Electrochemical gas sensor ultrasonic welding tool and method

A gas sensor, ultrasonic welding technology, applied in the direction of welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of unfavorable sensor label sticking to packaging, spending a lot of time to adjust, unbalanced welding, etc., to overcome frequent welding imbalance The effect of balancing phenomenon, saving manual operation time, and avoiding virtual welding and flashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be explained more clearly and completely through the description of preferred embodiments of the present invention in conjunction with the accompanying drawings.

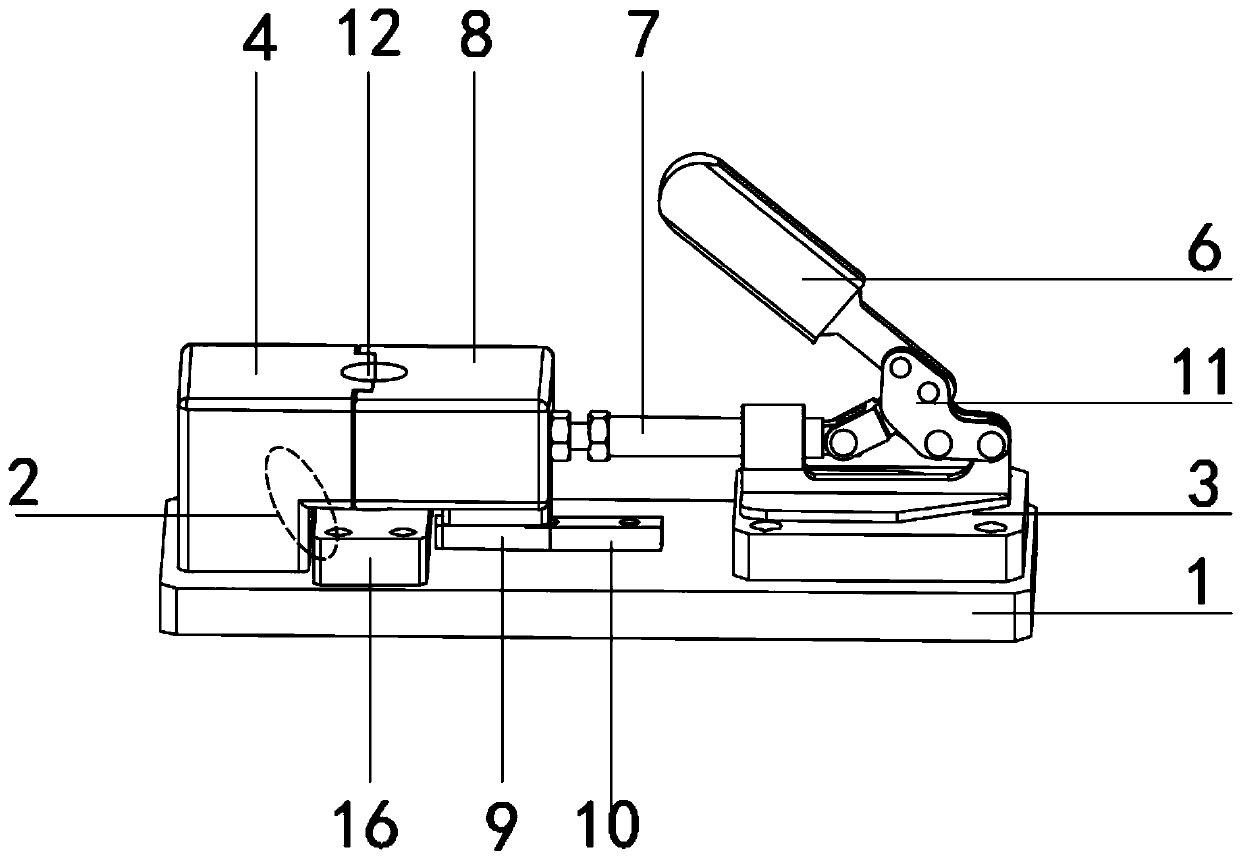

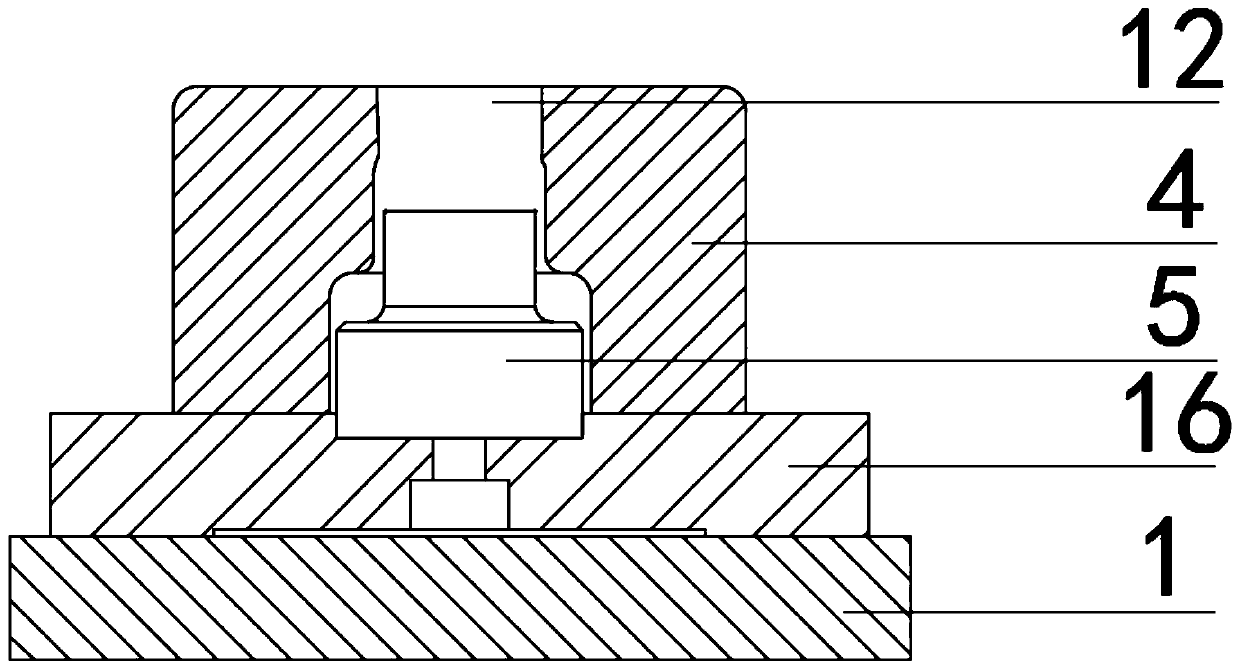

[0038] Such as figure 1 As shown, an ultrasonic welding tool for an electrochemical gas sensor according to the preferred embodiment of the present invention includes a base plate 1, and the left and right ends of the base plate 1 are respectively provided with a placing mechanism 2 and a pressing mechanism.

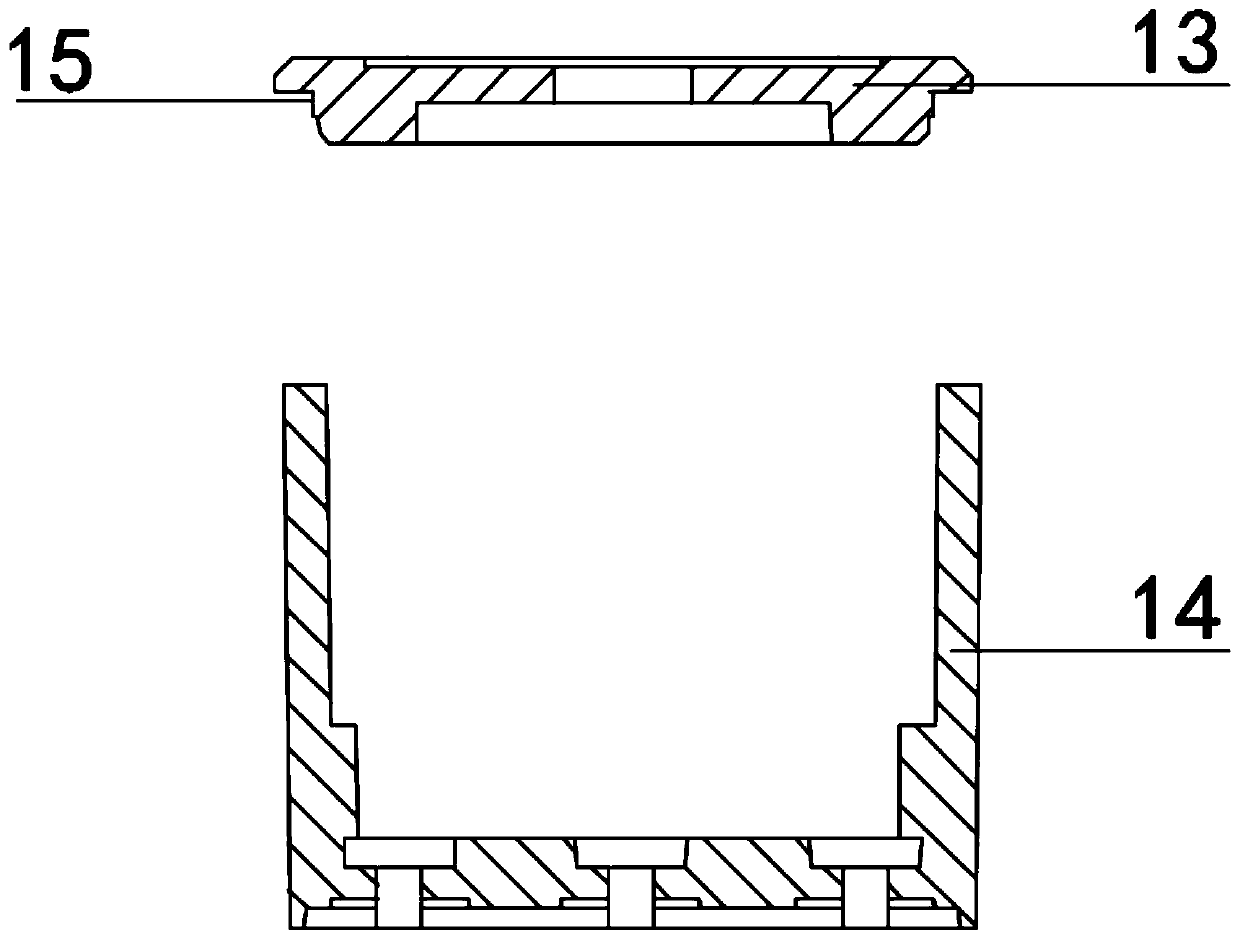

[0039] Such as image 3 As shown, the electrochemical gas sensor of this embodiment is applicable to the standard of the 4 series electrochemical gas sensor, which is a cylinder with an outer diameter of 20 mm, including a lower casing 14 and an upper cover 13, and is made of thermoplastic materials such as ABS and PE, and processed by machining Or it can be obtained by injection molding. In this embodiment, ABS material is used. The platform portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com