A uv-fenton wastewater treatment process

A UV-FENTON, wastewater treatment technology, applied in the field of UV-FENTON wastewater treatment process, can solve the problems of high salt concentration in wastewater, high proportion of biorefractory species, etc., to achieve recycling, improve oxidative decomposition efficiency, save energy The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

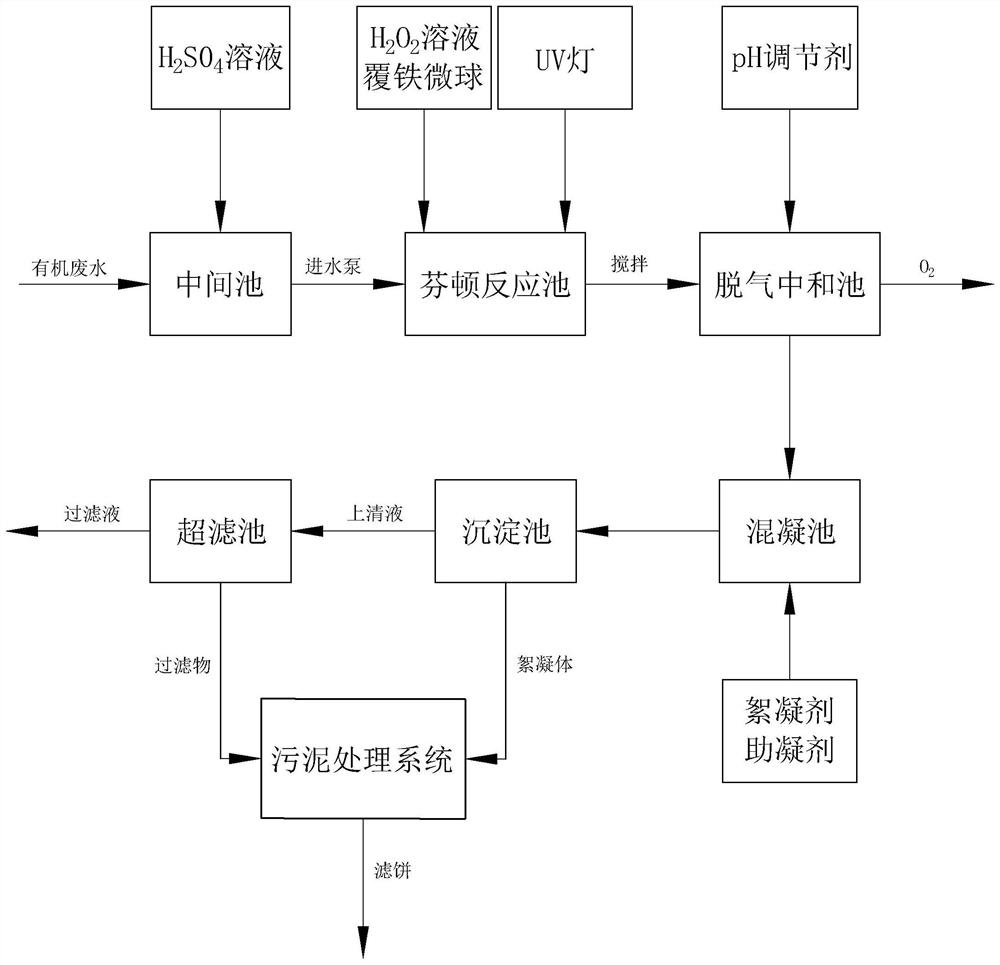

Method used

Image

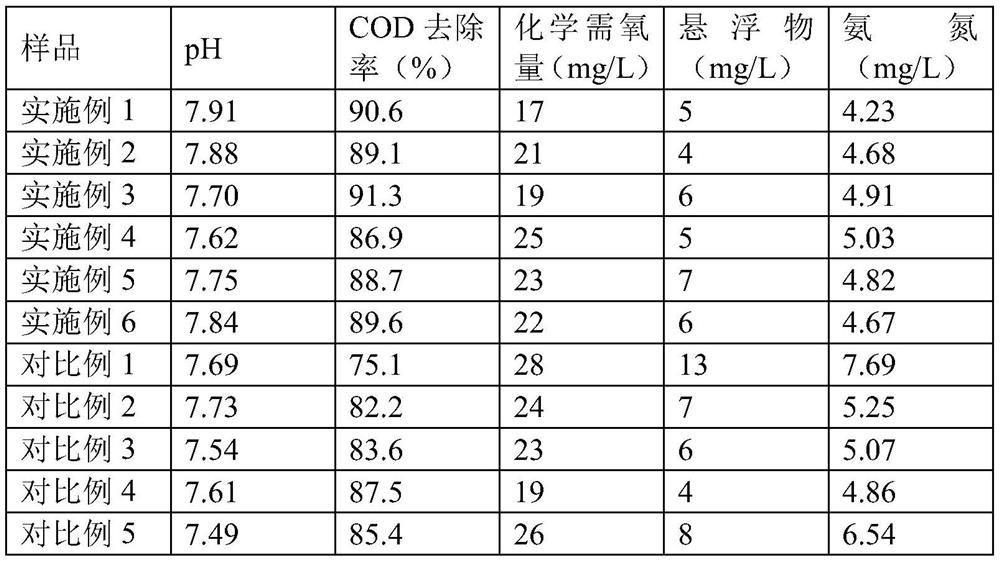

Examples

Embodiment 1

[0037] Embodiment 1 is a UV-FENTON wastewater treatment process disclosed by the present invention, which specifically includes the following steps: S1. Intermediate pool: organic wastewater enters the intermediate pool, and H is added to the intermediate pool through the dosing system. 2 SO 4 The solution adjusts the pH value of the wastewater to 3.2, and then feeds the organic wastewater into the Fenton reaction tank through the inlet pump;

[0038] S2. Fenton reaction cell: add H to the Fenton reaction cell through the dosing system 2 o 2 solution and iron-coated microspheres, H 2 o 2 with Fe 2+ The molar ratio is 4:1, and the UV light is turned on to increase the UV light irradiation, so that the organic matter can fully react and decompose in the Fenton reaction tank, and the residence time of organic wastewater in the Fenton reaction tank is 1h; the iron-coated microspheres are formed by lipid compound, the surface is covered with FeSO 4 Powder, embedded with coppe...

Embodiment 2

[0043] Embodiment 2 is a kind of UV-FENTON wastewater treatment process disclosed by the present invention, which specifically includes the following steps: S1. Intermediate pool: organic wastewater enters the intermediate pool, and H is added to the intermediate pool through the dosing system. 2 SO 4 The solution adjusts the pH value of the wastewater to 3.2, and then feeds the organic wastewater into the Fenton reaction tank through the inlet pump;

[0044] S2. Fenton reaction cell: add H to the Fenton reaction cell through the dosing system 2 o 2 solution and iron-coated microspheres, H 2 o 2 with Fe 2+ The molar ratio is 3:1, and the UV lamp is turned on to increase the UV light irradiation, so that the organic matter can fully react and decompose in the Fenton reaction tank, and the residence time of the organic wastewater in the Fenton reaction tank is 1h; the iron-coated microspheres are formed by lipid compound, the surface is covered with FeSO 4 Powder, embedded...

Embodiment 3

[0049] Embodiment 3 is a kind of UV-FENTON wastewater treatment process disclosed by the present invention, specifically comprising the following steps:

[0050] S1. Intermediate pool: Organic wastewater enters the intermediate pool, and H is added to the intermediate pool through the dosing system 2 SO 4 The solution adjusts the pH value of the wastewater to 3.2, and then feeds the organic wastewater into the Fenton reaction tank through the inlet pump;

[0051] S2. Fenton reaction cell: add H to the Fenton reaction cell through the dosing system 2 o 2 solution and iron-coated microspheres, H 2 o 2 with Fe 2+ The molar ratio is 5:1, and the UV light is turned on, and the UV light irradiation is increased, so that the organic matter can fully react and decompose in the Fenton reaction tank, and the residence time of the organic wastewater in the Fenton reaction tank is 1h; the iron-coated microspheres are formed by lipid compound, the surface is covered with FeSO 4 Powd...

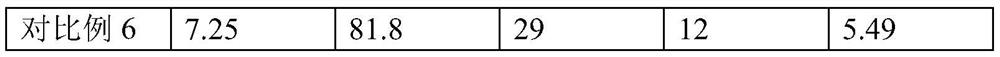

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com