Manufacturing method of wrapped foam roll and prepared wrapped foam roll

A manufacturing method and foam technology, which are used in thin material processing, strip winding, transportation and packaging, etc., can solve the problems of low utilization rate of strip wrap foam, huge mold cost, efficiency problems, etc. The effect of automatic assembly, solving the high cost of mold and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

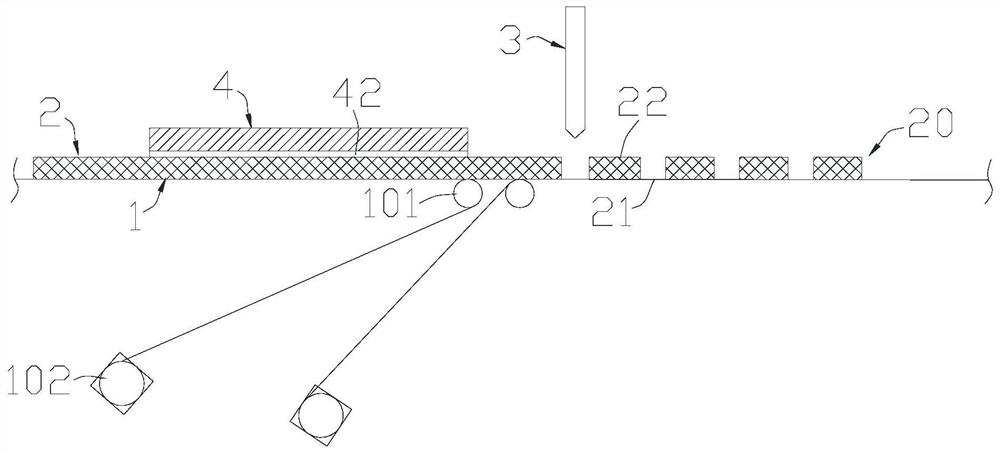

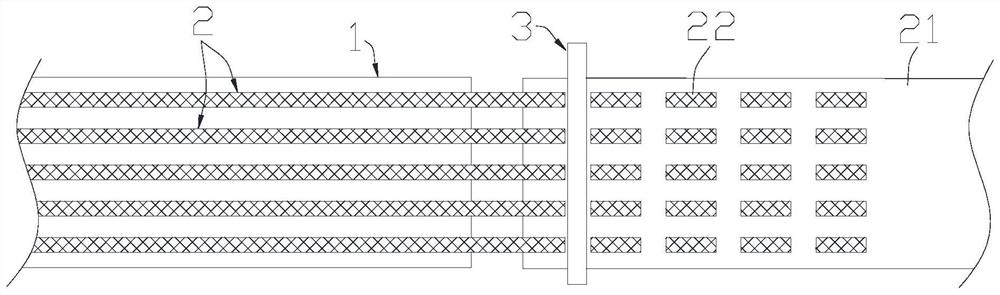

[0046] refer to figure 1 , 2 , the manufacturing method of wrapping foam roll material of one embodiment of the present invention, may comprise the following steps:

[0047] S1. Arranging a plurality of strips of wrapping foam 2 in parallel on the typesetting film 1 at intervals.

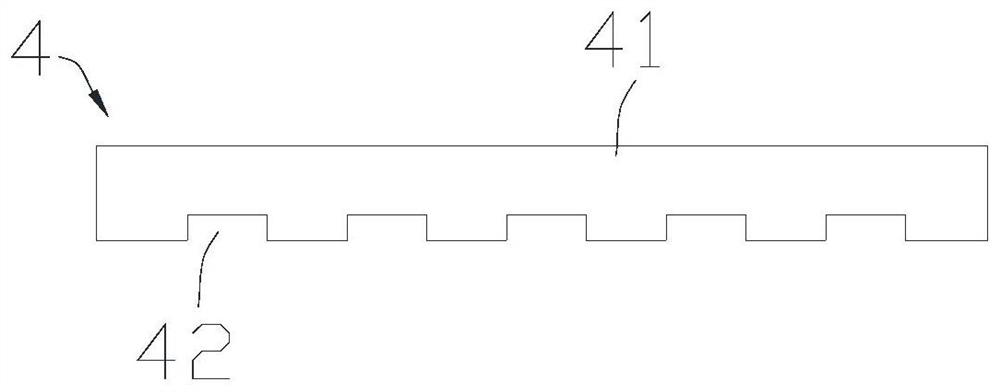

[0048] Each wrapped foam 2 includes a core and a base material wrapped outside the core; the core can be PU foam, silicone foam, etc., and the base material can be conductive cloth, copper foil, aluminum foil, conductive PI film, PI Membrane, graphite, Mylar, etc.

[0049] The length direction of the wrapped foam 2 is parallel to the length direction of the typesetting film 1 .

[0050] Preferably, at least two strips of wrapping foam 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com