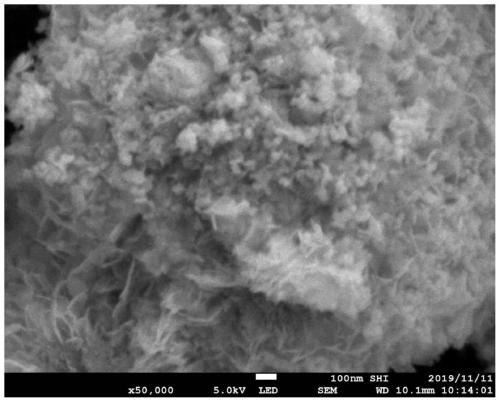

Preparation method of flower-ball-shaped bismuth oxyiodide-titanium dioxide heterojunction photocatalyst, and product thereof

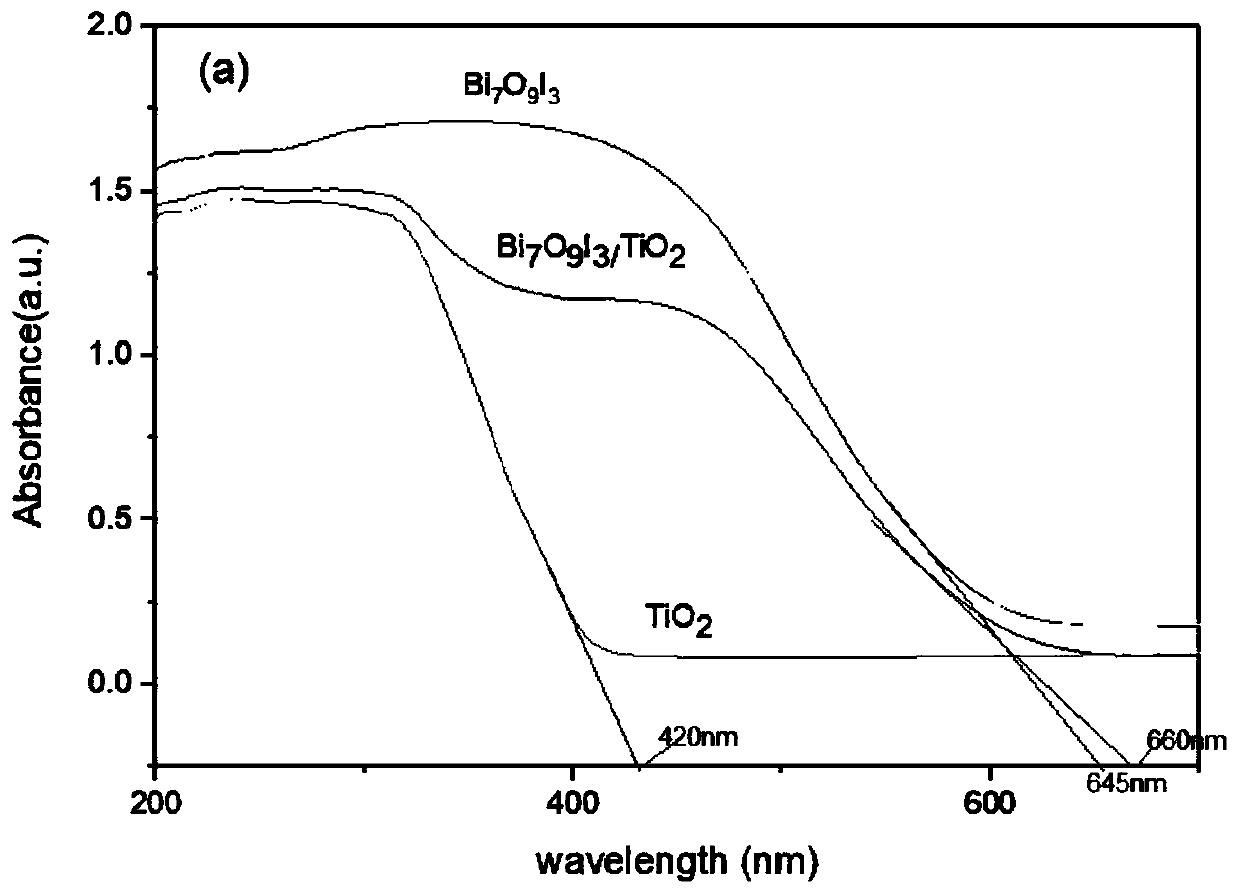

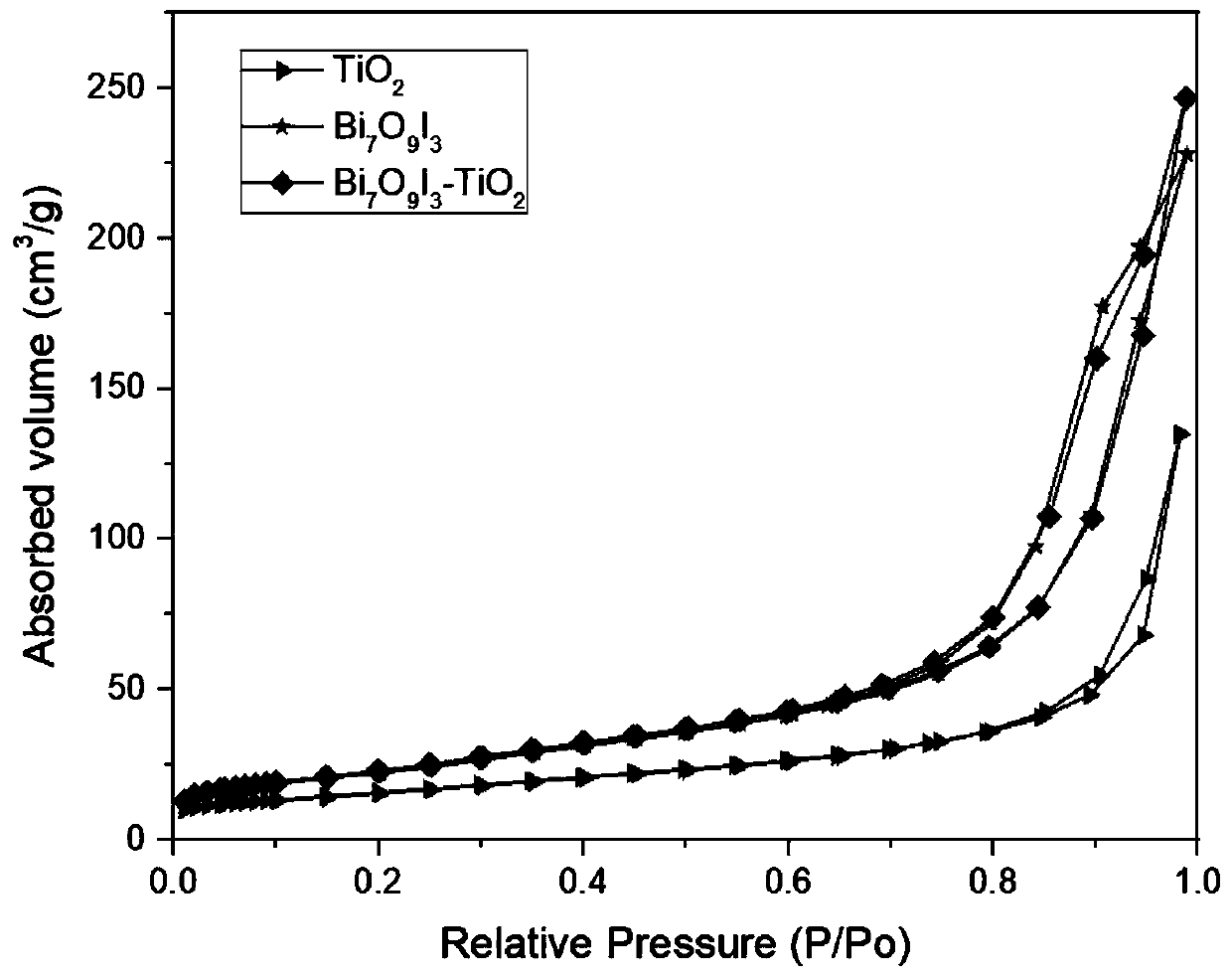

A technology of titanium dioxide and bismuth oxyiodide, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low carrier transport efficiency, insufficient light absorption, small specific surface area, etc. Achieve the effects of promoting electron-hole separation ability, broad application potential, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing a spherical bismuth oxyiodide-titanium dioxide heterojunction photocatalyst:

[0030] (1) Take titanium dioxide powder P25 powder, immerse it in ethanol for 1 hour, take it out, put it in a drying oven at 70°C for 10 hours, put it in a muffle furnace and calcinate it at 220°C at a heating rate of 3°C / min for 2.5 Take it out after 1 hour to get calcined titanium dioxide.

[0031] (2) Take bismuth nitrate pentahydrate and evenly disperse it in ethylene glycol to obtain bismuth nitrate pentahydrate ethylene glycol mixed solution, disperse the calcined titanium dioxide into bismuth nitrate pentahydrate ethylene glycol mixed solution, stir at 1500rpm for 3h Obtain mixed solution a; Described mixed solution a, wherein, the molar volume ratio of bismuth nitrate pentahydrate and ethylene glycol is 1:10 in mmol:mL, and the mass volume ratio of titanium dioxide and ethylene glycol after calcining is in g:mL Count as 1:15.

[0032]...

Embodiment 2

[0039] This embodiment provides a method for preparing a spherical bismuth oxyiodide-titanium dioxide heterojunction photocatalyst:

[0040] (1) Take titanium dioxide powder P25 powder, immerse it in ethanol for 1 hour, take it out, put it in a drying oven at 70°C for 10 hours, put it in a muffle furnace and calcinate it at 220°C at a heating rate of 3°C / min for 2.5 Take it out after 1 hour to get calcined titanium dioxide.

[0041] (2) Take bismuth nitrate pentahydrate and evenly disperse it in ethylene glycol to obtain bismuth nitrate pentahydrate ethylene glycol mixed solution, disperse the calcined titanium dioxide into bismuth nitrate pentahydrate ethylene glycol mixed solution, stir at 1000rpm for 3h Obtain mixed solution a; Described mixed solution a, wherein, the molar volume ratio of bismuth nitrate pentahydrate and ethylene glycol is 1:10 in mmol:mL, and the mass volume ratio of titanium dioxide and ethylene glycol after calcining is in g:mL Count as 1:15.

[0042]...

Embodiment 3

[0045] This embodiment provides a method for preparing a spherical bismuth oxyiodide-titanium dioxide heterojunction photocatalyst:

[0046] (1) Take titanium dioxide powder P25 powder, immerse it in ethanol for 1 hour, take it out, put it in a drying oven at 70°C for 10 hours, put it in a muffle furnace and calcinate it at 220°C at a heating rate of 3°C / min for 2.5 Take it out after 1 hour to get calcined titanium dioxide.

[0047] (2) Take bismuth nitrate pentahydrate and disperse evenly in ethylene glycol to obtain bismuth nitrate pentahydrate ethylene glycol mixed solution, disperse the calcined titanium dioxide into bismuth nitrate pentahydrate ethylene glycol mixed solution, stir at 1500rpm for 3h Obtain mixed solution a; Described mixed solution a, wherein, the molar volume ratio of bismuth nitrate pentahydrate and ethylene glycol is 1:10 in mmol:mL, and the mass volume ratio of titanium dioxide and ethylene glycol after calcining is in g:mL Count as 1:15.

[0048] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com