Carbon-based adsorbent for mercury removal as well as preparation method and application thereof

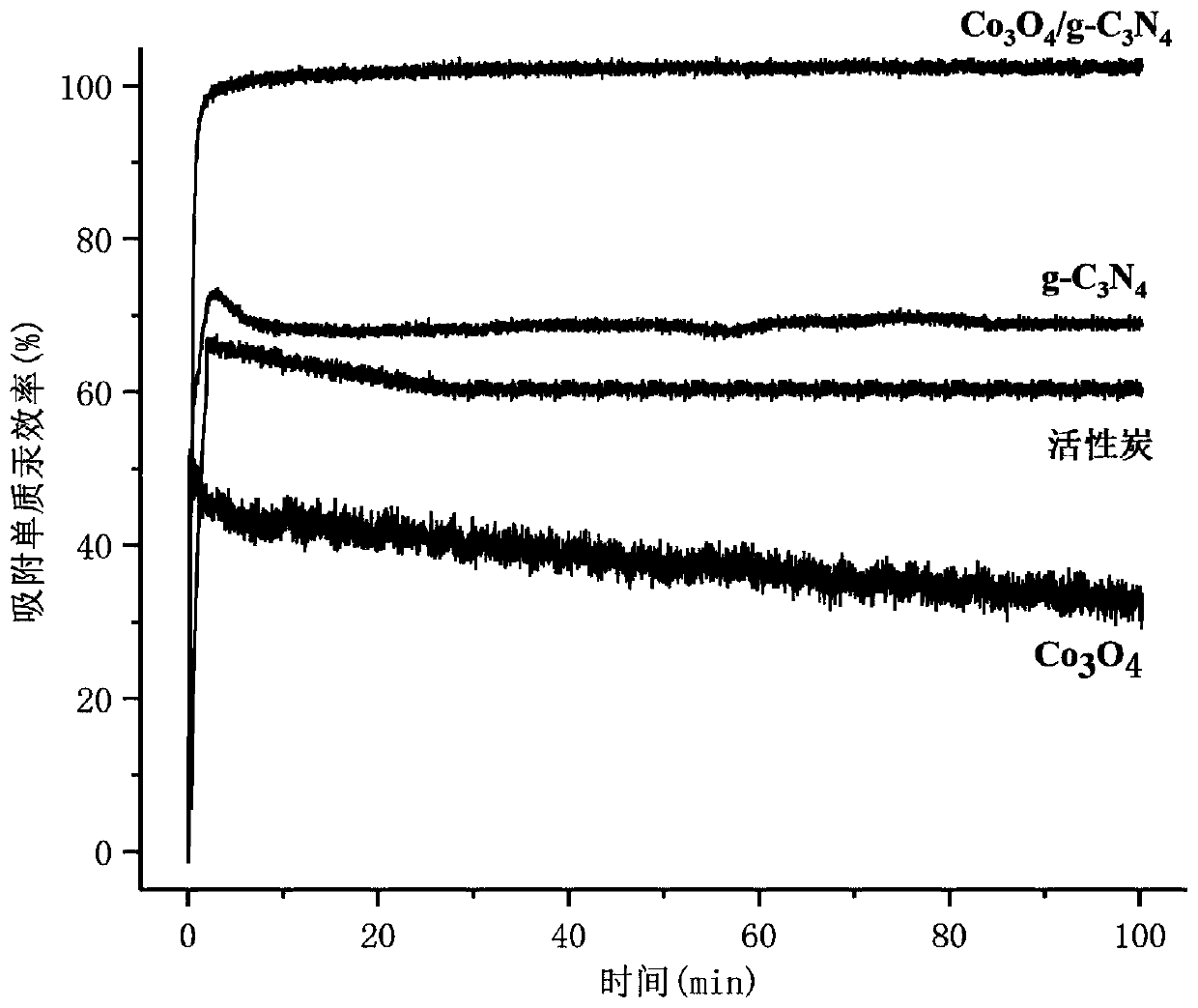

An adsorbent, carbon-based technology, applied in the field of materials, can solve the problems of poor mercury removal efficiency and high operating cost of adsorbents, and achieve the effects of broad specific surface area and active sites, good adsorption performance, and low environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A carbon-based adsorbent for mercury removal, obtained by a preparation method comprising the following steps:

[0034] Preparation of graphite-phase carbon nitride: (1) Weigh 5 g of melamine at room temperature and place it in a cylindrical crucible, place the crucible in a muffle furnace, set the heating rate at 10°C / min to 500°C, and calcinate for 3 hours, After it was naturally cooled to room temperature, the crucible was taken out, and the bulk solid obtained by calcination was recorded as B, and B was fully ground in an agate mortar.

[0035] (2) Put B in a crucible, heat up to 500°C at a heating rate of 10°C / min, calcinate for 4 hours, and cool naturally to room temperature to obtain graphitic carbon nitride C. The specific surface area of graphitic carbon nitride C is 110m 2 / g.

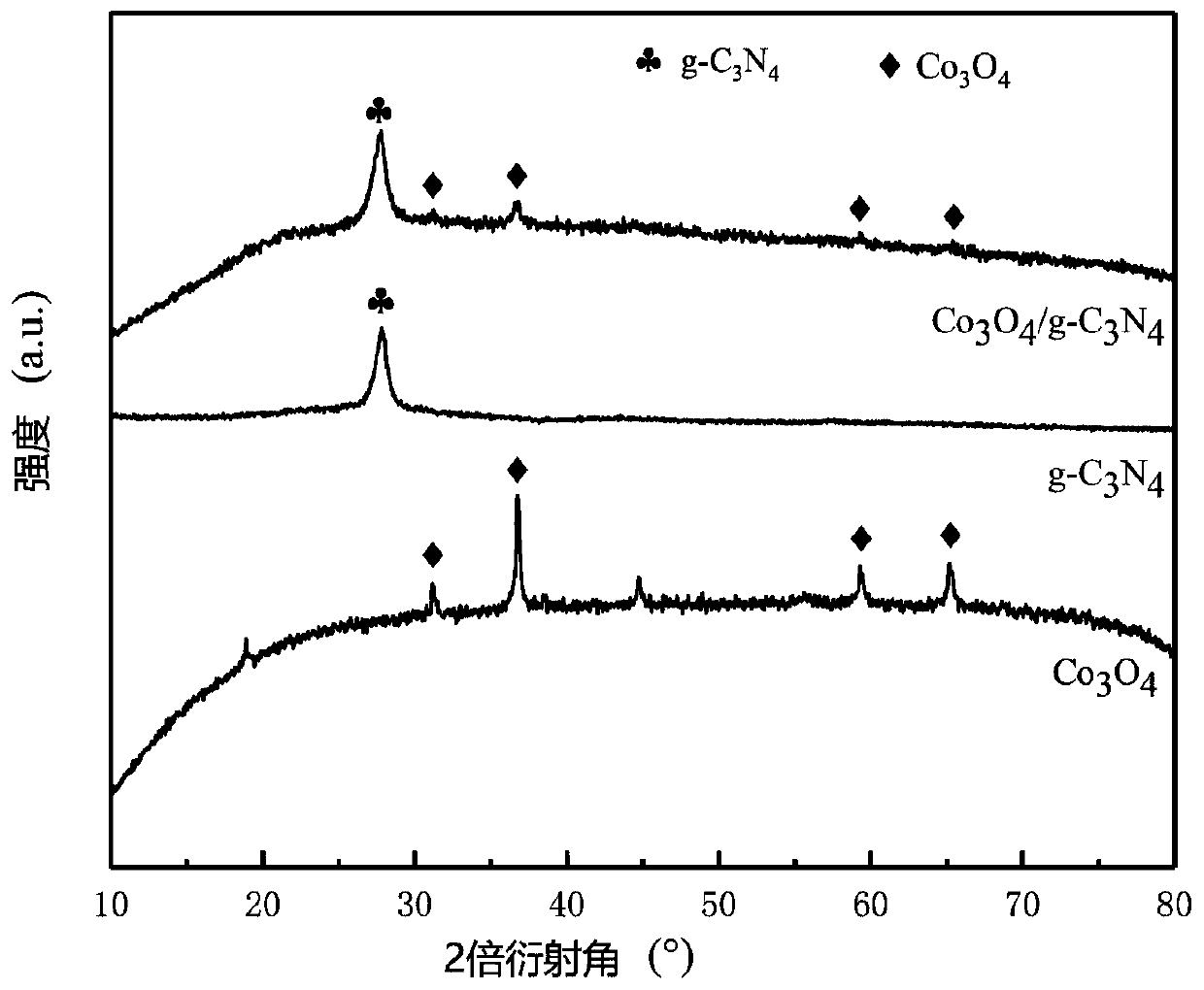

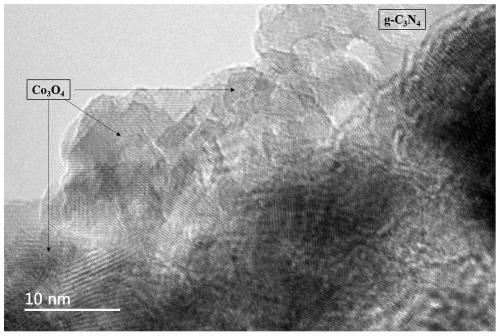

[0036] Modification of tricobalt tetroxide: (1) Weigh 1.5g cobalt nitrate hexahydrate and dissolve it in 10ml deionized water, put on a magnetic stirrer, weigh 3g graphite phase ca...

Embodiment 2

[0041] A carbon-based adsorbent for mercury removal, obtained by a preparation method comprising the following steps:

[0042] Preparation of graphite-phase carbon nitride: (1) Weigh 10 g of melamine at room temperature and place it in a cylindrical crucible, place the crucible in a muffle furnace, set the heating rate at 15°C / min to 600°C, and calcinate for 2 hours, After it was naturally cooled to room temperature, the crucible was taken out, and the bulk solid obtained by calcination was recorded as B, and B was fully ground in an agate mortar.

[0043] (2) Put B in a crucible, heat up to 600°C at a heating rate of 15°C / min, calcinate for 3 hours, and cool naturally to room temperature to obtain graphitic carbon nitride C.

[0044] Modification of tricobalt tetroxide: (1) take 2g cobalt nitrate hexahydrate and dissolve it in 15ml deionized water, put on a magnetic stirrer, weigh 6g graphite phase carbon nitride powder C while stirring, the stirring speed is 30r / min, stir T...

Embodiment 3

[0047] A carbon-based adsorbent for mercury removal, obtained by a preparation method comprising the following steps:

[0048] Preparation of graphite-phase carbon nitride: (1) Weigh 7 g of melamine at room temperature and place it in a cylindrical crucible, place the crucible in a muffle furnace, set the heating rate at 5°C / min to 400°C, and calcinate for 4 hours, After it was naturally cooled to room temperature, the crucible was taken out, and the bulk solid obtained by calcination was recorded as B, and B was fully ground in an agate mortar.

[0049] (2) Put B in a crucible, heat up to 400°C at a heating rate of 5°C / min, calcinate for 5 hours, and cool naturally to room temperature to obtain graphitic carbon nitride C.

[0050] Modification of tricobalt tetroxide: (1) Weigh 3.5g cobalt nitrate hexahydrate and dissolve it in 10ml deionized water, put on a magnetic stirrer, weigh 3.5g graphite phase carbon nitride powder C while stirring, and the stirring speed is 50r / min ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com