Bag printing technology adopting environment-friendly water-based ink

An environmentally friendly and water-based technology, applied in printing, ink, and post-processing of printing, etc., can solve the problems of separation and poor adhesion between the outer shell of the plastic film that cannot protect the luggage, the water-based environmental protection ink, and the outer shell of the plastic sealing film. Optimized drying time and temperature, good wetting and leveling, good printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

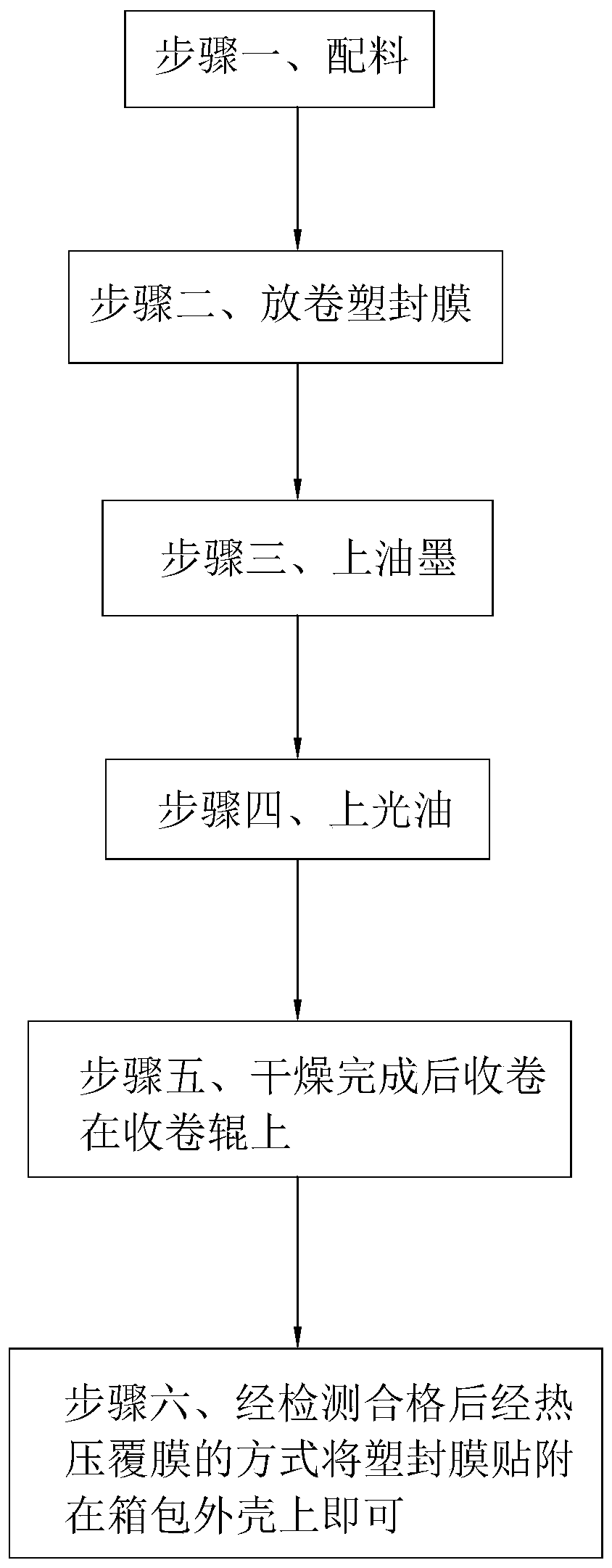

[0039] Embodiment 1: a kind of bag printing process that adopts water-based environmental protection ink, as figure 1 shown, including the following steps:

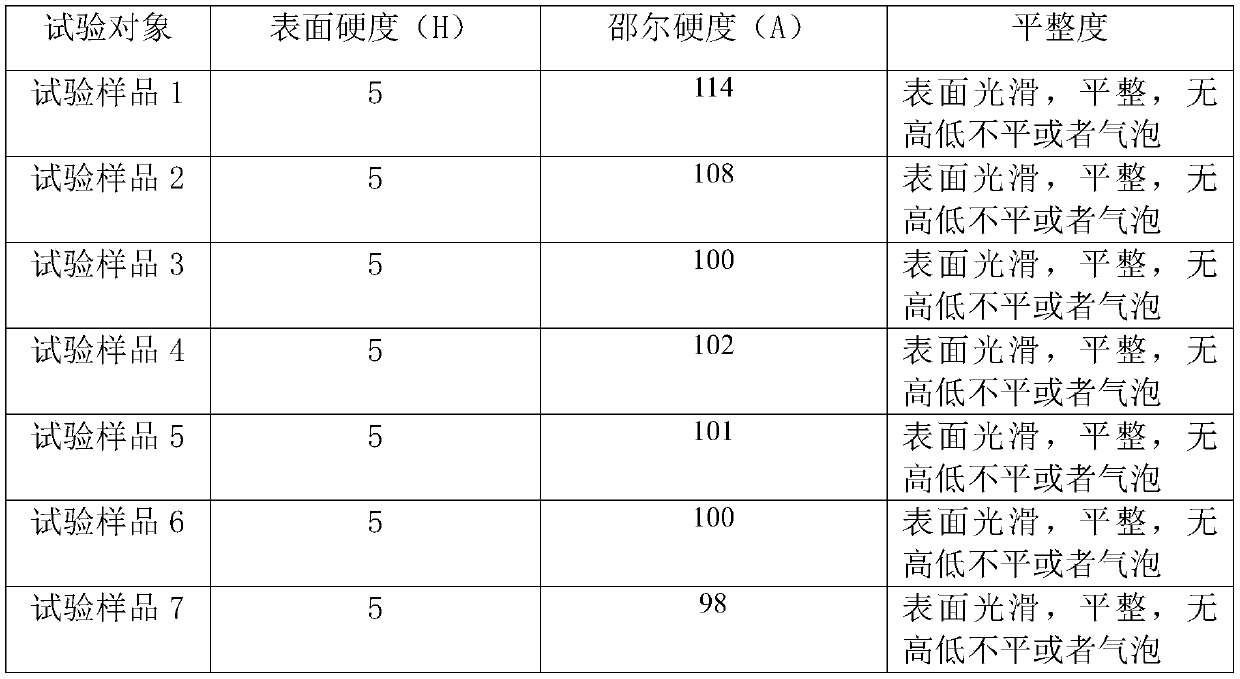

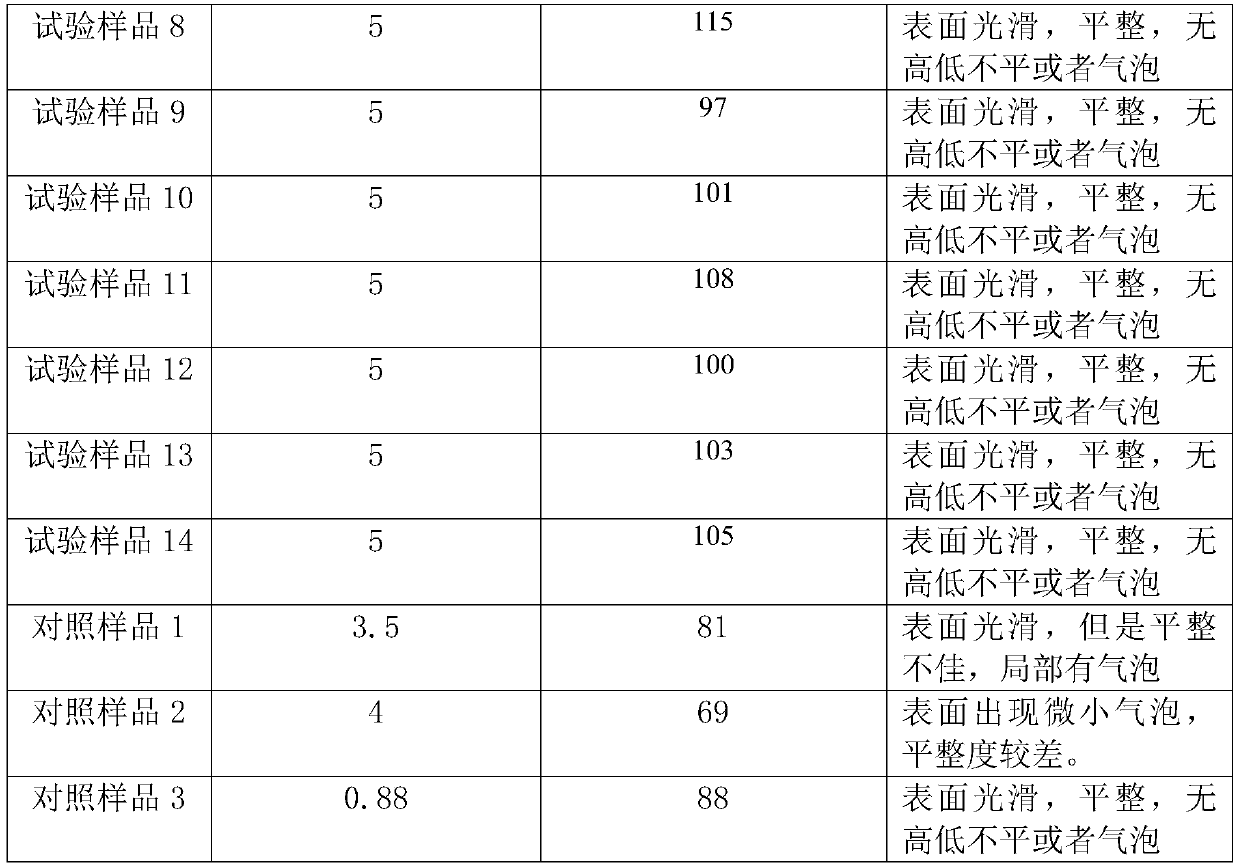

[0040] Step 1, ingredients: the raw materials in the water-based environmental protection ink layer, in parts by weight, include the following components: 25 parts of 870 type acrylic resin liquid; 10 parts of water; 5 parts of ethanol; 5 parts of propylene glycol butyl ether; 5 parts of triethylamine 1 part; 15 parts of pigment; 0.3 part of GPE defoamer; 1 part of water-based dispersant 760W (Sansheng Chemical). Wherein, the pigment is selected from 10 parts of too red powder and 5 parts of titanium dioxide; the varnish is selected from UV varnish.

[0041] Step 2: Unwind the plastic film.

[0042] Step 3. Ink application: On one side of the plastic film, three layers of water-based environmentally friendly ink layers are coated with an RG-3A high-speed gravure printing machine (Ruiguang Printing Machinery); The cloth...

Embodiment 2

[0046] Embodiment 2: a kind of bag printing process that adopts water-based environmental protection ink, comprises following operation steps:

[0047] Step 1, ingredients: the raw materials in the water-based environmental protection ink layer, in parts by weight, include the following components: 30 parts of 870 type acrylic resin liquid; 15 parts of water; 8 parts of ethanol; 8 parts of propylene glycol butyl ether; 8 parts of triethylamine 20 parts; 20 parts of pigment; 0.5 part of di-GPE defoamer; 2 parts of water-based dispersant 760W (Sansheng Chemical). Wherein, the pigment is selected from 10 parts of too red powder, 20 parts of titanium dioxide; the varnish is selected from UV varnish.

[0048] Step 2: Unwind the plastic film.

[0049]Step 3. Applying ink: On one side of the plastic film, two layers of water-based environmental protection ink are coated with an RG-3A high-speed gravure printing machine (Ruiguang Printing Machinery); the viscosity of the glazing oil ...

Embodiment 3

[0053] Embodiment 3: a kind of bag printing process that adopts water-based environmental protection ink, comprises following operation steps:

[0054] Step 1. Ingredients: The raw materials in the water-based environmentally friendly ink layer, in parts by weight, include the following components:

[0055] 35 parts of 870 type acrylic resin liquid; 20 parts of water; 10 parts of ethanol; 10 parts of propylene glycol butyl ether; 10 parts of triethylamine; 30 parts of pigment; 0.8 parts of GPE defoamer; Wherein, the pigment is selected from 10 parts of too red powder and 5 parts of titanium dioxide; the varnish is selected from UV varnish.

[0056] Step 2. Unwind the plastic film.

[0057] Step 3. Applying ink: On one side of the plastic film, a layer of water-based environmental protection ink is coated by an RG-3A high-speed gravure printing machine (Ruiguang Printing Machinery); the viscosity of the glazing oil is about 20 seconds (20°C). The cloth weight is 5g / m 2 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com