High-pressure gas-liquid linkage device for rapidly closing spiral rotating oil cylinder

A rotary oil cylinder and fast closing technology, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of slow fast closing action, failure to meet technical requirements, lack of redundant configuration, etc., and achieve reduction The leakage point, the overall structure is simple and beautiful, and the effect of simplifying the connection of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

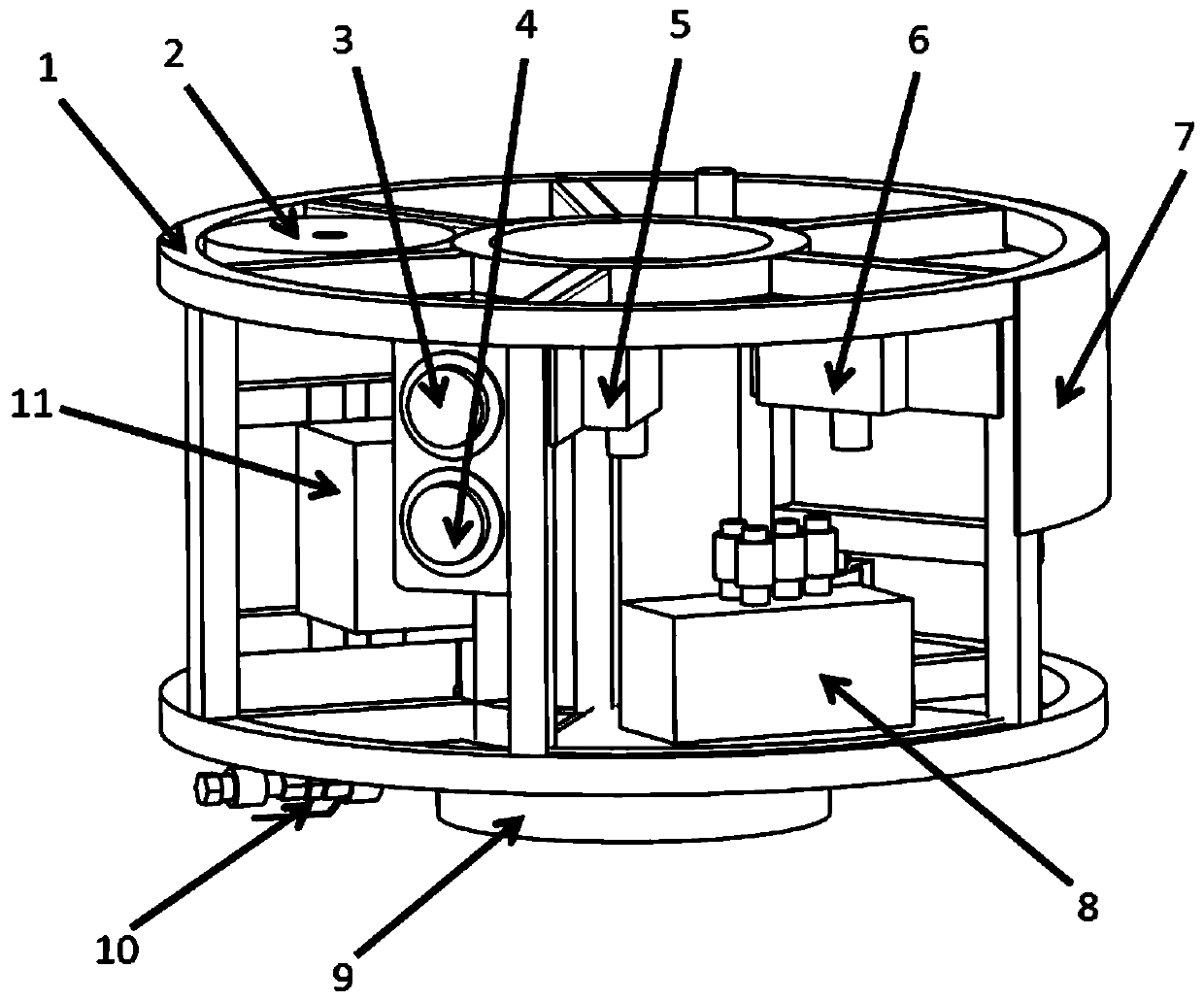

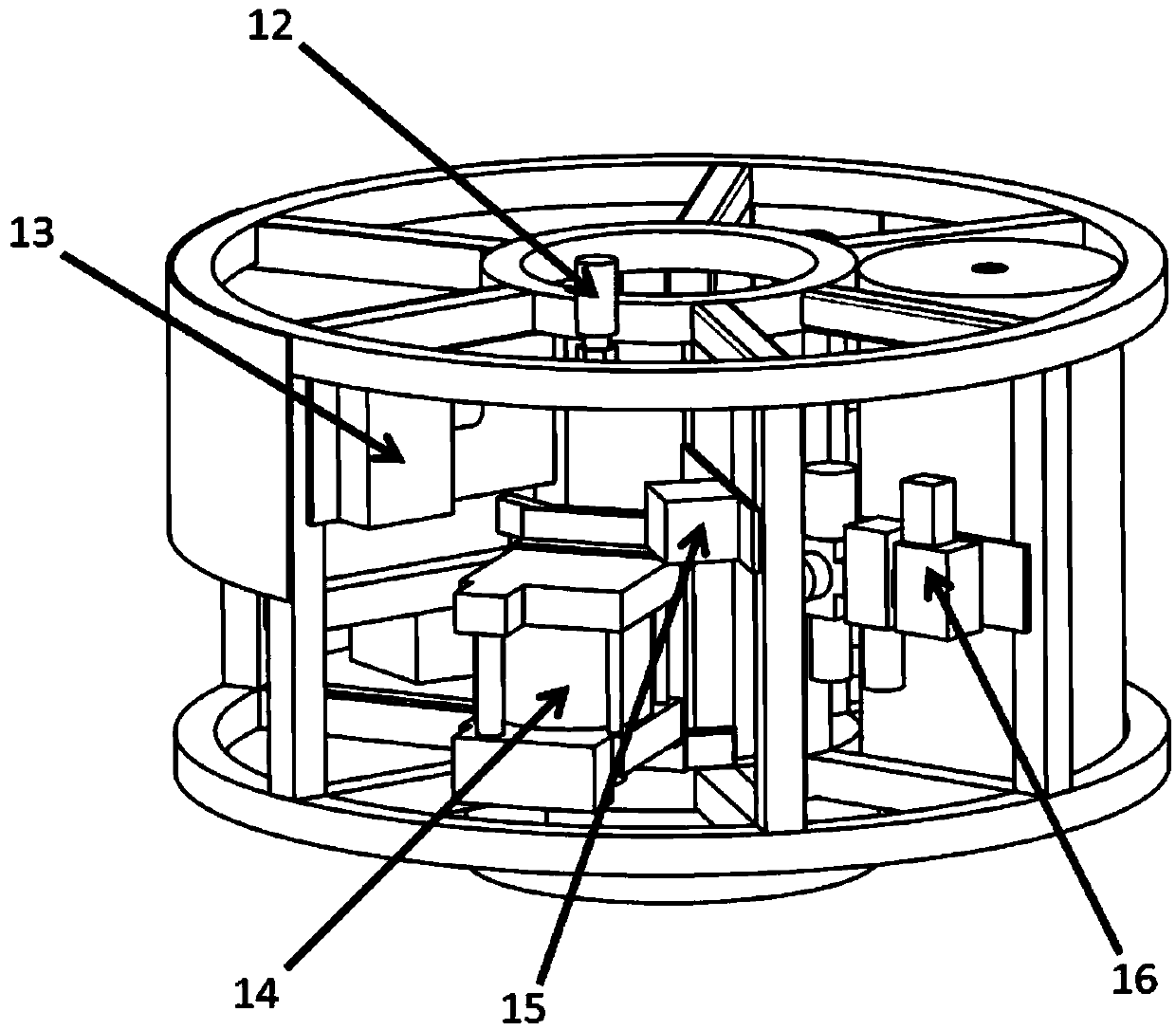

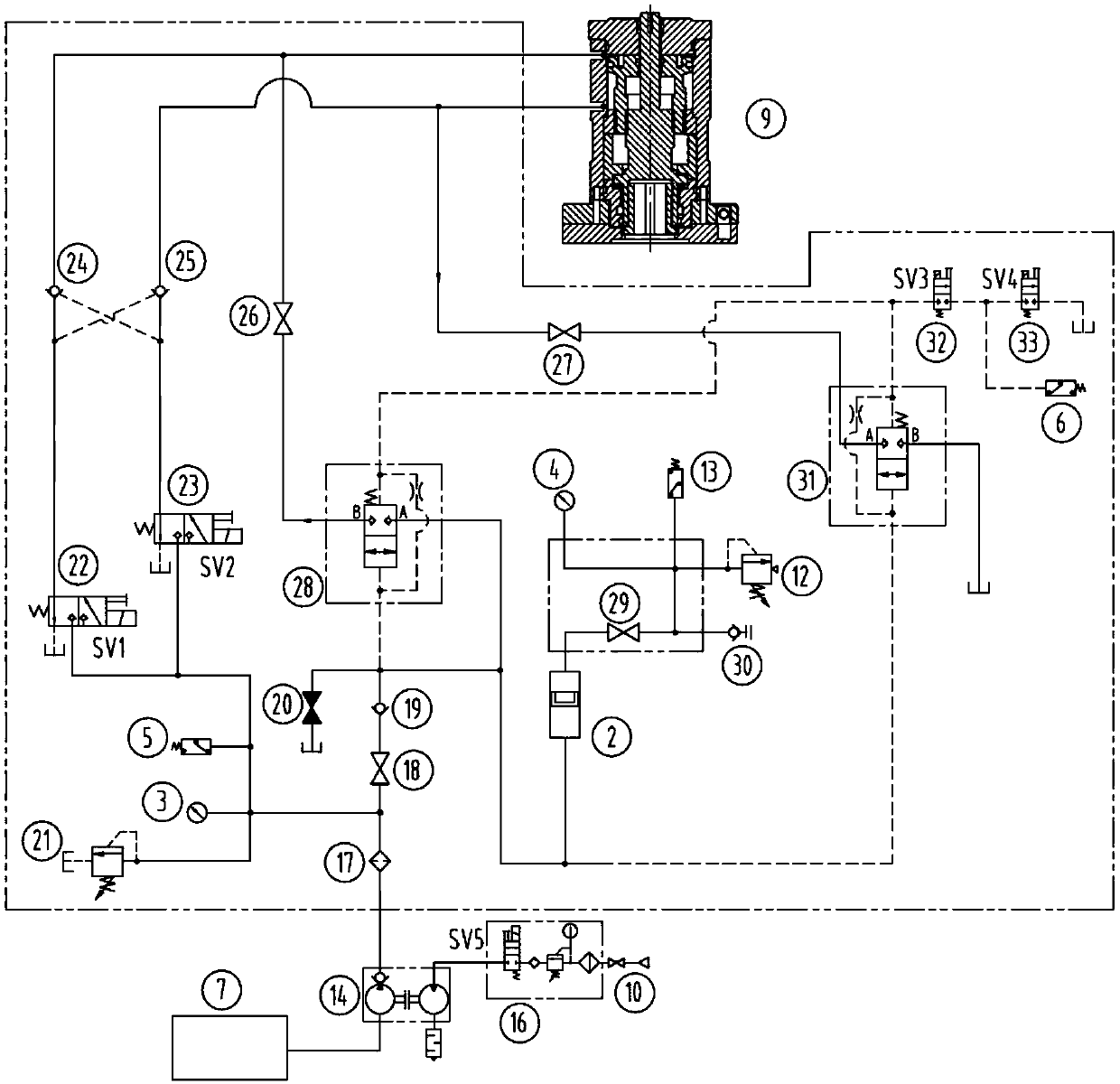

[0031] The core components of the helical rotary cylinder quickly closing the high-pressure gas-hydraulic linkage device are installed on the frame structure 1, such as figure 1 A schematic diagram of the installation of each component is given.

[0032] The upper and lower ends of the frame structure 1 are ring-shaped flanges, and vertical installation ribs are installed between the upper and lower flanges to evenly divide the space between the flanges and facilitate the installation of various components.

[0033] Among them, the piston accumulator 2 is installed on the upper flange, the oil pressure gauge 3 and the nitrogen pressure gauge 4 are installed through ribs, and are located between the upper and lower flanges, and the pressure switch A5 and pressure switch B6 are installed under the lower flange On the surface, while the oil tank 5 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com