Graphite negative electrode material, lithium ion battery, preparation method and application

A lithium-ion battery, graphite negative electrode technology, applied in the direction of battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of difficult acquisition of added components, complicated preparation process, low compaction density, etc., to achieve improved cycle Performance and capacity play, a wide range of sources, and the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

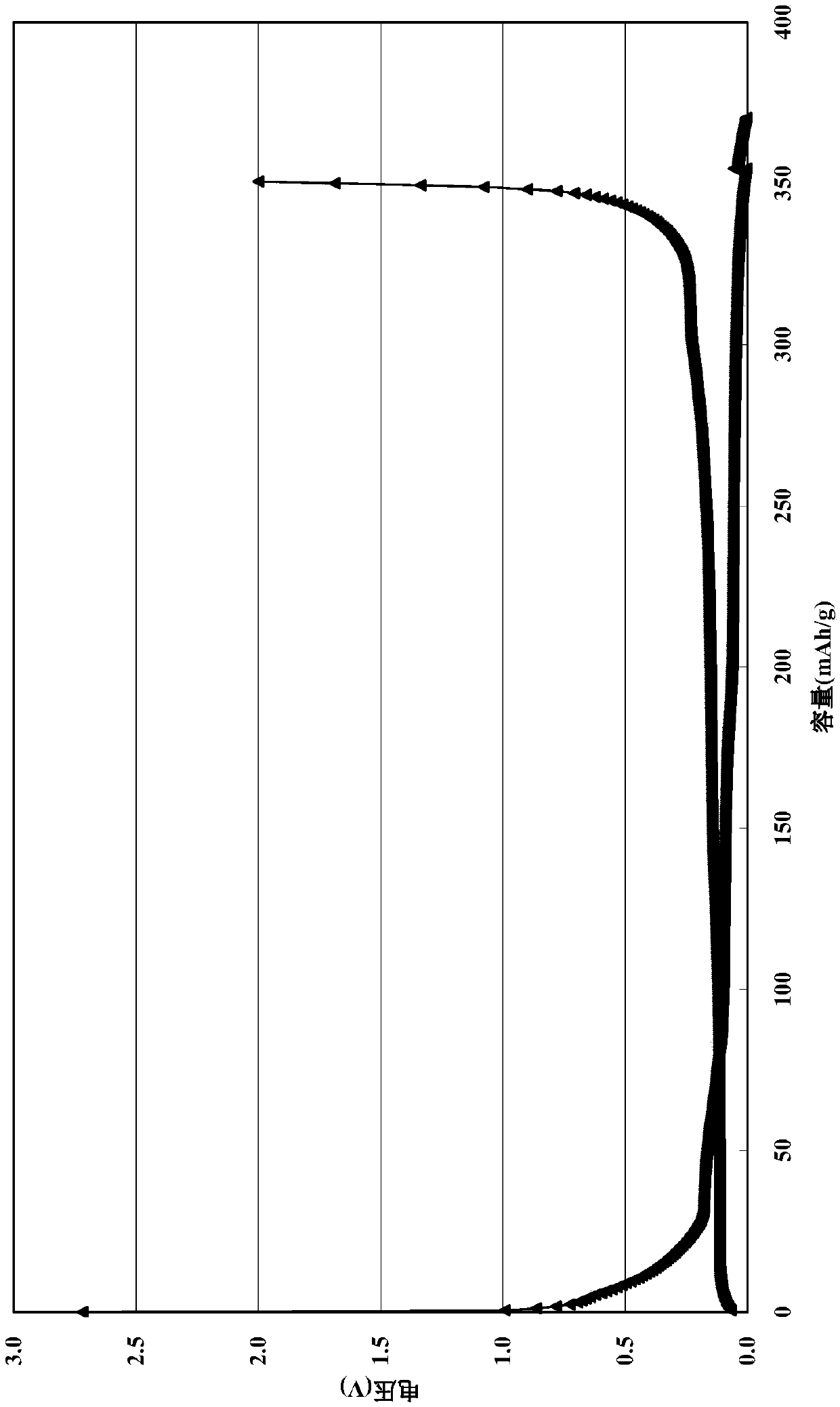

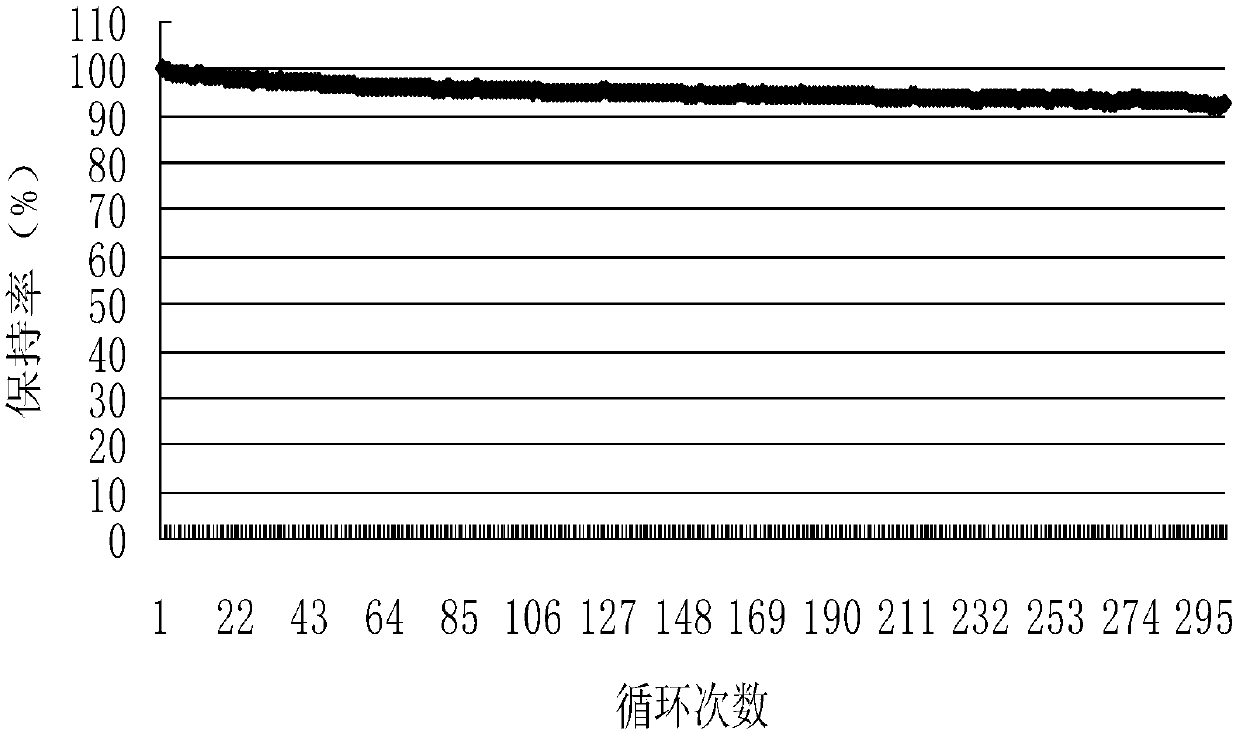

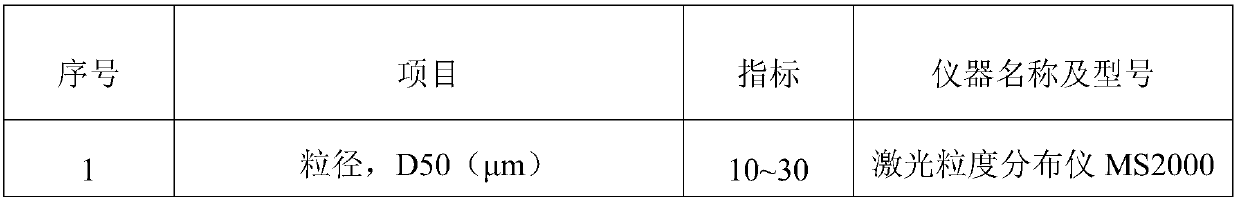

Embodiment 1

[0041] The raw mesophase carbon microspheres are crushed and classified in a crushing classifier to obtain F1 material (D50 is 25.6 μm), and 20 kg of F1 material is mixed with anthracite powder (D50 is 15.2 μm) 10 kg, catalyst (SiO 2 ) 1.6kg was alternately added in a cantilever double-helix conical mixer and mixed for 2 hours, then catalyzed graphitization (3000° C.) was carried out for 48 hours, and the composite graphite negative electrode material of the present invention was obtained. The half-cell capacity was 356.3mAh / g, and the initial efficiency was 91.6%. .

Embodiment 2

[0043] The raw mesophase carbon microspheres are crushed and classified in a crushing classifier to obtain F1 material (D50 is 25.6 μm), and 15 kg of F1 material is mixed with anthracite powder (D50 is 19.9 μm) 15 kg, catalyst (Fe 2 o 3 ) 2.5kg was alternately added in a cantilever double-helix conical mixer and mixed for 2 hours, then catalyzed graphitization (3200° C.) was carried out for 48 hours, and the composite graphite negative electrode material of the present invention was obtained. The half-cell capacity was 357.1mAh / g, and the initial efficiency was 93.4%. .

Embodiment 3

[0045] Mesophase carbon microspheres are crushed and classified in a crushing classifier to obtain F1 material (D50 is 20.7 μm), and 10 kg of F1 material is mixed with anthracite powder (D50 is 15.2 μm) 20 kg, catalyst (SnO 2 ) 3.2kg is alternately added in a cantilever double-helix conical mixer and mixed for 1 hour, then catalyzed graphitization (2800° C.) is processed for 36 hours, and the composite graphite negative electrode material of the present invention is obtained. The half-cell capacity is 355.9mAh / g, and the initial efficiency is 92.7%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com