Anti-icing hydrogel bonding material as well as preparation method and application thereof

A technology for bonding materials and ice water, applied in chemical instruments and methods, and other chemical processes, can solve the problems of irreversible bonding, inability to resist ice and anti-ice hydrogel, etc., and achieve easy large-scale production and universal The effect of adaptability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

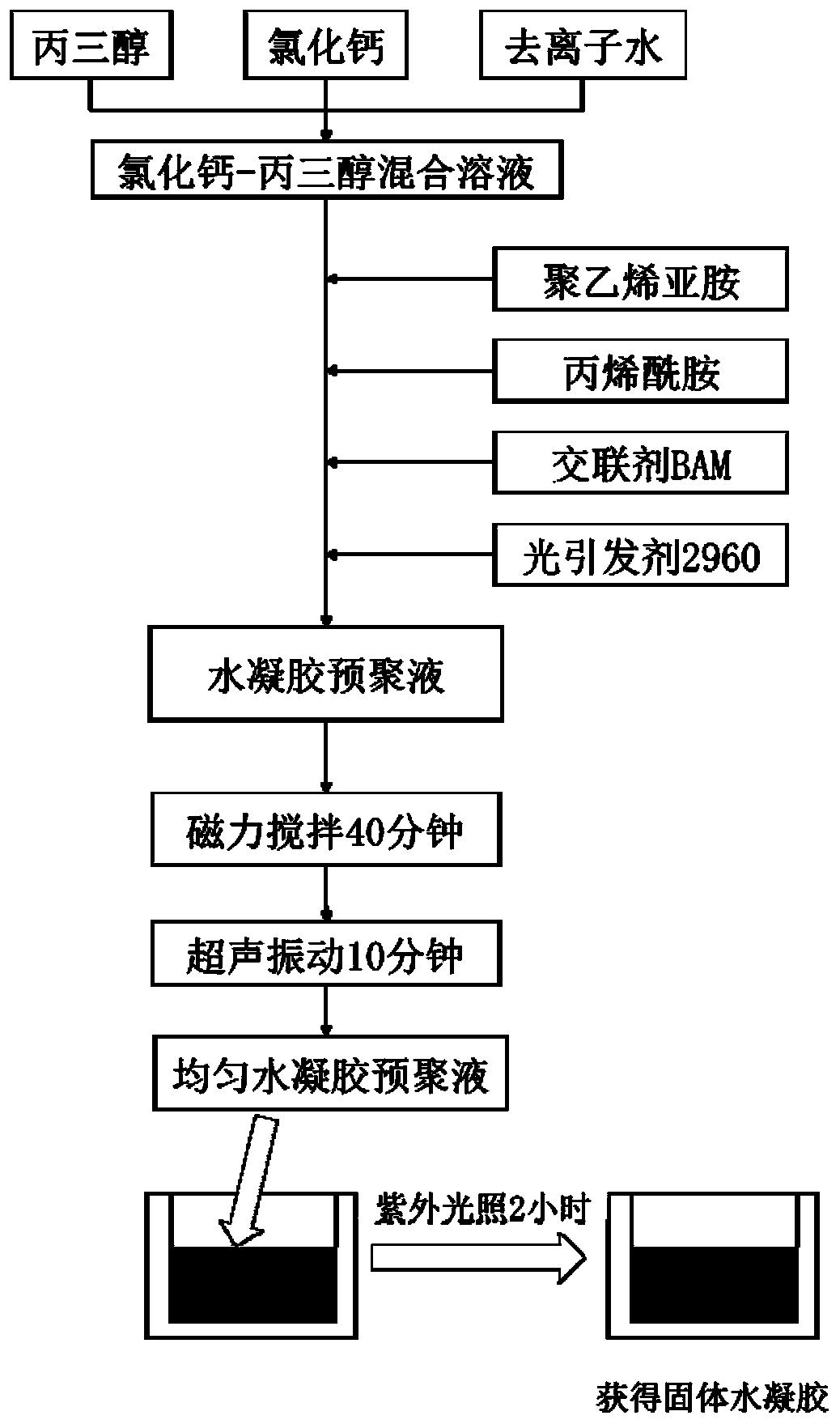

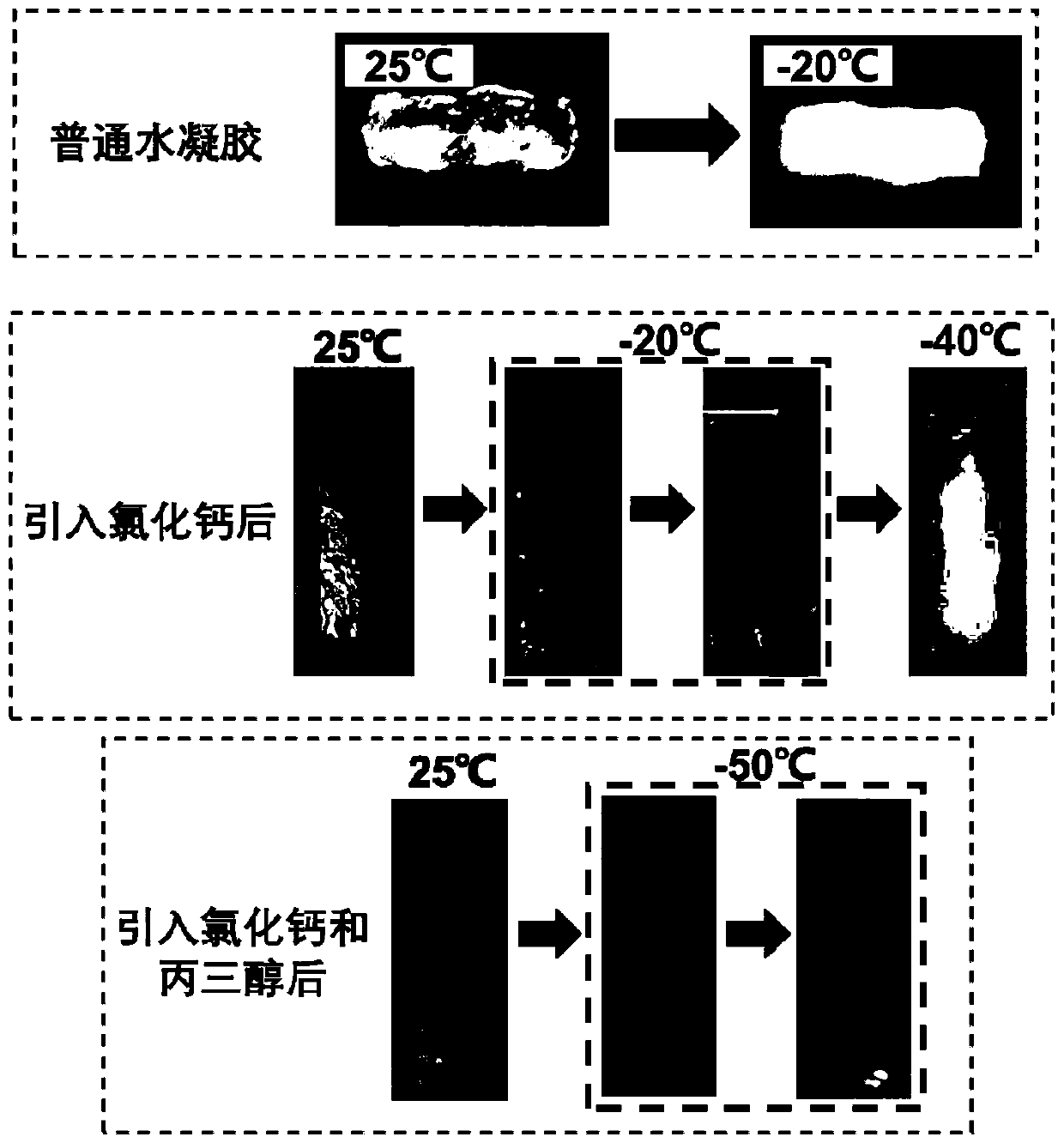

[0043] The present invention also provides the preparation method of this ice-resistant hydrogel adhesive material, such as figure 1 Shown, described preparation method comprises the following steps:

[0044] (1) glycerol and calcium chloride are dissolved in deionized water to make calcium chloride-glycerol mixed solution;

[0045] (2) Polyethyleneimine, acrylamide, cross-linking agent N, N-methylenebisacrylamide (BAM) and photoinitiator 2960 are dissolved in the calcium chloride-glycerol mixed solution to make a hydraulic gel Glue prepolymer solution;

[0046] (3) Stir the hydrogel pre-polymerization liquid for 40 minutes by magnetic force and ultrasonically stir for 10 minutes to obtain a uniform hydrogel pre-polymerization liquid;

[0047] (4) Pour the uniform hydrogel pre-polymerization solution into a mold, and irradiate with ultraviolet rays for 2 hours to obtain the solid ice-resistant hydrogel bonding material.

[0048] In the step (1), the selected ratio of water an...

Embodiment 1

[0056] 21.62 g of glycerol and 7.57 g of calcium chloride were dissolved in 9.81 g of deionized water to prepare a calcium chloride-glycerol solution. Then add 9g of acrylamide monomer, 2g of 50% PEI aqueous solution (containing 1g of PEI, which is a branched chain polymer with a molecular weight of 70000), 0.0054g of N,N-methylenebisacrylamide and 0.18g of photoinitiator 2960 made of hydrogel pre-polymerization liquid. Then magnetic stirring for 40 minutes and ultrasonic stirring for 10 minutes to obtain a uniform hydrogel pre-polymerization solution. Pour the uniform hydrogel pre-polymerization solution into a mold, and irradiate it with ultraviolet rays with a wavelength of 365nm and a power of 8W for 2 hours to obtain a hydrogel solid.

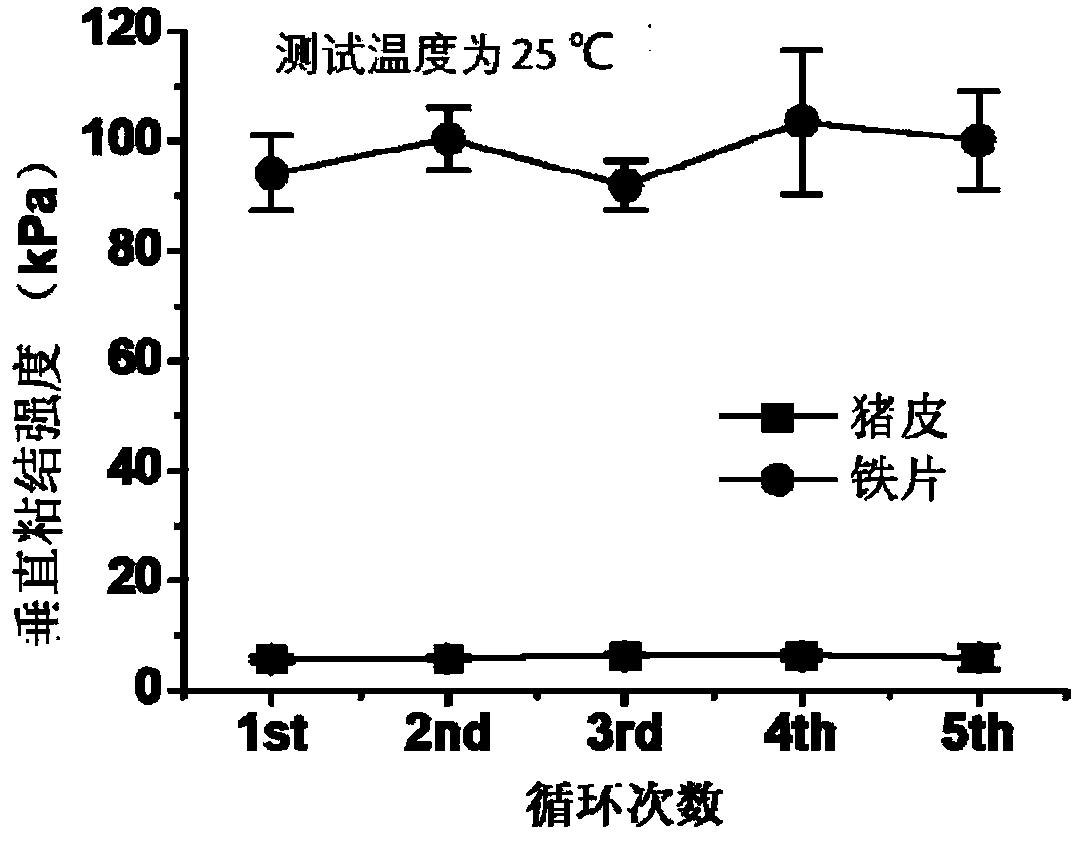

[0057] Taking iron as a test sample, this example is used to conduct a vertical bond test at room temperature (25° C.), and the measured bond strength is 90-100 kPa.

[0058] image 3 It is the cycle test result of the ice-resistant hyd...

Embodiment 2

[0064] 21.62 g of glycerol and 7.57 g of calcium chloride were dissolved in 10.56 g of deionized water to prepare a calcium chloride-glycerol solution. Then add 9.75g of acrylamide monomer, 0.5g of 50% PEI aqueous solution (containing 0.25g of PEI, which is a branched polymer with a molecular weight of 70000), 0.00585g of N,N-methylenebisacrylamide and 0.195g Photoinitiator 2960 is used to make hydrogel prepolymerization solution. Then magnetic stirring for 40 minutes and ultrasonic stirring for 10 minutes to obtain a uniform hydrogel pre-polymerization liquid. Pour the uniform hydrogel pre-polymerization solution into a mold, and irradiate it with ultraviolet rays with a wavelength of 365nm and a power of 8W for 2 hours to obtain a hydrogel solid.

[0065] Taking iron as a test sample, this example is used to conduct a vertical bond test at room temperature (25° C.), and the measured bond strength is 85-90 kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com