In-station sulfur-removal skid-mounted device for oil field sewage with high hydrogen sulfide content and method thereof

A technology with high content of hydrogen sulfide and oilfield sewage, applied in chemical instruments and methods, water/sewage treatment, neutralized water/sewage treatment, etc. Significant economic and social benefits, reducing environmental pollution, and improving the effect of treatment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

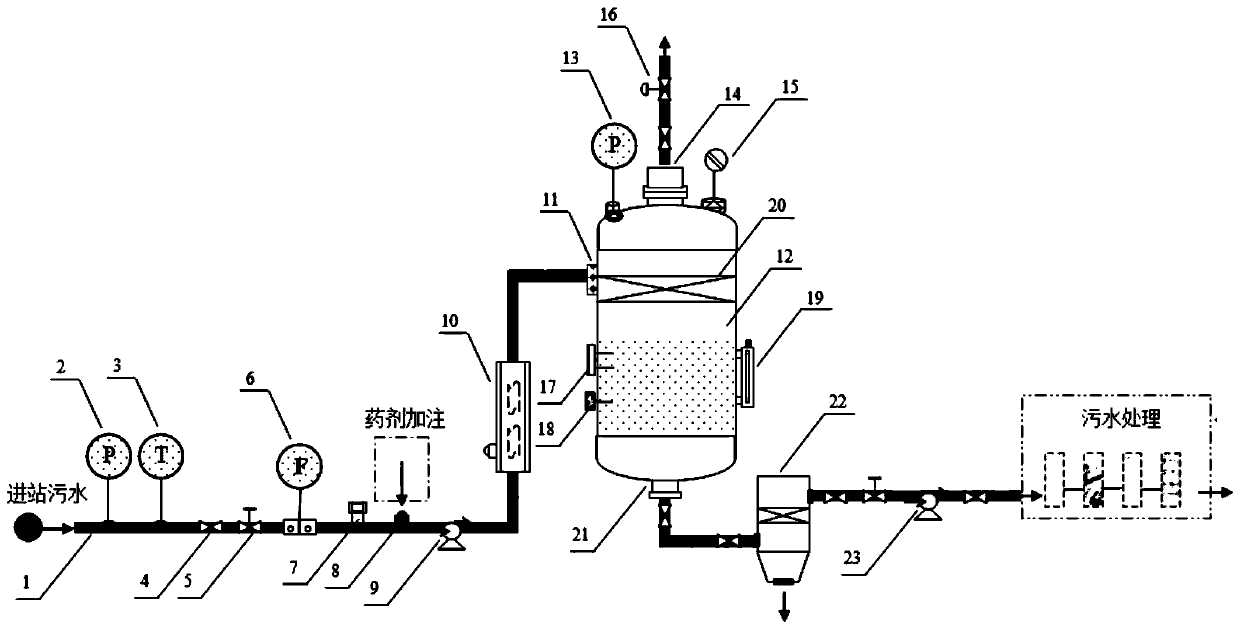

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0028] Such as figure 1 As shown, a skid-mounted desulfurization device in a high hydrogen sulfide oilfield sewage combined station includes a desulfurization tank 12, a sewage pipeline 1, an exhaust pipeline and a sewage discharge pipeline. Among them, the desulfurization tank body 12 is connected to the incoming sewage through the sewage pipeline 1, and the sewage pipeline 1 is provided with a first pressure gauge 2, a thermometer 3, a stop valve 4, a regulating valve 5, a flow meter 6, and a pipeline-type online pH Meter 7, dosing port 8, lift pump 9, tubular mixer 10, sewage water inlet 11, desulfurization tank 12 through the sewage discharge pipeline to connect valves, solid-liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com