Motor controller and method and system for adaptively changing IBGT gate-level resistance value of motor controller

A motor controller and resistance value technology, applied in control systems, AC motor control, high-efficiency power electronic conversion, etc., can solve the problems of reducing IGBT operation risk, increasing IGBT turn-off time, and large IGBT loss, and improving electronic control. Power density, the effect of avoiding too small gate-level circuit and avoiding too large gate-level resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0062] As a preferred implementation, the electrical switch includes a MOS tube.

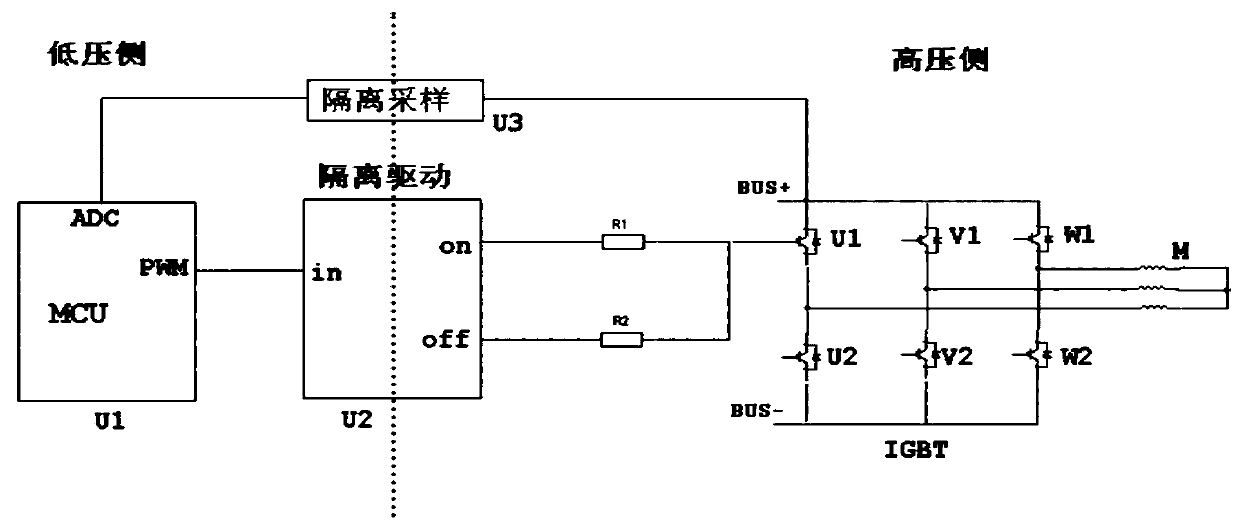

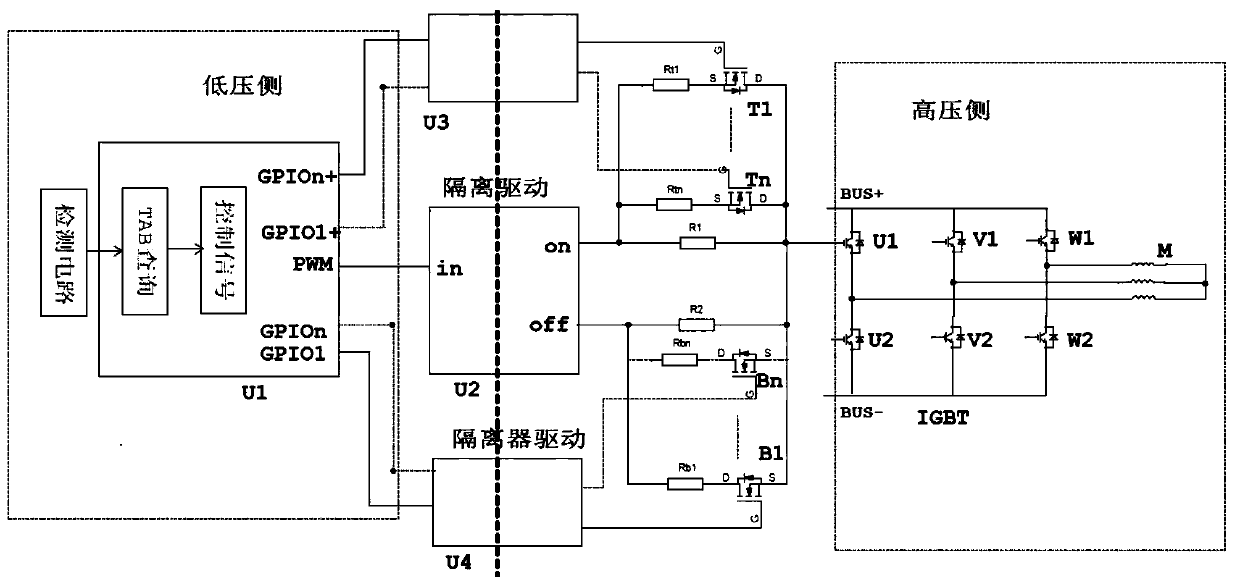

[0063] When the above system is applied to the motor drive process, the corresponding drive circuit includes: a low-voltage side circuit and a high-voltage side circuit, wherein the low-voltage side circuit and the high-voltage side circuit are isolated by an isolator, specifically, as image 3 Shown:

[0064] The low-voltage side includes: detection circuit, control unit U1 ( image 3 The functions are expressed as "TAB query module" and "control signal module"), wherein the detection circuit is used to detect the current working conditions of the motor controller (bus voltage, ambient temperature, etc., among which, the bus voltage detection is the use of resistor divider The principle detects the voltage value between BUS+ and BUS-; the ambient temperature is sensed or detected by NTC thermistor); the TAB query module determines the corresponding optimal gate-level resistance value according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com