Tannin-polyethyleneimine composite material and application thereof

A polyethyleneimine and composite material technology, applied in the field of polymer chemistry, can solve the problems of easy loss, difficult separation and recovery of adsorbents, restricting the application of PEI, etc., and achieves the effect of broad application prospects and excellent adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

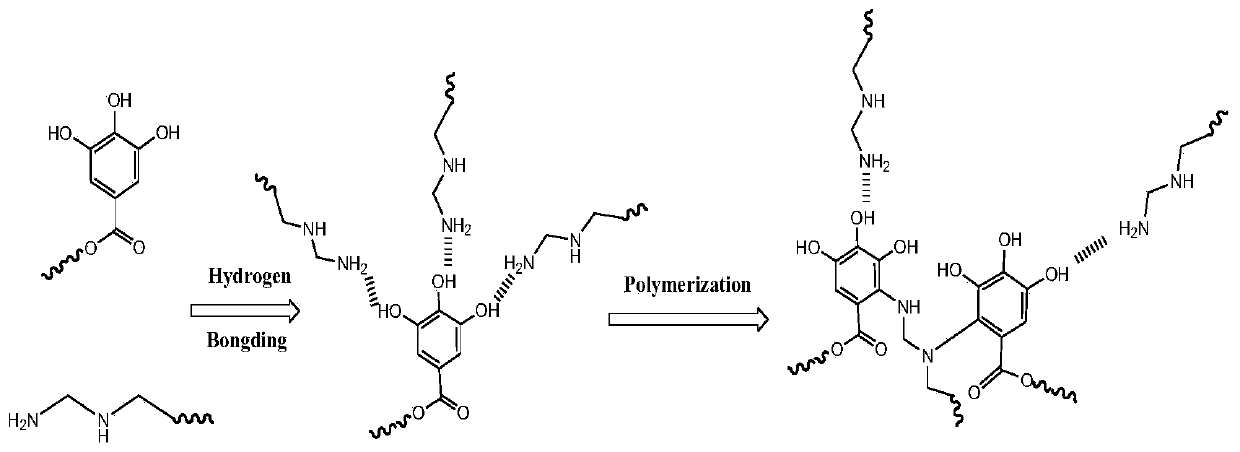

[0031] Embodiment 1 prepares tannin-polyethyleneimine composite material

[0032] (1) Prepare raw materials: prepare a tannin solution with a mass fraction of 1% and a polyethyleneimine solution with a mass fraction of 25%;

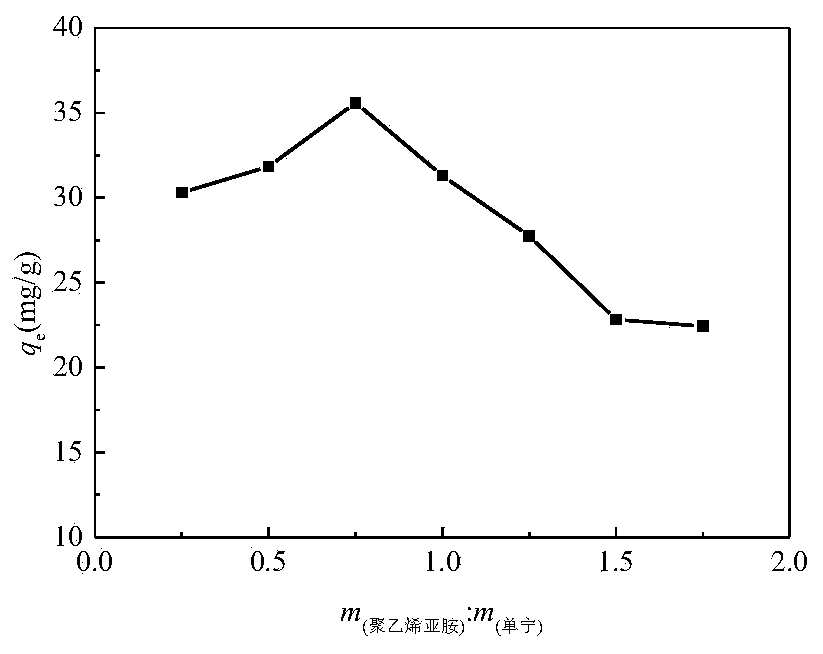

[0033] (2) The polyethyleneimine solution is added dropwise in the tannin solution, the volume ratio of the polyethyleneimine solution and the tannin solution is 1:100, that is, the polyethyleneimine participating in the reaction and the tannin mass ratio are 0.25, Stirring reaction at room temperature for 12 hours;

[0034] (3) The precipitate was collected by centrifugation, washed three times with distilled water, and dried at 50° C. for 12 hours to obtain the tannin-polyethyleneimine composite material.

Embodiment 2

[0035] Embodiment 2 prepares tannin-polyethyleneimine composite material

[0036] (1) Prepare raw materials: prepare a tannin solution with a mass fraction of 1% and a polyethyleneimine solution with a mass fraction of 25%;

[0037] (2) The polyethyleneimine solution is added dropwise in the tannin solution, the volume ratio of the polyethyleneimine solution and the tannin solution is 2:100, that is, the polyethyleneimine and tannin mass ratio participating in the reaction is 0.5, Stirring reaction at room temperature for 24 hours;

[0038] (3) The precipitate was collected by centrifugation, washed with distilled water for 4 times, and dried at 50° C. for 12 hours to obtain the tannin-polyethyleneimine composite material.

Embodiment 3

[0039] Embodiment 3 prepares tannin-polyethyleneimine composite material

[0040] (1) Prepare raw materials: prepare a tannin solution with a mass fraction of 1% and a polyethyleneimine solution with a mass fraction of 25%;

[0041] (2) The polyethyleneimine solution is added dropwise in the tannin solution, the volume ratio of the polyethyleneimine solution and the tannin solution is 3:100, that is, the polyethyleneimine and tannin mass ratio participating in the reaction is 0.75, Stirring reaction at room temperature for 24 hours;

[0042] (3) The precipitate was collected by centrifugation, washed five times with distilled water, and dried at 50° C. for 12 hours to obtain the tannin-polyethyleneimine composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com