Preparation method of electrostatic spun polysulfonamide electret composite filter material

A technology of composite filtration and nano-composite materials, which is applied in the field of preparation of electrospun sulfone fiber electret composite filter materials, can solve the problems of easy breeding of harmful microorganisms, secondary pollution, and insufficient removal of fine particles, and achieve charge storage Enhanced capacity and charge stability, low filtration resistance, and improved filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

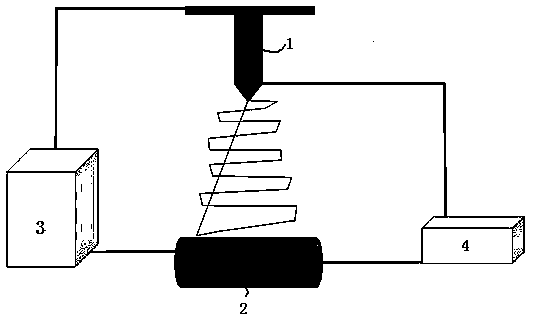

Image

Examples

Embodiment 1

[0029] An electrospun polysulfone electret composite filter material, with polysulfone fiber (polysulfone amide) as the matrix, adding PTFE nanoparticles to the polysulfone fiber, and preparing PTFE / polysulfone fiber nanocomposite fibers by electrospinning technology The membrane was prepared according to the following steps:

[0030] 1) Configuration of PTFE dispersion:

[0031] Dispersing 0.12g of PTFE nanoparticles in 5ml of N,N-dimethylformamide solvent, and ultrasonicating for 20-60min to obtain a solvent dispersion of PTFE nanoparticles, the diameter of the PTFE nanoparticles is 100-150nm;

[0032] 2) The configuration of PTFE / sulfonamide spinning solution:

[0033] Weigh 100g of polysulfone amide spinning solution with a mass fraction of 12%, add the solvent dispersion of the above-mentioned PTFE nanoparticles and mix, stir the mixed solution for 30min at a speed of 20000r / min with a high-shear emulsifying disperser, and then mix the mixed solution Ultrasonic degassin...

Embodiment 2

[0040] A kind of electrospun aryl sulfone fiber electret composite filter material, similar to embodiment 1, is prepared according to the following steps:

[0041](1) Configuration of PTFE dispersion:

[0042] Disperse 0.18 g of polytetrafluoroethylene nanoparticles in 5 ml of N,N-dimethylformamide solvent, and sonicate for 20 to 60 minutes to obtain a solvent dispersion of polytetrafluoroethylene nanoparticles.

[0043] (2) Configuration of tetrafluoroethylene / arylsulfon fiber spinning solution:

[0044] Take by weighing 100g mass fraction and be the polysulfone amide spinning solution of 12%, add the solvent dispersion liquid of above-mentioned polytetrafluoroethylene nanoparticles and mix, stir the mixed solution for 30min with the speed of 20000r / min with high-shear emulsification disperser, then Put the mixed solution into an ultrasonic bath for degassing for 120 minutes to form a uniformly mixed tetrafluoroethylene / arylsulfonamide spinning solution.

[0045] (3) Electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| piezoresistance | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com