Controllable electromagnetic drive type impact-scraping and cutting composite drill bit and method

An electromagnetic drive, composite drill bit technology, applied in drill bits, electric components, driving devices for drilling in wellbore, etc., can solve the problems of low rock breaking efficiency, reduced drill bit ROP, low ROP, etc., to reduce the difficulty And the effect of rock breaking energy consumption, thermal wear phenomenon improvement, and simple impact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with embodiment the present invention is further described.

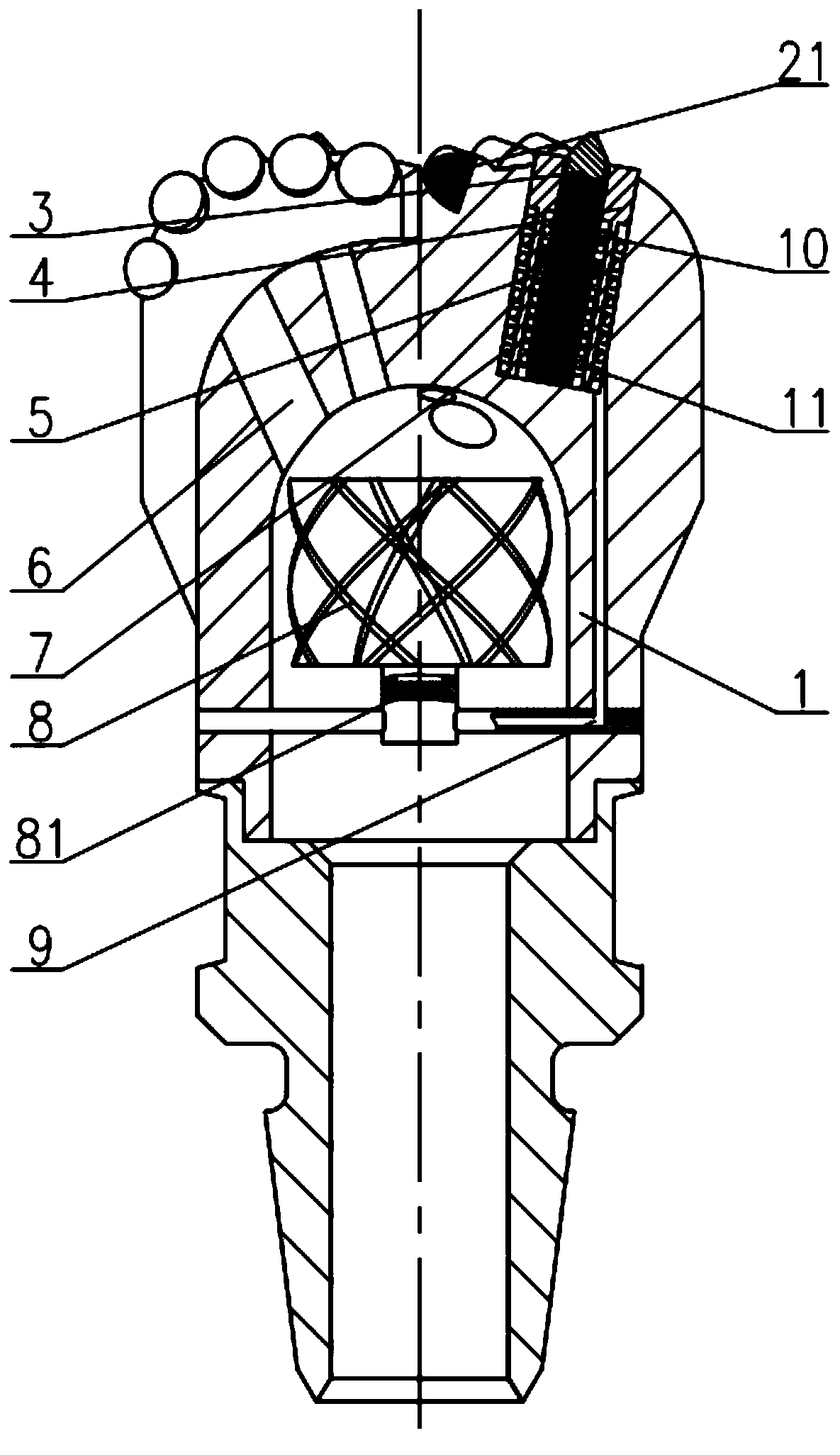

[0069] A controllable electromagnetic-driven impact-scraping composite drill bit, which can realize automatic power supply and energy storage at the bottom of the well, reduce the use of transmission parts to improve the reliability of the drill bit, and can apply frequency-controllable force to the rock during the drilling process of the PDC bit. Shock load, improve rock breaking efficiency and prolong the life of downhole drilling tools.

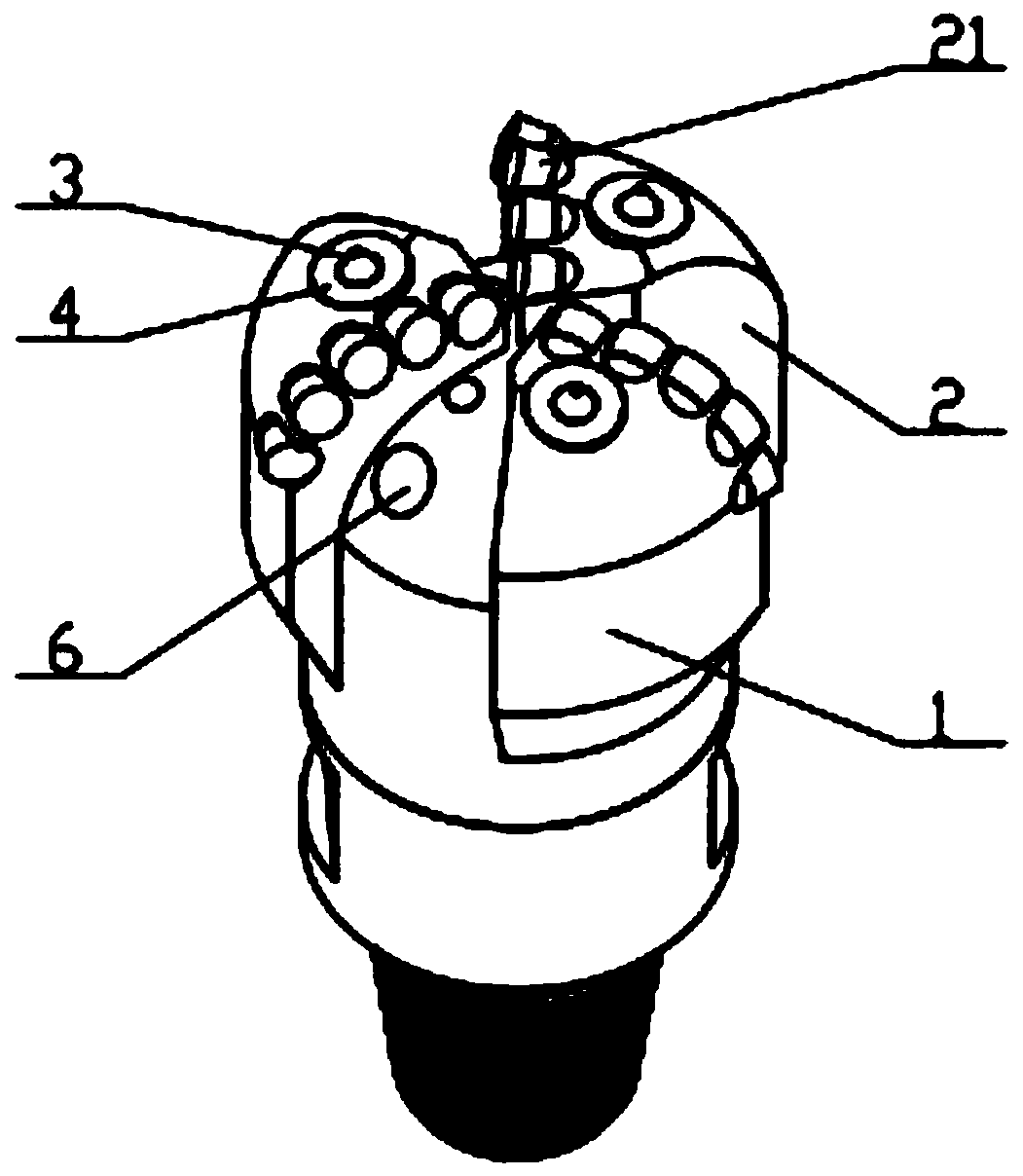

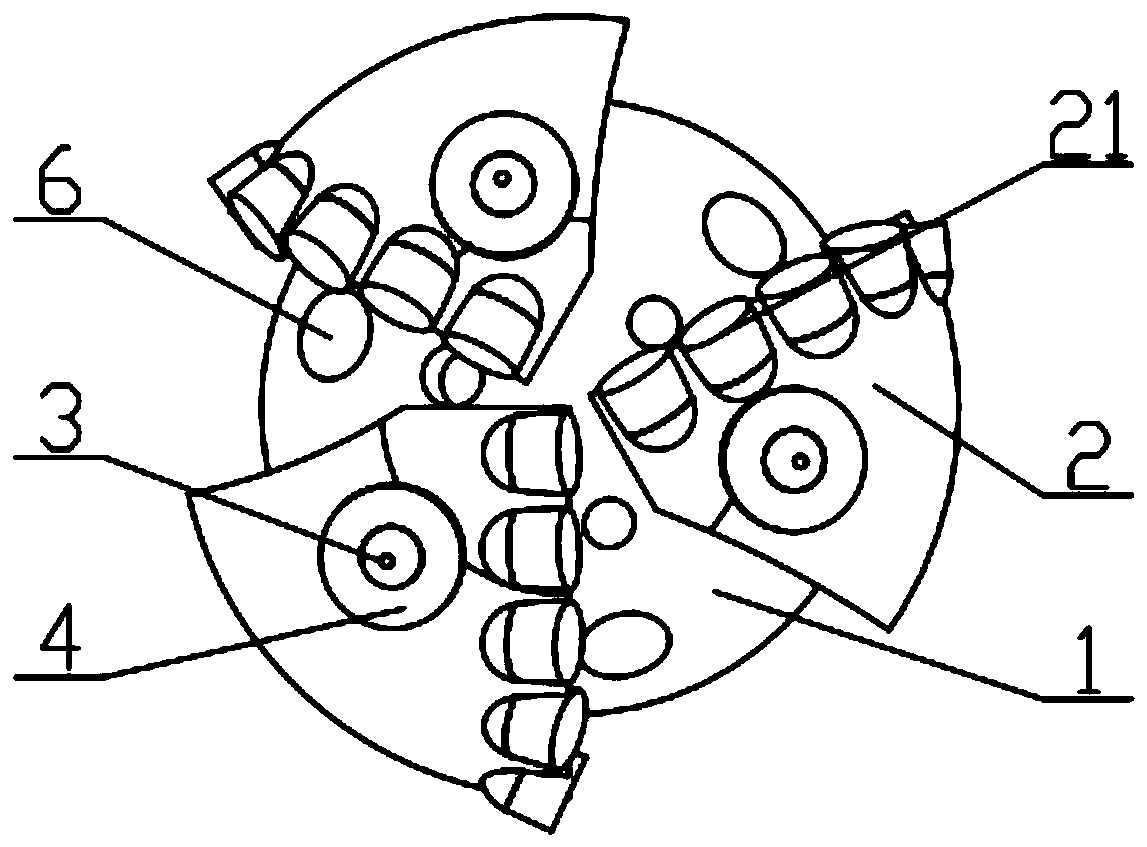

[0070] Such as Figure 1-10 As shown, a controllable electromagnetic-driven impact-scraping composite drill bit includes a drill body 1 and a fixed cutting structure fixed on the drill body 1. The composite drill bit is provided with an impact cutting structure and a power supply energy storage structure. The drill bit includes a drill body 1, a blade 2 extending from the drill body 1, a water channel between the blades 2, a water hole 6 or a nozzle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com