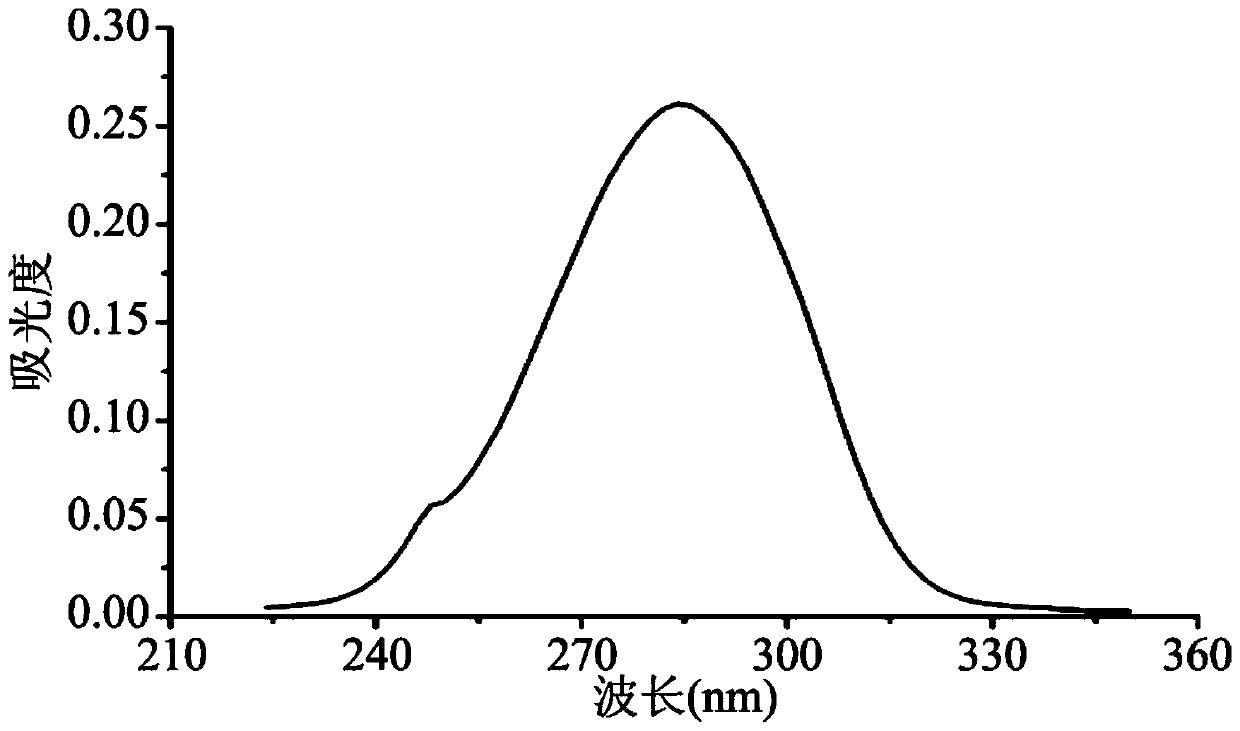

[0023] (1) Determination of the maximum absorption wavelength of clove oil Weigh a certain amount of clove oil, dissolve and dilute it with absolute ethanol, and prepare a clove oil solution with a certain concentration, and use absolute ethanol as a blank control, within the range of 200-900nm Scan at all wavelengths to determine the maximum absorption wavelength.

[0024] (2) Draw the standard curve of clove oil and accurately weigh 0.1g of clove oil to a 10mL volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com