High-nickel ternary positive electrode material and preparation method thereof

A positive electrode material, high-nickel technology, applied in the field of high-nickel ternary positive electrode material and its preparation, to achieve the effects of improving cycle stability, preventing dissolution, and good first-time discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Another aspect of the present invention provides a method for preparing a high-nickel ternary positive electrode material, preferably a method for preparing the high-nickel ternary positive electrode material described in the first aspect of the present invention, the method comprising the following steps:

[0064] Step 1, mixing high-nickel ternary precursor, lithium source and dopant;

[0065] According to the present invention, in step 1, the high-nickel ternary precursor is a nickel-cobalt-manganese ternary precursor, preferably one or more selected from hydroxides, oxides and carbonates of nickel-cobalt-manganese.

[0066] According to the present invention, in step 1, the high-nickel ternary precursor is the hydroxide of nickel-cobalt-manganese, preferably by formula Ni x co y mn 1-x-y (OH) 2 The hydroxide represented by, among them, 0.8≤x≤0.95, 00.88 co 0.08 mn 0.04 (OH) 2 .

[0067] In the present invention, the source of the high-nickel ternary precursor...

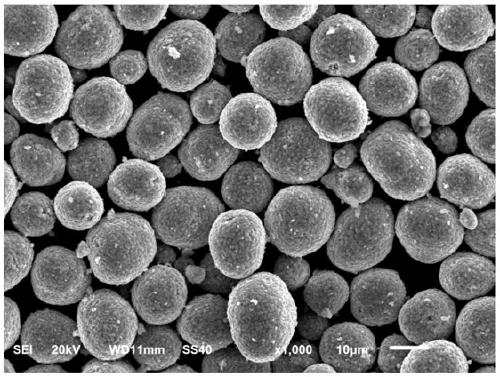

Embodiment 1

[0116] Weigh 200g of Ni with a particle size of 10-20μm 0.88 co 0.08 mn 0.04 (OH) 2 Precursor, 96.595g LiOH·H 2 O, 0.526gZrO 2 and 0.1703g TiO 2 In a blender, mix the four powders evenly;

[0117] The mixed powder was put into a crucible, and sintered once in a box furnace, and the heating rate was controlled to be 5°C / min, and the calcination was carried out under an oxygen atmosphere of 820°C and kept for 12h. Then cool down to room temperature naturally, crush, sieve, and evenly refine the powder, then mix 100g of the obtained material with 100g of deionized water, stir rapidly for 10min, then filter and dry;

[0118] Take the dried sample 100g and 0.5g B 2 o 3 Coating materials are uniformly mixed,

[0119] Then put it into a box-type furnace for secondary sintering, control the heating rate to 3°C / min, carry out calcination under 300°C oxygen atmosphere and keep it warm for 6h. Then it is naturally lowered to room temperature, crushed and sieved to obtain a high...

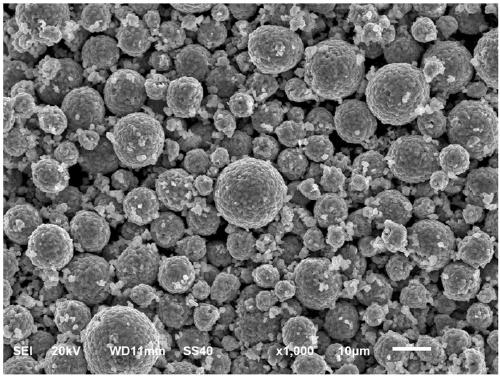

Embodiment 2

[0123] Weigh 100g of Ni with a particle size of 10-20μm 0.88 co 0.08 mn 0.04 (OH) 2 , 100g of Ni with a particle size of 3-6μm 0.88 co 0.08 mn 0.04 (OH) 2 Precursor, 47.272g LiOH·H 2 O, 0.263gZrO 2 and 0.086g MgO in a stirrer to mix the four powders evenly;

[0124] Put the mixed powder into a crucible and sinter in a box furnace at a rate of 4°C / min. Calcination is carried out under an oxygen atmosphere of 800°C and kept for 10 hours, then it is naturally lowered to room temperature and crushed. Sieve to make the powder evenly refined, then mix 70g of the obtained material with 70g of deionized water, stir rapidly for 12min, then filter and dry;

[0125] Take the sample 60g after drying and Al 2 o 3 Coating material 0.18g is mixed evenly;

[0126] Then put it into a box-type furnace for secondary sintering, control the heating rate to 4°C / min, and carry out calcination under an oxygen atmosphere of 700°C and keep it for 7h. Then it is naturally lowered to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com