A kind of preparation method of modified polybutyrolactam

A technology for polybutyrolactam and butyrolactam, which is applied in the field of materials, can solve the problems of a wide variety of additives, complicated preparation processes, impure products, etc., and achieves the effects of wide production and application prospects, simple operation, and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of modified polybutyrolactam, concrete steps are as follows:

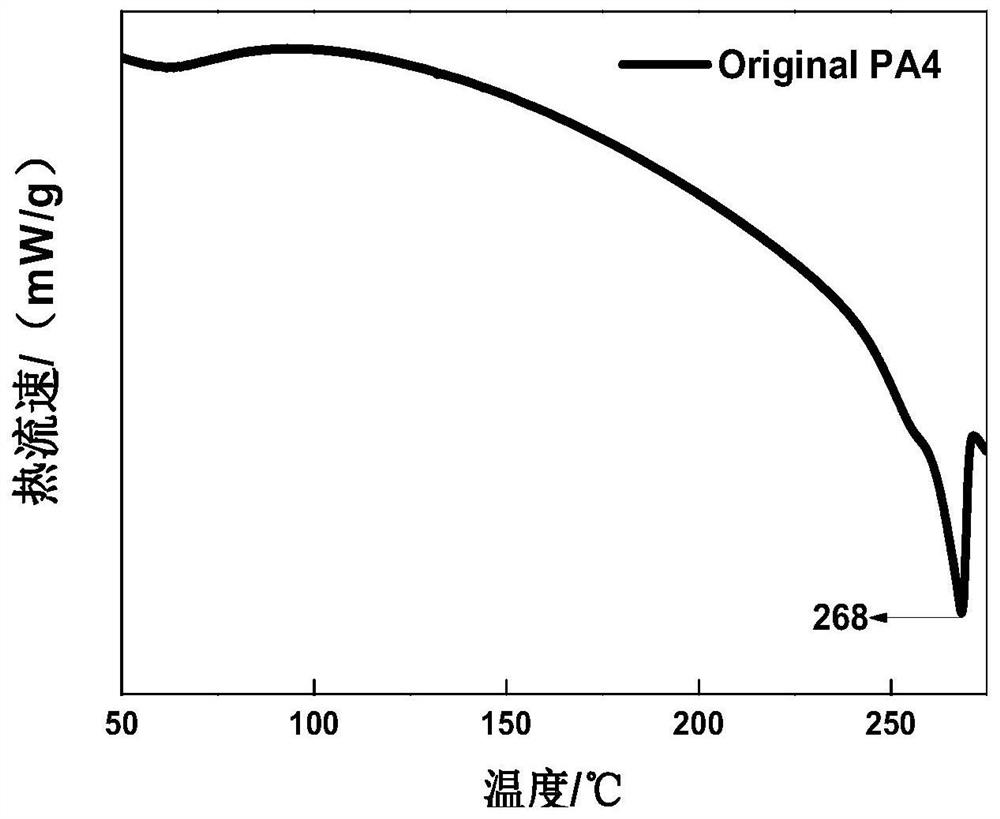

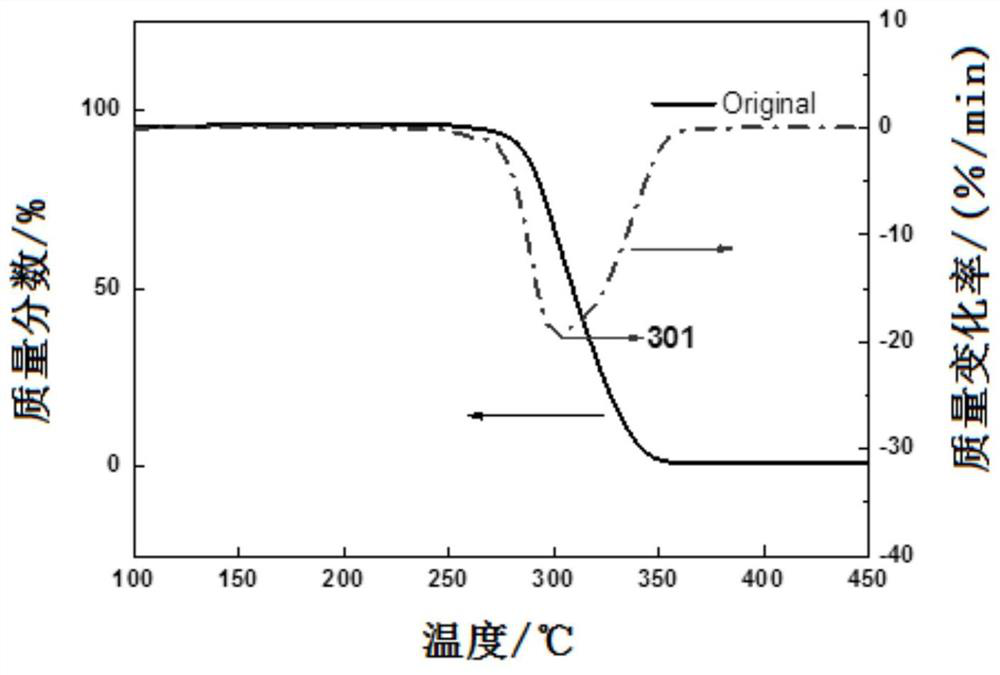

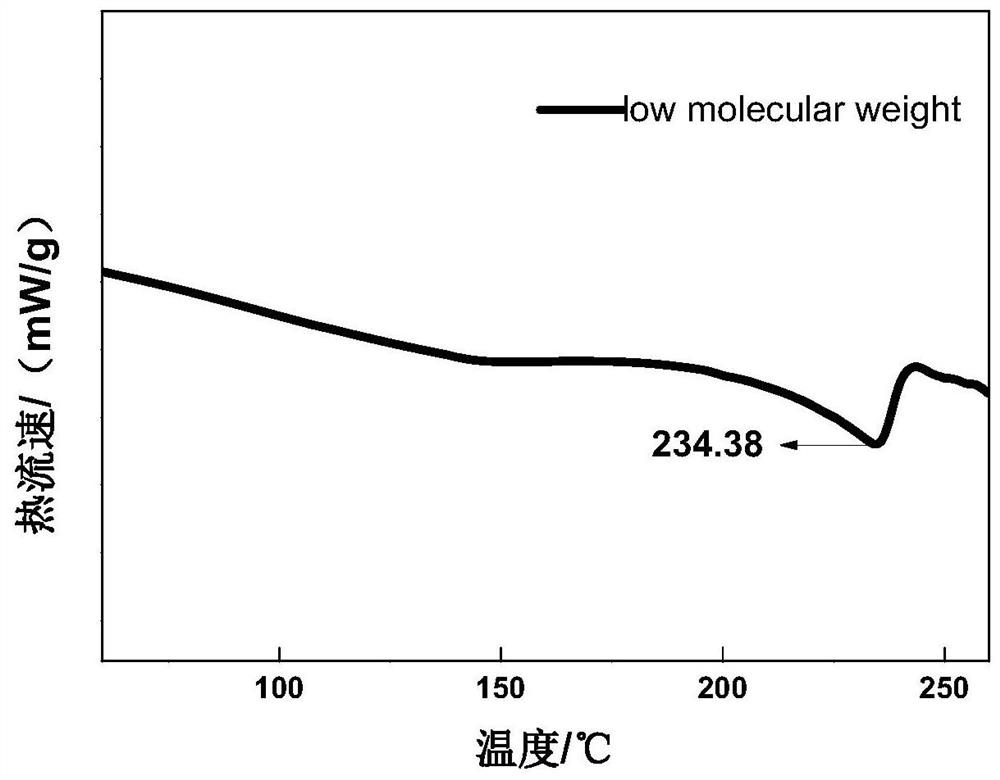

[0036] (1) Preparation of raw materials: prepare high-molecular-weight linear polybutyrolactam and low-molecular-weight branched polybutyrolactam, wherein the viscosity-average molecular weight of high-molecular-weight linear polybutyrolactam is 2.0×10 4 -6.0×10 4 g / mol; the viscosity-average molecular weight of low molecular weight branched polybutyrolactam is 0.1×10 4 -1.5×10 4 g / mol;

[0037] (1-1) High molecular weight linear polybutyrolactam is prepared by the following method: at 70-120°C, butyrolactam is reacted with a catalyst, including but not limited to potassium tert-butoxide, sodium hydroxide, potassium hydroxide, carbonic acid When the temperature of potassium, sodium carbonate, and activated butyrolactam is lowered to 30-60°C, add an initiator, including but not limited to benzoyl chloride, fumaryl chloride, acetic anhydride, and isocyanate, and react for 8-48 h...

Embodiment 1

[0056] 1. The modification method of polybutyrolactam thermal performance comprises the following steps:

[0057] (1) Preparation of raw materials: Synthesis of high molecular weight linear polybutyrolactam: at 90°C, 50g of butyrolactam was reacted with 2.64g of potassium tert-butoxide for 2 hours, and when the temperature was lowered to 40°C, 1.34ml of benzoyl chloride was added As an initiator, react for 24h to obtain a molecular weight of 4.0×10 4 g / mol linear polybutyrolactam; synthesis of low molecular weight branched polybutyrolactam: at 90°C, 50g butyrolactam was reacted with 4.6g potassium tert-butoxide for 2h, and when the temperature was lowered to 40°C, 1.05 ml1,3,5-benzenetricarbonyl chloride was used as an initiator, and reacted for 2 hours to obtain a molecular weight of 0.2×10 4 g / mol of three-branched polybutyrolactam.

[0058] (2) Mixing of two kinds of structure polybutyrolactam: high molecular weight linear polybutyrolactam and low molecular weight branche...

Embodiment 2

[0063] 1. The modification method of polybutyrolactam thermal performance comprises the following steps:

[0064] (1) Preparation of raw materials: Synthesis of high molecular weight linear polybutyrolactam: at 90°C, 50g of butyrolactam was reacted with 2.64g of potassium tert-butoxide for 2 hours, and when the temperature was lowered to 40°C, 1.34ml of benzoyl chloride was added As an initiator, react for 24h to obtain a molecular weight of 4.0×10 4 g / mol linear polybutyrolactam; synthesis of low molecular weight branched polybutyrolactam: at 90°C, 50g butyrolactam was reacted with 4.6g potassium tert-butoxide for 2h, and when the temperature was lowered to 40°C, 1.05 ml1,3,5-benzenetricarboxylic acid chloride was used as the initiator, and the reaction was carried out for 6 hours to obtain a molecular weight of 0.6×10 4 g / mol of three-branched polybutyrolactam.

[0065] (2) Mixing of two kinds of structure polybutyrolactam: high molecular weight linear polybutyrolactam and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com