3D printing polyimide aerogel and preparation method thereof

A technology for printing polyimide and 3D printing, which can be used in processing and manufacturing, liquid material additive processing, additive processing, etc., and can solve the problems of environmental pollution, long time, and impure polyimide aerogel. To achieve the effect of simple synthesis process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

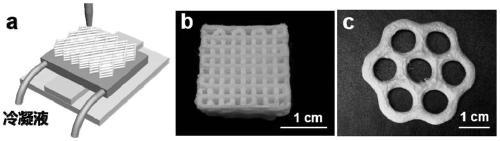

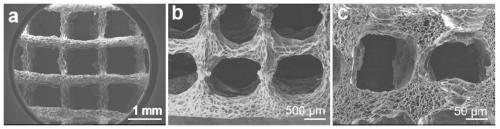

[0042] (1) Using N,N-dimethylacetamide as a solvent, add 4,4'-diaminodiphenyl ether and pyromellitic anhydride in an ice-water bath for condensation polymerization in an equimolar ratio to prepare a solid content 15% polyamic acid. The specific process is as follows: Dissolve 8.0096g of 4,4'-diaminodiphenyl ether in 95.57g of N,N-dimethylacetamide, add 8.86g of pyromellitic anhydride, and react in an ice-water bath for 5h. Then, 4.0476 g of triethylamine was added, and the reaction was continued for 3 hours to prepare a water-soluble polyamic acid solution with a solid content of 15%. The prepared water-soluble polyamic acid is precipitated with deionized water, and then washed and freeze-dried to obtain a dry silk of the water-soluble polyamic acid for use.

[0043] (2) Dissolve 1 g of polyamic acid dry silk in 12.5 mL of deionized water, add 0.5 g of triethylamine, put it on a magnet and stir on a stirring table for 12 hours to obtain a polyamic acid sol with a solid conten...

Embodiment 2

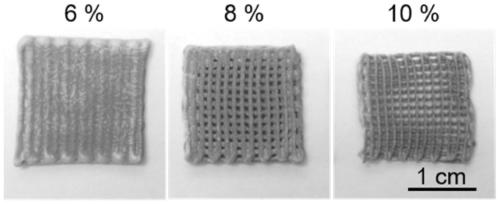

[0047] Change the amount of deionized water in Example 1 to 16.6mL to prepare a polyamic acid solution with a solid content of 6%. The freeze-solidified polyamic acid with a three-dimensional framework structure obtained through cold plate-assisted 3D printing is denoted as PAA-6. The obtained polyimide airgel with a three-dimensional framework structure is designated as PI-6, and the rest are the same as in Example 1.

Embodiment 3

[0049] Change the amount of deionized water in Example 1 to 10mL to prepare a polyamic acid solution with a solid content of 10%. The freeze-solidified polyamic acid with a three-dimensional framework structure obtained by cold plate-assisted 3D printing is denoted as PAA -10. The obtained polyimide airgel with a three-dimensional framework structure is designated as PI-10, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com