Preparation process of ceramic composite membrane with metal protective layer

A technology of ceramic composite membrane and metal protective layer, applied in the field of membrane separation, can solve the problems of large adhesion of the membrane layer, large thermal expansion difference between metal and ceramic materials, etc., and achieve the effect of high connection strength, sealing and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

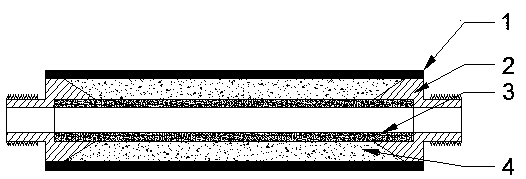

Image

Examples

Embodiment 1

[0019] 1. The ceramic membrane is φ16*2 mm, the rigid outer mold is a φ25*2 mm ceramic tube, and the head is made of stainless steel. The stainless steel powder with a particle size of 200 μm is put into the ceramic membrane, rigid outer mold and head. inside the mold;

[0020] 2. High-temperature sintering in a hydrogen atmosphere, the sintering temperature is 1200°C, heat preservation for 5 hours, and the composite film can be obtained by removing the rigid outer mold after cooling and taking it out.

Embodiment 2

[0022] 1. The ceramic membrane is made of φ32 mm 7-channel membrane tube, the rigid outer mold is made of φ40*2 mm molybdenum alloy tube, and the head is made of stainless steel. The stainless steel powder with a particle size of 50 μm is put into the ceramic membrane, rigid outer mold and In the mold composed of the head;

[0023] 2. High-temperature sintering in a helium atmosphere, the sintering temperature is 1050°C, heat preservation for 3 hours, cooling and taking out, removing the rigid outer mold to obtain a composite film.

Embodiment 3

[0025] 1. The ceramic membrane is φ16*2 mm, the rigid outer mold is φ25*2 mm ceramic tube, and the head is made of titanium metal. Titanium powder with a particle size of 100 μm is put into the ceramic membrane, rigid outer mold and head. inside the mold;

[0026] 2. High-temperature sintering under an argon atmosphere, the sintering temperature is 1200°C, heat preservation for 6 hours, and the composite film can be obtained by removing the rigid outer mold after cooling and taking it out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com